Antibacterial, moisture absorption and sweat releasing polyester composite elastic fiber

A composite elastic fiber, moisture wicking technology, applied in fiber processing, conjugated synthetic polymer man-made filament, filament/thread forming and other directions, can solve the problem of single function of elastic fiber, etc., and achieve simple and functional weaving process. outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

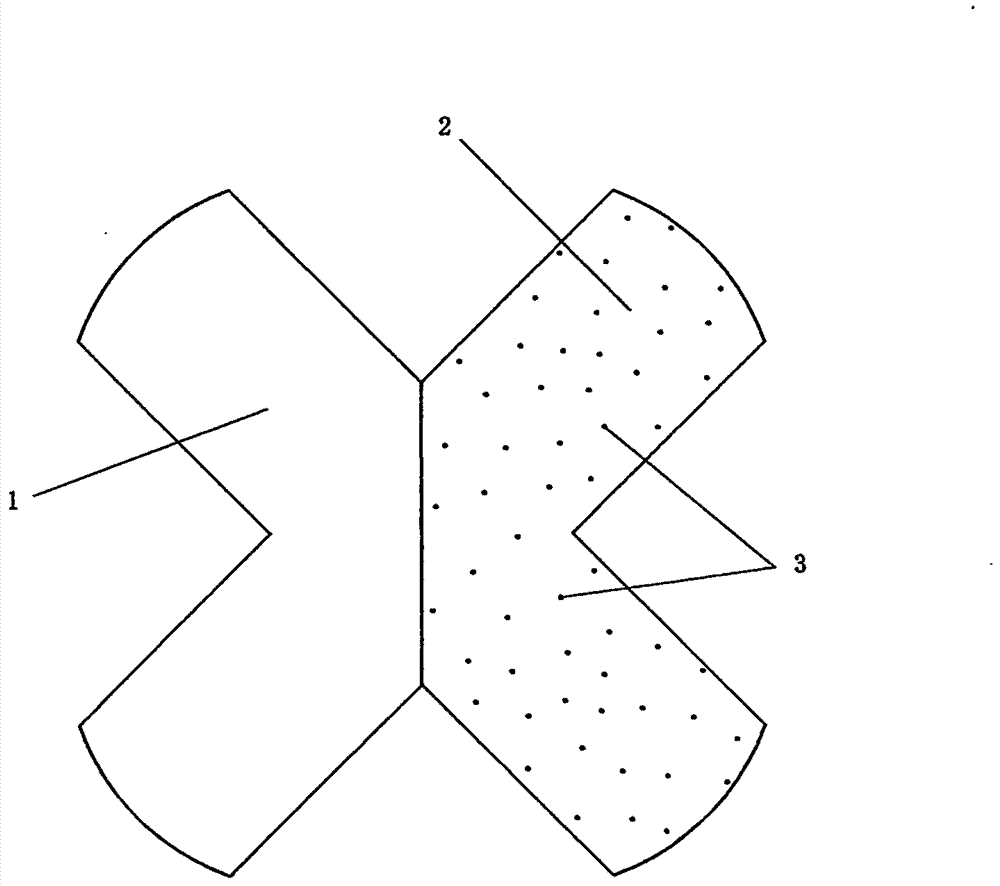

Embodiment 1

[0023] Preparation of PTT / PET composite elastic staple fiber with antibacterial moisture absorption and perspiration: slice and dry PTT and hydrophilic modified PET polyester raw materials, add silver ion antibacterial agent masterbatch to PTT component after drying, and blend the two components Separately input into the two screw extruders of the parallel composite spinning equipment, the metering pumps are respectively metered and then input into the spinning box, and melted and extruded through the specific spinneret assembly with the spinneret hole as a "symmetrical double right angle" structure. , air blowing and cooling, the tow is wound and dropped into the barrel, clustered, then wound after primary drafting and secondary drafting, cut and packed after heat setting, and hydrophilic PTT / PET composite elastic staple fiber is obtained. The composite fiber has a cross-section structure, the mass ratio of PTT and PET is 50:50, and the content of silver ion antibacterial agen...

Embodiment 2

[0025] Preparation of PBT / PET composite elastic filaments with antibacterial moisture absorption and perspiration: PBT and hydrophilic modified PET polyester raw materials are sliced and dried, and the silver ion antibacterial agent masterbatch is dried and added to the hydrophilic modified PET component for blending. The two components are respectively input into the two screw extruders of the parallel composite spinning equipment, and the metering pumps are respectively metered and then input into the spinning box, and the spinneret hole is a special spinneret with a "symmetrical double right angle" structure. The components are melted and extruded, blown and cooled, oiled and integrated into tows, and the tows are drawn, wound, and heat-set to produce hydrophilic PBT / PET composite elastic filaments. The composite fiber has a cross-section structure, the mass ratio of PBT and PET is 50:50, and the content of silver ion antibacterial agent is 1.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com