Spherical cathode numerical control electrochemical machining machine tool

An electrolytic machining machine tool and cathode technology, which is applied to electric machining equipment, electrochemical machining equipment, machining electrodes, etc., can solve the problem of copy-type machining replication accuracy, repetition accuracy is not too high, copy-type electrolytic machining is difficult to complete processing, forming cathodes Design and manufacturing difficulties, etc., to achieve the effect of a wide range of applicable processing, large processing flexibility, and good service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

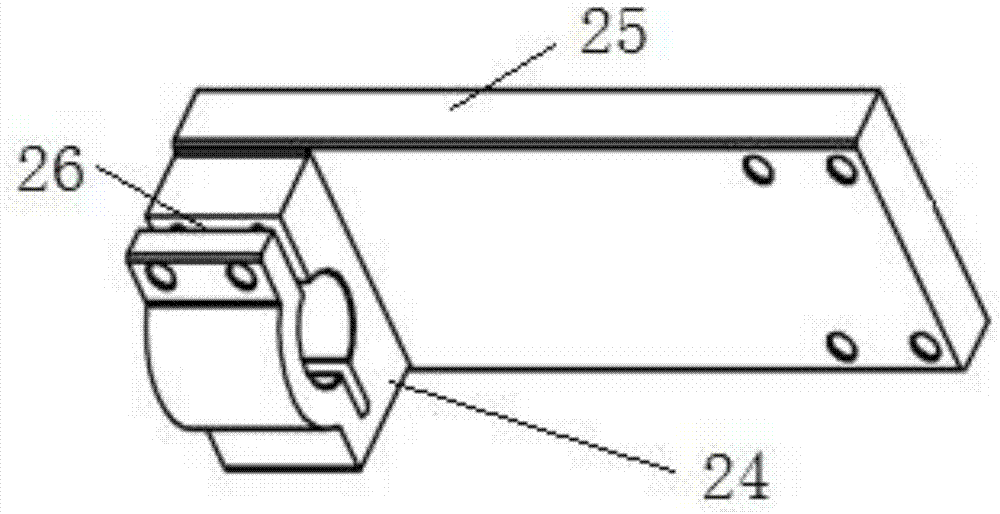

[0030] Embodiment 1: as Figure 1-3 Shown: a spherical cathode numerical control electrolytic machining machine tool, including a bed 1, the bed 1 has a linear circular rail 3,

[0031] A workbench 2 is installed on the bed, and an insulating plate 4 is arranged on the workbench 2, and the insulating plate 4 is airtightly connected with the processing box 5 to realize the insulation of the workbench 2 and the workpiece in the processing box 5;

[0032] The linear circular rail 3 is provided with a three-axis moving mechanism, the Z-direction moving mechanism 9 in the three-axis movement mechanism is fixedly connected with the C-direction rotating mechanism 11, and the C-direction rotating mechanism 11 has a C-direction servo motor 10 and a worm gear transmission device, The C-direction servo motor 10 drives the fixture to rotate through the worm gear to realize the rotation of the spherical cathode 13 .

[0033] The spherical cathode 13 is a round rod-shaped structure with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com