Early spring sweet dew tea and preparation method thereof

A technology for manna tea and tea leaves, which is applied to the field of early spring manna tea and its preparation, can solve the problems that the yield and quality of tea leaves cannot meet the needs of consumers and the like, and achieve the effects of improving the quality and yield of tea leaves, bright apricot green and bright green color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

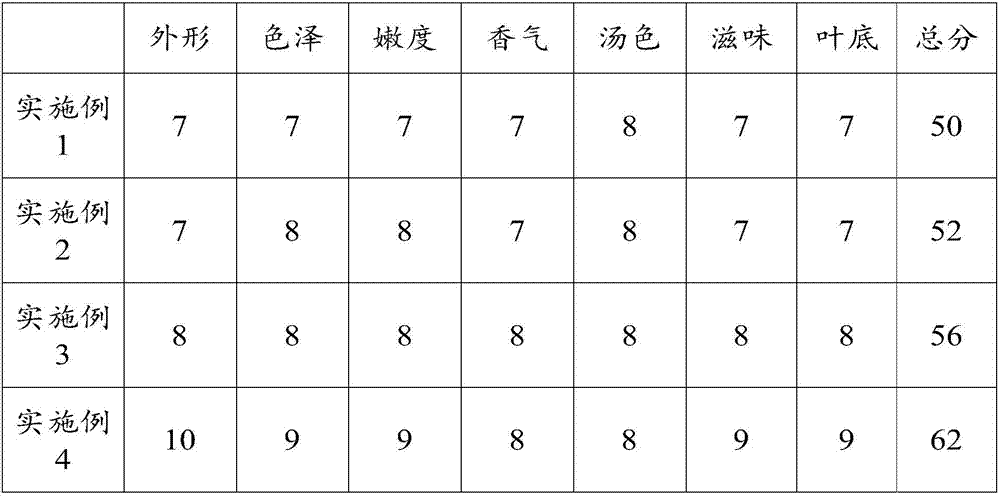

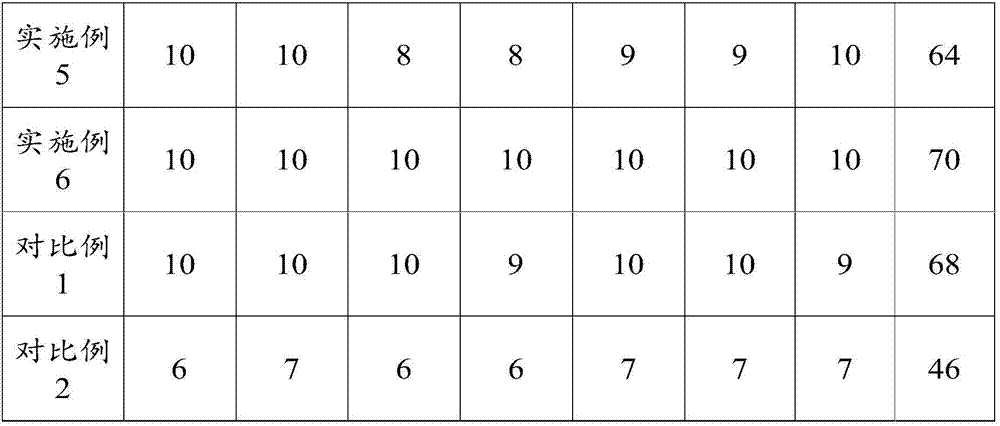

Examples

preparation example Construction

[0013] A kind of preparation method of early spring manna tea provided by the embodiment of the present invention comprises:

[0014] Select the fresh tea leaves with one bud and one leaf first developed before the vernal equinox as raw materials. Among them, the weight of a single bud accounts for 20-30%, and the number is 30-40%; the initial weight of one bud and one leaf accounts for 60-70%, and the number is 50-60%; Count 3 to 8%. The color of the fresh leaves is light yellow-green, the size of the buds and leaves is uniform, and the "four nos" are achieved, that is, no purple buds and leaves, no pests and diseases, no rain and dew water, and no thin buds and leaves. The quality of raw materials makes the processed tea have higher quality.

[0015] Spread the fresh leaves with a net rack or a degreening trough until the tea leaves feel soft when pinched by hand. Specifically, the spreading time is 6-10 hours, and the spreading thickness is 15-17 cm. The dehydration rat...

Embodiment 1

[0027] The present embodiment provides a kind of early spring nectar tea, which is prepared through the following steps:

[0028] The fresh leaves are first steamed, and the leaf temperature is 80°C. The steamed green leaves are directly subjected to drum re-cracking, the temperature of which is 100° C., and the de-enzyming time is 80 s.

[0029] After the finishing treatment, knead for 10 minutes with a tea kneading machine. Dry the tea with a dryer at 100°C for 5 minutes until the water content of the tea leaves is 30%. Re-knead for 20 minutes with a tea kneading machine, and then re-dry with a dryer at 90°C until the water content of the tea leaves is 20%.

[0030] The re-dried tea leaves are put into a drying bucket with a wind temperature of 75°C by using a hot air drying bucket, and the tea leaves are basically shaped by hand and the water content is 10%. When the tea leaves show pekoe, increase the temperature of the pot to 85°C, and knead until the tea sticks are co...

Embodiment 2

[0032] The present embodiment provides a kind of early spring nectar tea, which is prepared through the following steps:

[0033] After the fresh leaves are spread out, they are first steamed and the leaf temperature is 85°C. The steamed green leaves are directly subjected to drum re-cracking, the temperature of which is 110° C., and the de-enzyming time is 80 s.

[0034] After the finishing treatment, use a tea kneading machine to knead for 15 minutes. Preliminary drying with a dryer at 110°C for 15 minutes until the water content of the tea leaves is 40%.

[0035] The rebaked tea leaves are put into a drying bucket with a wind temperature of 85°C by using a hot air drying bucket, and the tea leaves are basically shaped by hand and the water content is 20%. When the tea leaves show pekoe, increase the temperature of the pot to 85°C, and knead until the tea sticks are covered with pekoe, and the water content of the tea is 12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com