Abrasion-resistant seamless steel pipe for conveying and production method of abrasion-resistant seamless steel pipe for conveying

A technology of a seamless steel pipe and a production method, which is applied to the production of seamless steel pipes in the metallurgical industry, can solve the problems of unsatisfactory strength and toughness coordination, complex manufacturing process, low low temperature toughness, etc., and can solve the problems of low low temperature impact toughness and fine grain chemical resistance, good wear resistance and low temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

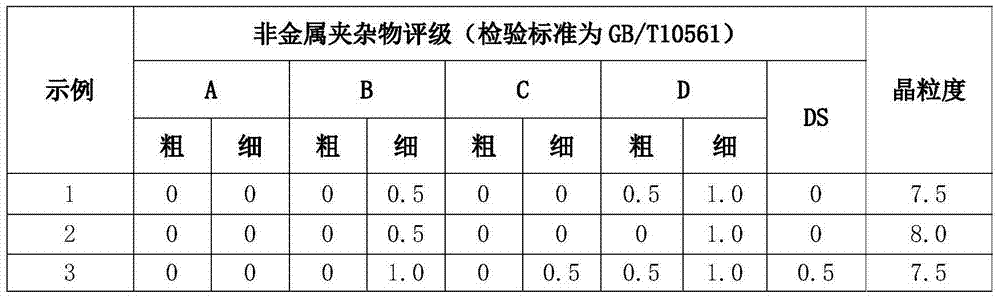

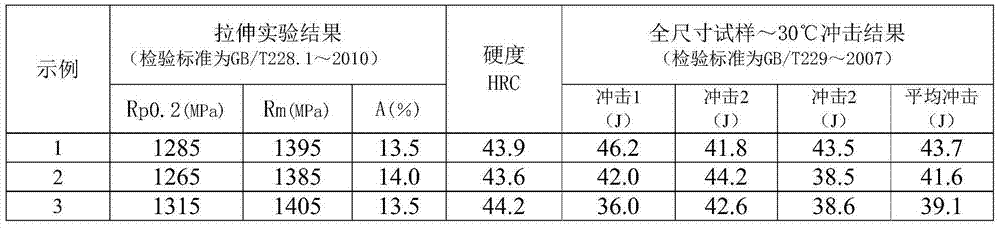

[0019] Hereinafter, a wear-resistant seamless steel pipe for transportation and a production method thereof of the present invention will be described in detail with reference to exemplary embodiments.

[0020] The production method of the wear-resistant seamless steel pipe for transportation according to one aspect of the present invention includes the steps of:

[0021] a. Smelting tube blanks, the chemical composition of the tube blanks is C 0.28-0.36%, Si 0.70-1.30%, Mn 2.80-3.20%, V 0.05-0.15%, Nb 0.02-0.04%, Cr 0.40% by weight ~0.80%, Mo 0.14~0.26%, B 0.0005~0.0035%, As 0~0.015%, Sn 0~0.010%, P 0~0.015%, S 0~0.010% and the balance of Fe;

[0022] b. Rolling the billet into a seamless steel pipe, the heating temperature of the billet before rolling is 1220-1260°C, and the final rolling temperature is controlled at 860-900°C.

[0023] c. Carry out heat treatment for the produced seamless steel pipe, including quenching and tempering, the quenching heating temperature is 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com