Method for preparing molybdenum disulfide-doped graphene fibers

A graphene fiber and molybdenum disulfide technology, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and paper making, can solve the complex processing technology of composite graphene fiber, poor macroscopic assembleability, long production cycle and other problems , to achieve the effect of easy industrial production, low equipment requirements and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 20mg of molybdenum disulfide, 200mg of graphite oxide, add 10g of distilled water, ultrasonicate for 2h, add 600mg of sodium deoxycholate, stir magnetically at a speed of 600r / min for 24h, and prepare sodium deoxycholate / molybdenum disulfide-oxide Graphene gel. Use a syringe pump to extrude the gel into a watch glass containing absolute ethanol at a speed of 1 mL / min, and replace the absolute ethanol 10 times in time. After washing for 3 hours, suck out the absolute ethanol. After the absolute ethanol evaporates, 2 hours Finally, molybdenum disulfide-graphene oxide fibers are obtained. The prepared molybdenum disulfide-graphene oxide fibers were added with hydroiodic acid for reduction for 3 hours to obtain graphene fibers. Washing 5 times with ultrapure water, standing for 6 hours to obtain hydrated molybdenum disulfide nanosheet-graphene fibers, and drying for 2 hours again to obtain graphene fibers doped with molybdenum disulfide nanosheets.

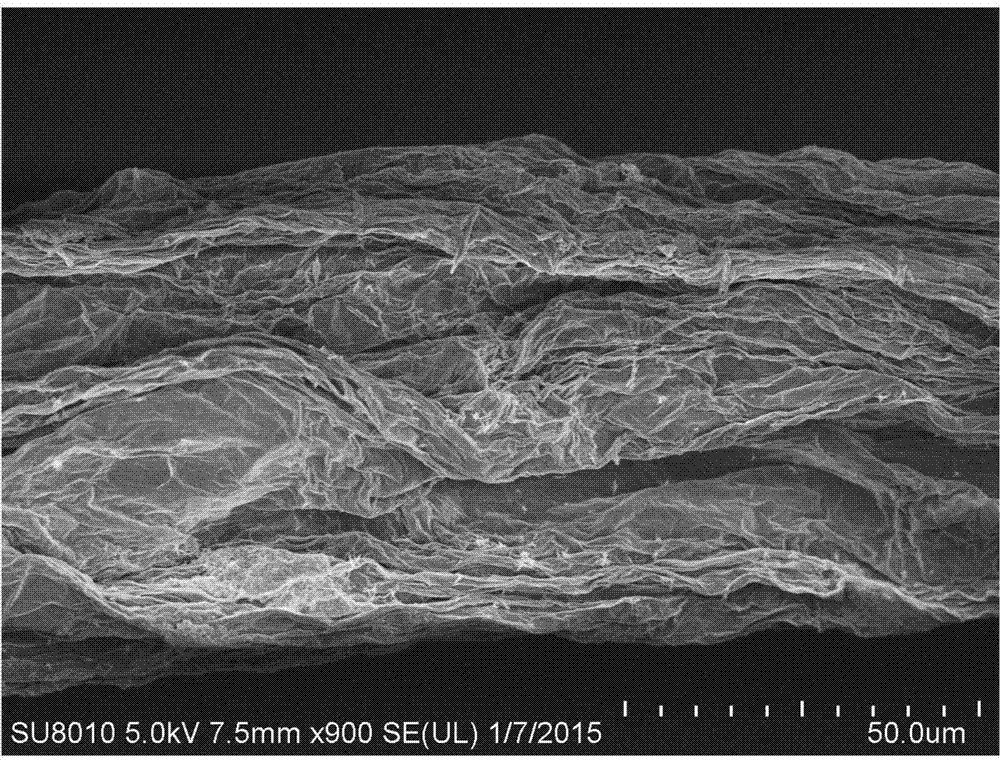

[0028] like f...

Embodiment 2

[0030] Weigh 40mg of molybdenum disulfide, 200mg of graphite oxide, add 10g of distilled water, ultrasonicate for 1h, add 600mg of sodium deoxycholate, stir magnetically at a speed of 300r / min for 20h, and prepare sodium deoxycholate / molybdenum disulfide-oxidized Graphene gel. Use a syringe pump to extrude the gel into a watch glass containing absolute ethanol at a speed of 0.6 mL / min, and replace the absolute ethanol 8 times in time. After washing for 4 hours, suck out the absolute ethanol. After the absolute ethanol evaporates, After 1 h, graphene oxide fibers doped with molybdenum disulfide were obtained. The prepared graphene oxide fibers doped with molybdenum disulfide were added with hydroiodic acid and reduced for 2 hours to obtain graphene fibers. Washing with ultrapure water for 3 times, standing for 4 hours to obtain hydrated molybdenum disulfide nanosheet-graphene fibers, and drying for 1 hour again to obtain graphene fibers doped with molybdenum disulfide nanoshee...

Embodiment 3

[0032] Weigh 20mg of molybdenum disulfide and 100mg of graphite oxide, add 10g of distilled water, ultrasonicate for 1.5h, add 200mg of sodium deoxycholate, stir magnetically at a speed of 500r / min for 24h, and prepare sodium deoxycholate / molybdenum disulfide - Graphene oxide gel. Use a syringe pump to extrude the gel into a watch glass containing absolute ethanol at a speed of 0.8 mL / min, and replace the absolute ethanol 5 times in time. After washing for 3.5 hours, suck out the absolute ethanol, and wait for the absolute ethanol to evaporate completely. , Graphene oxide fibers doped with molybdenum disulfide were obtained after 1.5h. The prepared graphene oxide fibers doped with molybdenum disulfide were added with hydroiodic acid and reduced for 2.5 hours to obtain graphene fibers. Wash 4 times with ultrapure water, let stand for 5h to obtain hydrated molybdenum disulfide nanosheet-graphene fiber, dry again for 1.5h to obtain graphene fiber doped with molybdenum disulfide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com