Method of simultaneously measuring water content and oil content of oily sludge

A measurement method and technology for water content, applied in the field of material detection, can solve the problems of inaccurate analysis of water content and oil content, time-consuming analysis process, etc., and achieve the effects of short time consumption, high accuracy of results, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention discloses a method for rapidly and accurately measuring the water content and oil content of oily sludge simultaneously. The specific implementation steps are as follows:

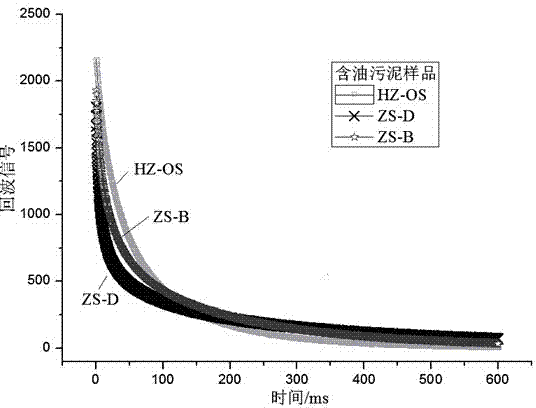

[0021] 1) Sample collection: 31 samples of oily sludge in Zhoushan (ZS-D and ZS-B) and Hangzhou area (HZ-OS) were collected in different batches; in addition, 3 samples were collected in Hangzhou area (HZ-OS) There are 3 oily sludge samples, the sample source is representative of the sampling area, and the number of samples is more than 30.

[0022] 2) Sample measurement: The water content and oil content of 34 samples were measured using the improved Dean-Stark device recommended by the Oil Sands Administration of Alberta, Canada, as reference values for subsequent modeling. The results are shown in Table 1. The 31 samples in Hangzhou and Zhoushan The water content and oil content are shown in Table 2 for the water content and oil content of the three samples in Hangzhou area. From...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com