Preparation method of novel low-noise EVA (ethylene vinyl acetate copolymer) cable material

A low-noise, cable material technology, used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems such as poor anti-noise performance, inability to use low-noise cables, and limited application scope, to improve anti-noise performance. , the effect of reducing noise value and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

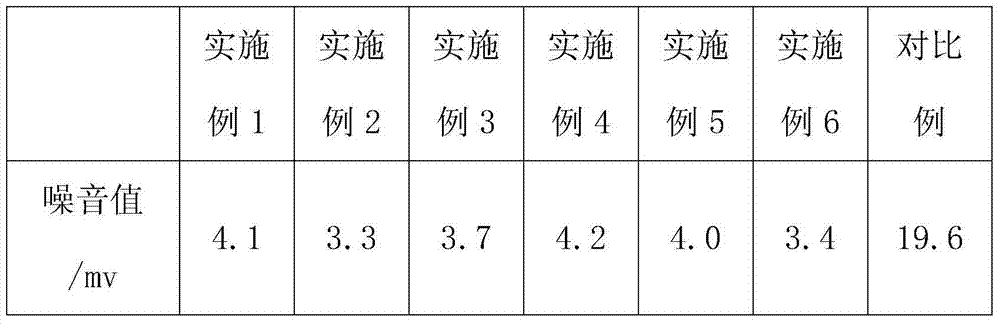

Examples

Embodiment 1

[0025] A new type of low-noise EVA cable material preparation method, the steps are as follows:

[0026] (1) Crush the natural coral with a pulverizer and add it to a 10% sodium hydroxide solution, soak for 2 hours and then move it to an acetone solution for ultrasonic cleaning for 30 minutes, take it out, and dry it at 80°C for 3 hours to obtain coral powder ;

[0027] (2) Ball mill the coral powder obtained in step (1) with a ball mill for 10 hours, add it to a 40% ethanol solution and stir and mix to form a suspension, add polyethylene glycol to the suspension and magnetically stir for 2 hours, then discharge Then it was placed in a vacuum drying oven at 90°C and vacuum dried for 10 hours, taken out, ground, and passed through a 300-mesh sieve to obtain modified coral powder. The weight ratio of coral powder, ethanol solution and polyethylene glycol was 48:48: 1;

[0028] (3) Add the nano boron fiber to the toluene solution and soak for 48 hours, place it in a drying oven to dry...

Embodiment 2

[0031] A new type of low-noise EVA cable material preparation method, its steps are as follows:

[0032] (1) Crush the natural coral with a pulverizer and add it to a 10% sodium hydroxide solution, soak for 2 hours and then move it to an acetone solution for ultrasonic cleaning for 30 minutes, take it out, and dry it at 80°C for 3 hours to obtain coral powder ;

[0033] (2) Ball mill the coral powder obtained in step (1) with a ball mill for 10 hours, add it to a 40% ethanol solution and stir and mix to form a suspension, add polyethylene glycol to the suspension and magnetically stir for 2 hours, discharge After that, it was placed in a vacuum drying box for vacuum drying at 90°C for 10 hours, taken out, ground, and passed through a 300-mesh sieve to obtain modified coral powder. The weight ratio of coral powder, ethanol solution, and polyethylene glycol was 48:48: 1;

[0034] (3) Add the nano boron fiber to the toluene solution and soak for 48 hours, put it in a drying oven to dr...

Embodiment 3

[0037] A new type of low-noise EVA cable material preparation method, its steps are as follows:

[0038] (1) Crush the natural coral with a pulverizer and add it to a 10% sodium hydroxide solution, soak for 2 hours and then move it to an acetone solution for ultrasonic cleaning for 30 minutes, take it out, and dry it at 80°C for 3 hours to obtain coral powder ;

[0039] (2) Ball mill the coral powder obtained in step (1) with a ball mill for 10 hours, add it to a 40% ethanol solution and stir and mix to form a suspension, add polyethylene glycol to the suspension and magnetically stir for 2 hours, discharge After that, it was placed in a vacuum drying box for vacuum drying at 90°C for 10 hours, taken out, ground, and passed through a 300-mesh sieve to obtain modified coral powder. The weight ratio of coral powder, ethanol solution, and polyethylene glycol was 48:48: 1;

[0040] (3) Add the nano boron fiber to the toluene solution and soak for 48 hours, place it in a drying oven to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com