A vibration detection device and method for a flexible cantilever plate based on binocular vision

A flexible cantilever and detection method technology, applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of cumbersome calculation process, affecting accuracy, high cost, etc., and achieve simple detection operation, improve measurement accuracy, and measure wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

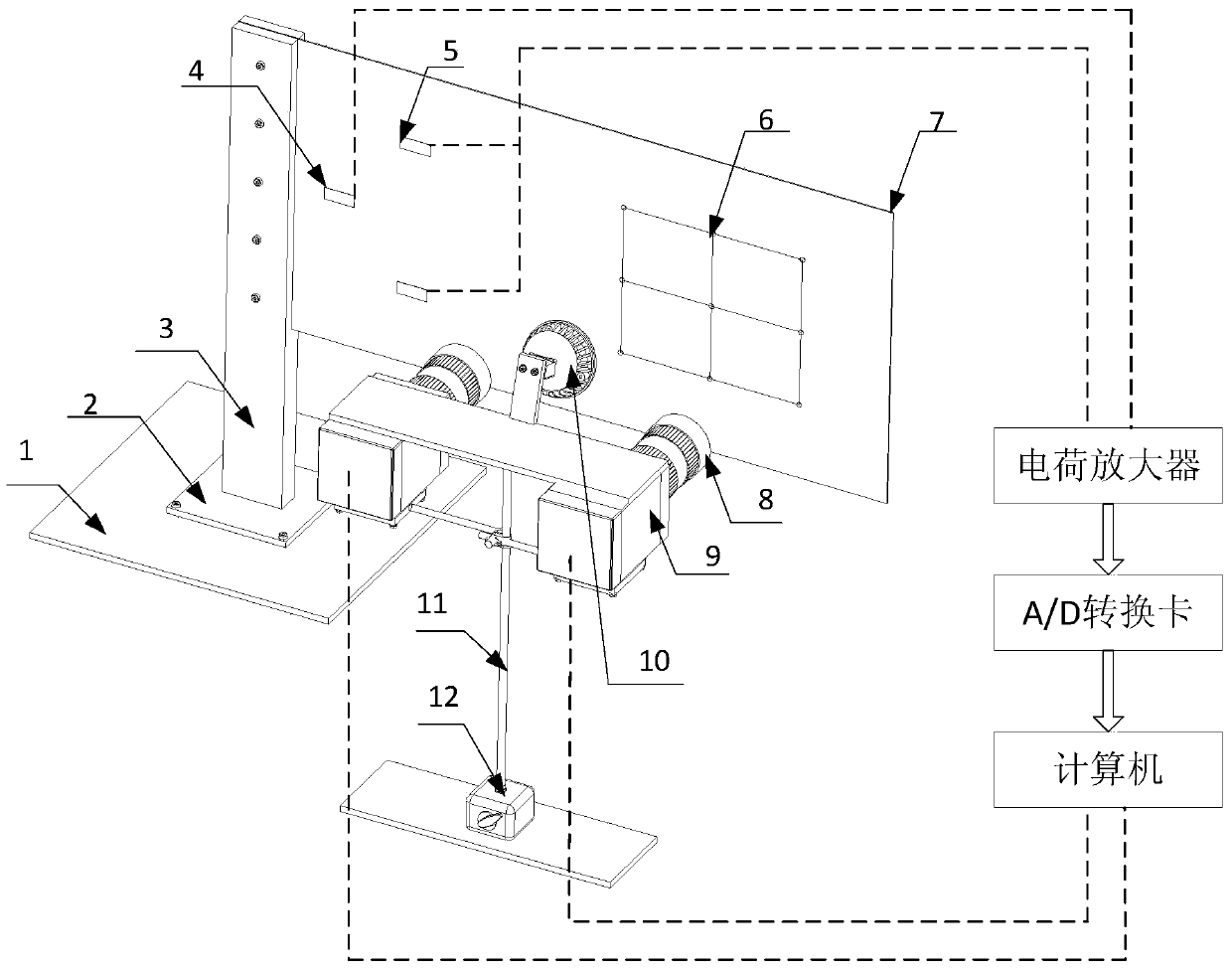

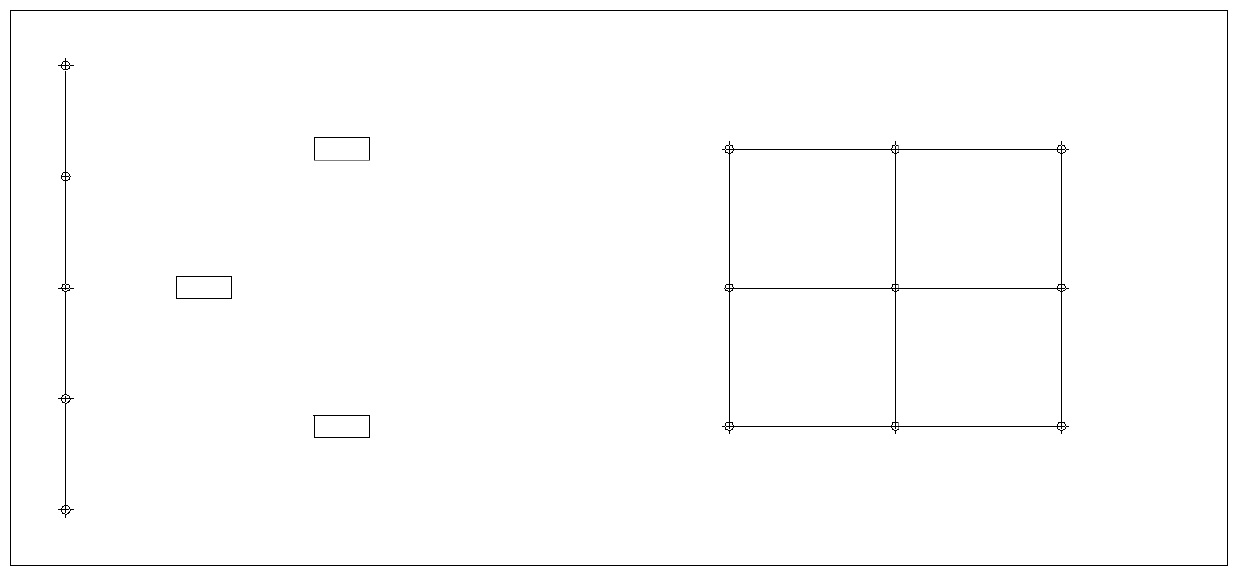

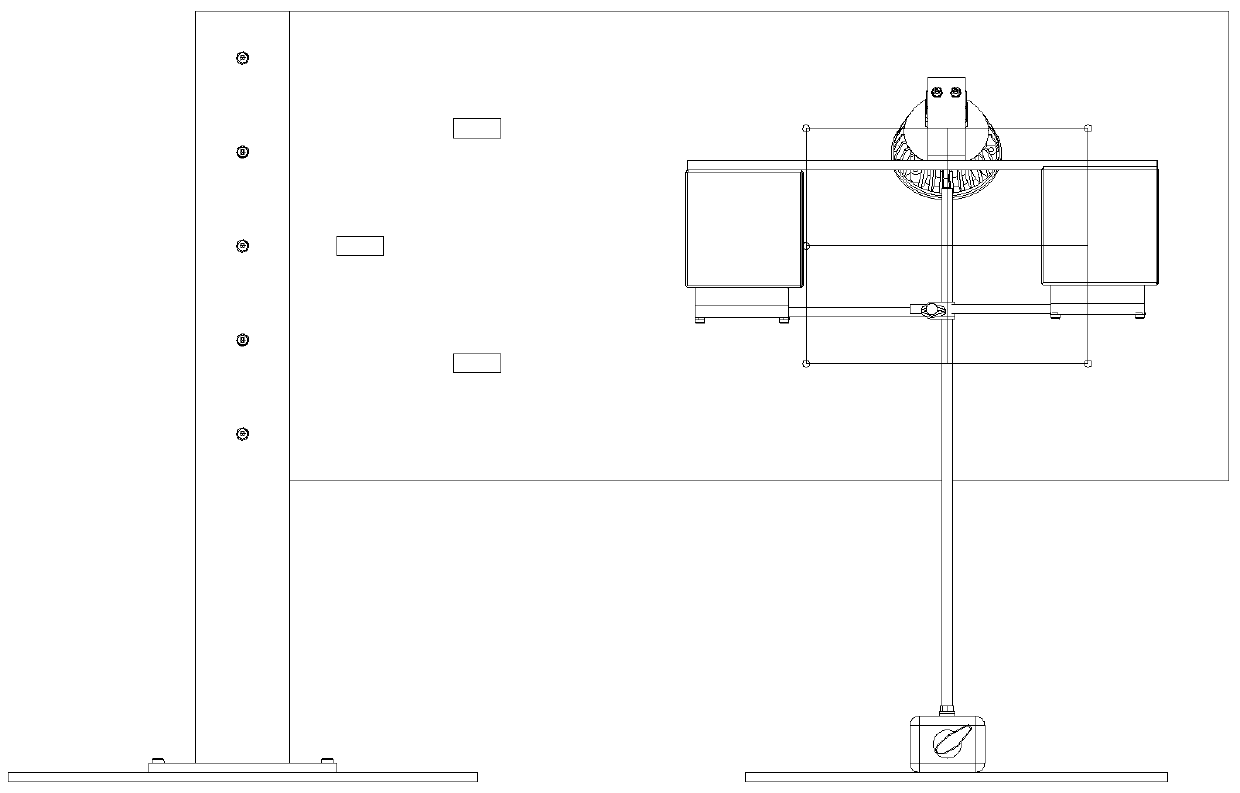

[0043] Such as Figure 1-Figure 5 As shown, a flexible cantilever plate vibration detection device based on binocular vision includes a flexible cantilever plate 7, one end of the flexible cantilever plate 7 is fixed by a mechanical bracket clamping device, called a fixed end, and the other end is a free end. The strain gauge sensor includes two, respectively the first and second resistance strain gauge sensors 4 and 5, which are pasted on the flexible cantilever plate 7, and the mechanical support clamping device 3 is fixed on the fixed rod base 2, and the fixed rod base 2 is fixed on the base 1;

[0044] The first resistance strain gauge sensor 4 includes two resistance strain gauges, which are pasted on the longitudinal centerline near the fixed end of the flexible cantilever plate, and are 50mm away from the fixed end, with a posture angle of 0°, pasted symmetrically on both sides, one piece on each side and connected in parallel ;

[0045] The second resistance strain g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com