Combustion heating system for Stirling engine

A Stirling engine and heating system technology, which is applied in the direction of machines/engines, hot gas variable displacement engine devices, mechanical equipment, etc., can solve problems such as unfavorable applications, increased ignition time of burners, etc., to improve thermal stress conditions, improve Combustion conditions, the effect of reducing the local high temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

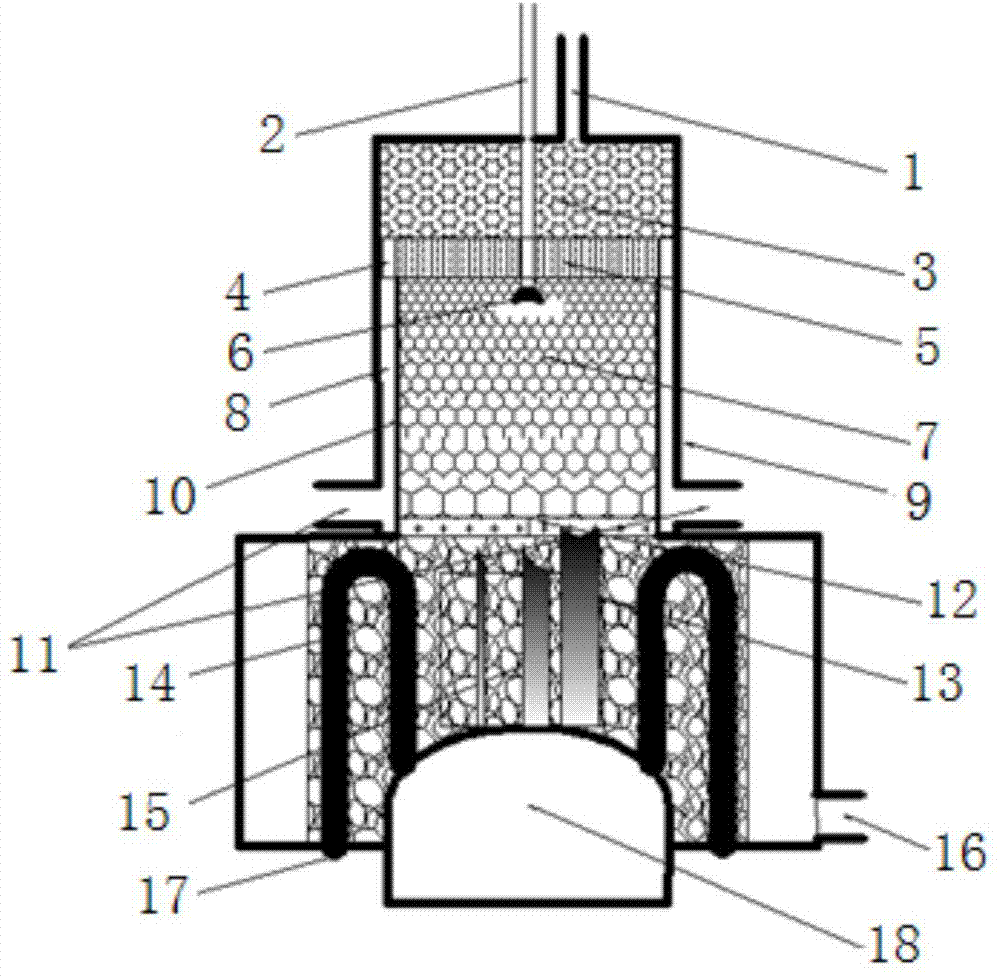

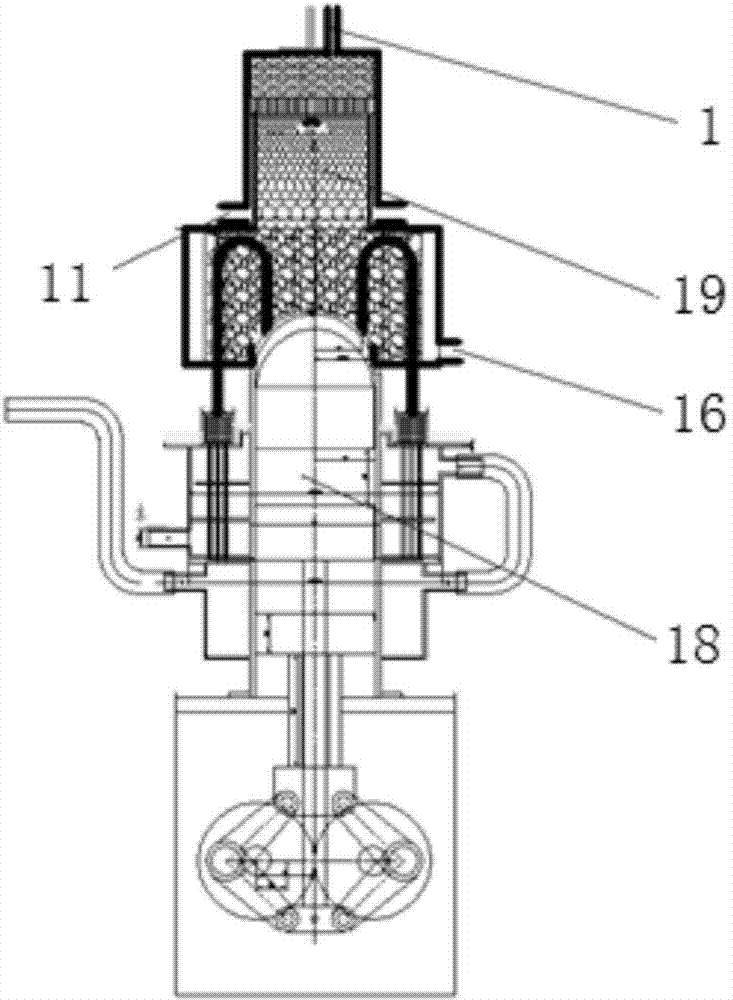

[0035] A kind of combustion heating system 19 of Stirling engine, its structure is as figure 1As shown, it consists of a straight gradient stacked porous media burner and a filled porous media heater arranged up and down.

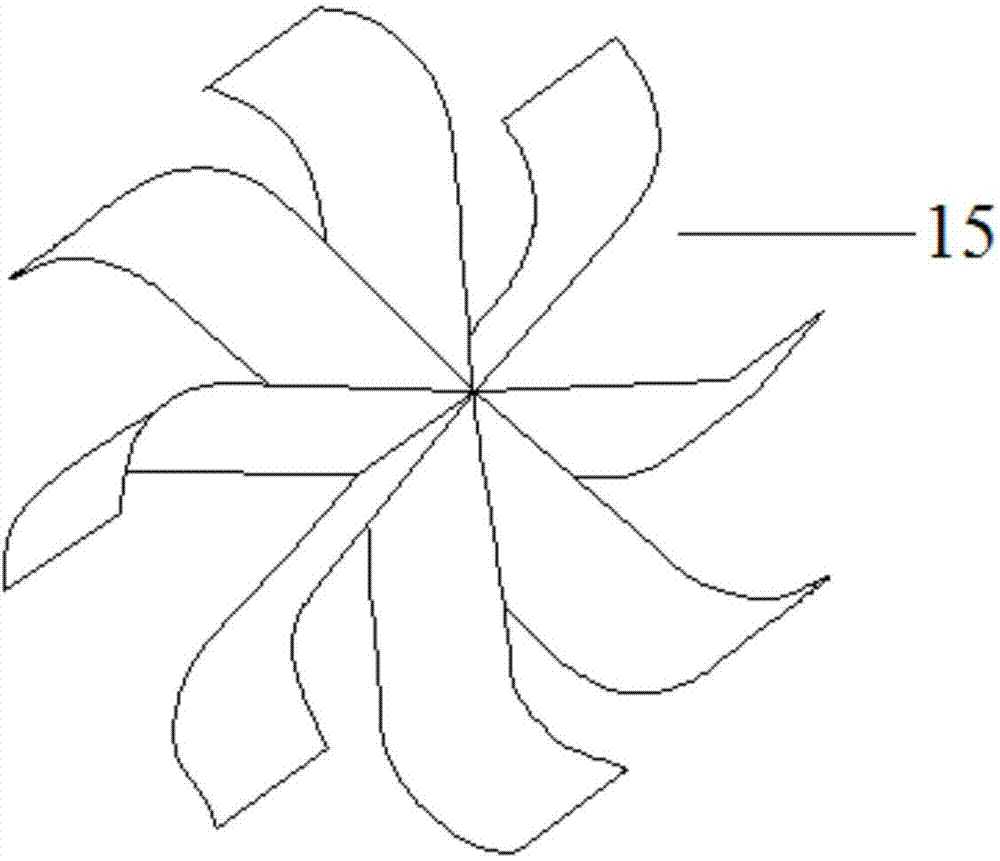

[0036] The straight-shaped gradient stacked porous media burner includes a shell, and a gas inlet 1, a premixing chamber 3, an axial heat insulation layer, an igniter lead wire protection tube 2, and an igniter 6 are arranged sequentially in the shell from top to bottom. , Gradient ceramic porous medium layer 7, catalytic layer 12. The filled porous medium heater consists of an external insulation layer, a metal mesh cylinder arranged in the insulation layer, and heating tubes 14 arranged symmetrically in the center of the metal mesh cylinder, and metal wires 13 are filled in the gaps of the heating tubes 14 .

[0037] Specifically, filling the pre-mixing chamber 3 with a filamentous porous medium material can form a turbulent flow on the one hand to mix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com