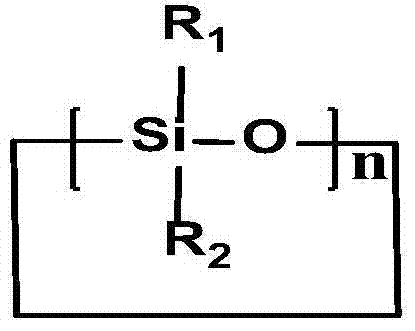

Method for synthesizing polysiloxane miniemulsion by utilizing microlatex seeds under single emulgator

A technology of microlatex seeds and polysiloxane, which is applied in polysiloxane microemulsions and application fields, can solve problems such as cumbersome corresponding processes, and achieve the effects of simplifying process steps, reducing production costs, and simplifying post-processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

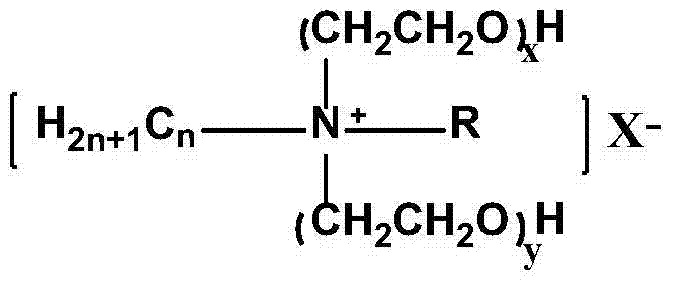

[0043] (1) Take 2.4 g of octadecyldipolyoxyethylene benzyl ammonium chloride (oxyethylene group x+y=15 in the structure), add 67.6 g of deionized water, stir mechanically until it is completely dissolved, add 3 g of octamethyl Cyclotetrasiloxane (D 4 ), make it mix evenly by stirring, then carry out pre-emulsification by 600r / min mechanical shearing homogeneous 25min, add 1.25g mass fraction after emulsification is 40% potassium hydroxide solution, under the condition of 450r / min at the rotating speed, heat up to 70°C and react for 20 minutes to prepare polysiloxane microlatex seeds.

[0044](2) Add 27g D dropwise at 0.225g / min to the polysiloxane microlatex seeds of the above (1). 4 , keep the rotational speed at 450r / min and the reaction temperature at 70°C, continue the reaction for 1h after the dropwise addition, and neutralize with acid to pH=7 after cooling to obtain polysiloxane miniemulsion.

[0045] (3) The particle size of the miniemulsion measured by the dynamic l...

Embodiment 2

[0047] (1) Take 3.6 g of dodecyl bispolyoxyethylene benzyl ammonium bromide (oxyethylene group x+y=15 in the structure), add 101.4 g of deionized water, stir mechanically until it is completely dissolved, add 4 g of octamethyl Cyclotetrasiloxane (D 4 ), then carry out pre-emulsification by 1000r / min mechanical shear homogenization for 10min, after the emulsification is completed, add 1.875g mass fraction of 40% sodium hydroxide solution, under the condition of 500r / min, heat up to 80°C, react for 30min, The polysiloxane microlatex seeds were prepared.

[0048] (2) Add 36g D dropwise at 0.45g / min to the polysiloxane microlatex seeds 4 , keep the rotational speed at 500r / min and the reaction temperature at 80°C, continue the reaction for 2h after the dropwise addition, and neutralize with acid to pH=7 after cooling to obtain polysiloxane miniemulsion.

[0049] (3) The particle size of the miniemulsion measured by the dynamic light scattering method is 77.52nm (Z-Average), and ...

Embodiment 3

[0051] (1) Take 4.8 g of octadecyldipolyoxyethylene benzyl ammonium chloride (oxyethylene group x+y=15 in the structure) and add 135.2 g of deionized water, stir mechanically until it dissolves completely, add 6 g of octamethyl Cyclotetrasiloxane (D 4 ), make it mix uniformly by stirring, then carry out pre-emulsification by 1200r / min mechanical shearing homogeneous 20min, add 3g mass fraction after emulsification and be 20% potassium hydroxide solution, under the condition of 350r / min, be warming up to React at 85°C for 20 minutes to prepare polysiloxane microlatex seeds.

[0052] (2) Add 54g D dropwise at 0.9g / min to the above polysiloxane microlatex seeds 4 , keep the rotational speed at 350r / min and the reaction temperature at 85°C, continue the reaction for 4h after the dropwise addition, and neutralize with acid to pH=7 after cooling to obtain polysiloxane miniemulsion.

[0053] (3) The particle size of the miniemulsion measured by the dynamic light scattering method i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com