Rabbit granulated feed and preparation method and application thereof

A technology of pellet feed and feed, applied in the application, animal feed, animal feed and other directions, can solve the problems of high breeding cost, inconvenient transportation, high feed price, and achieve the effect of rich nutrition, wide range of use and smooth particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Raw material collection: cut out pest-free, fresh twigs, fruits and leaves of the banyan tree, and remove impurities and sediment;

[0036] (2) green material pulverization: the raw material after removing impurity silt in step (1) is carried out primary pulverization by green grass pulverizer, then raw material is dried, obtains raw material powder;

[0037] (3) Grinding of dry material: the primary material powder dried in the step (2) is carried out secondary pulverization by a feed mill to form a fine powder, and obtain twig, fruit and leaf powder of Ficus chrysalis;

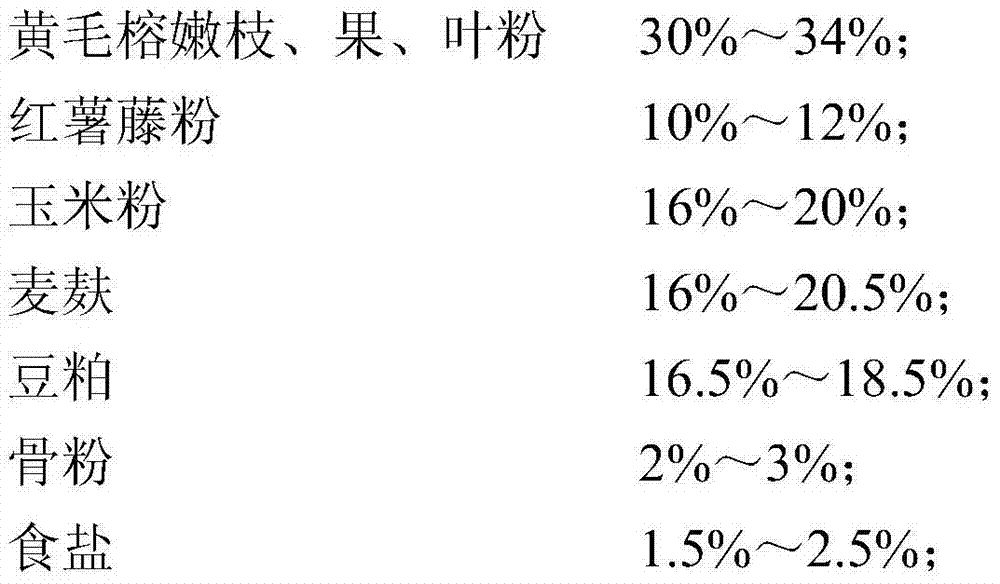

[0038] (4) The following raw material components by mass percentage are mixed and stirred evenly by a feed mixer: 30% of banyan twig, fruit and leaf powder, 12% of sweet potato vine powder, 20% of corn flour, 16% of wheat bran, 18.5% soybean meal, 2% bone meal, 1.5% table salt;

[0039] (5) Granulation: Granulate the raw material components mixed in step (4): before starting the machine, put a sm...

Embodiment 2

[0042] (1) Raw material collection: cut out pest-free, fresh twigs, fruits and leaves of the banyan tree, and remove impurities and sediment;

[0043] (2) green material pulverization: the raw material after removing impurity silt in step (1) is carried out primary pulverization by green grass pulverizer, then raw material is dried, obtains raw material powder;

[0044] (3) Grinding of dry material: the primary material powder dried in the step (2) is carried out secondary pulverization by a feed mill to form a fine powder, and obtain twig, fruit and leaf powder of Ficus chrysalis;

[0045] (4) The following raw material components by mass percentage are mixed and stirred evenly by a feed mixer: 32% of banyan twig, fruit and leaf powder, 11% of sweet potato vine powder, 18% of corn flour, 18% of wheat bran, 17.5% soybean meal, 3% bone meal, 2.5% table salt;

[0046] (5) Granulation: Granulate the raw material components mixed in step (4): before starting the machine, put a sm...

Embodiment 3

[0049] (1) Raw material collection: cut out pest-free, fresh twigs, fruits and leaves of the banyan tree, and remove impurities and sediment;

[0050] (2) green material pulverization: the raw material after removing impurity silt in step (1) is carried out primary pulverization by green grass pulverizer, then raw material is dried, obtains raw material powder;

[0051] (3) Grinding of dry material: the primary material powder dried in the step (2) is carried out secondary pulverization by a feed mill to form a fine powder, and obtain twig, fruit and leaf powder of Ficus chrysalis;

[0052] (4) The following raw material components by mass percentage are mixed and stirred evenly by a feed mixer: 34% of banyan twig, fruit and leaf powder, 10% of sweet potato vine powder, 16% of corn flour, 20% of wheat bran, 16.5% soybean meal, 2.5% bone meal, 1.6% table salt;

[0053] (5) Granulation: Granulate the raw material components mixed in step (4): before starting the machine, put a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com