A sewage treatment system and method for reducing greenhouse gas emissions

A sewage treatment system and greenhouse gas technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems that are not conducive to economic and environmental development, increase the greenhouse effect, and waste Energy and other issues to achieve the effect of reducing the loss of sludge, slowing down the greenhouse effect, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

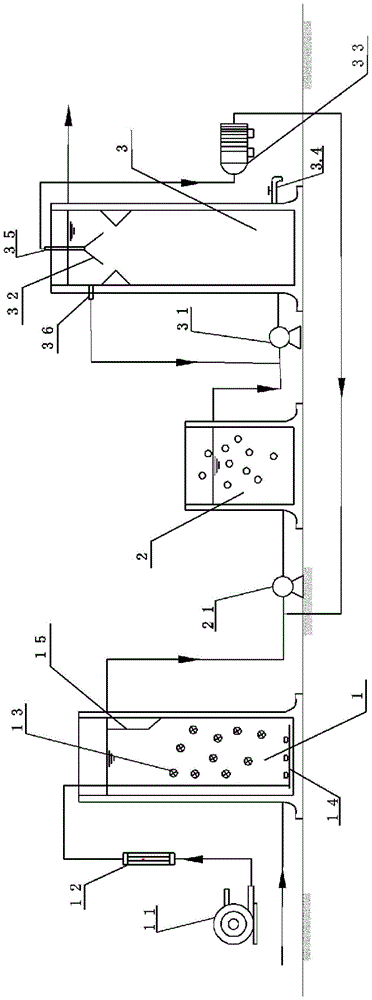

Image

Examples

Embodiment 1

[0031] Using the above device, the specific operation method is as follows:

[0032] 1) Inoculate the cultivated and domesticated short-range nitrification sludge into MBBR, and the sludge concentration MLSS after dosing is 30-35g / L; The sludge concentration MLSS is 10-15g / L;

[0033] 2) The sewage enters the MBBR after adjusting the water volume and uniform water quality, and the air blower and air flow meter adjust the flow to provide the oxygen needed by the ammonia-oxidizing bacteria inoculated in the MBBR and to circulate the filler in the reactor to achieve NO 2 - accumulation. The operating temperature of MBBR is controlled at 20-25°C, the operating pH is 6.5-8.5, the hydraulic retention time HRT is 16-20h, the sludge age is controlled at 1.0-1.5d, and the dissolved oxygen DO is controlled at 0.5-1.0mg / L;

[0034] 3) The effluent of MBBR is introduced into the stripping tank through a peristaltic pump to remove dissolved oxygen in the water;

[0035] 4) Then enter t...

Embodiment 2

[0037] Using the above device, the specific operation method is as follows:

[0038] 1) Inoculate the cultivated and domesticated short-range nitrification sludge into MBBR, and the sludge concentration MLSS after dosing is 35-40g / L; The sludge concentration MLSS is 15-20g / L;

[0039] 2) The sewage enters the MBBR after adjusting the water volume and uniform water quality, and the air blower and air flow meter adjust the flow to provide the oxygen needed by the ammonia-oxidizing bacteria inoculated in the MBBR and to circulate the filler in the reactor to achieve NO 2 - accumulation. The operating temperature of MBBR is controlled at 25-28°C, the operating pH is 6.5-8.5, the hydraulic retention time HRT is 20-24h, the sludge age is controlled at 2.0-2.5d, and the dissolved oxygen DO is controlled at 1.0-1.5mg / L;

[0040] 3) The effluent of MBBR is introduced into the stripping tank through a peristaltic pump to remove dissolved oxygen in the water;

[0041] 4) Then enter t...

Embodiment 3

[0043]Use the above-mentioned sewage treatment system to reduce greenhouse gas emissions to treat domestic sewage in a certain area. The water quality characteristics of sewage are: low COD, 120-266mg / L, BOD 5 13-48mg / L, BOD 5 The / COD is 0.19-0.4, the ammonia nitrogen content is relatively high, 32-45mg / L, and the highest sustainable value is 60mg / L. The sludge concentration in MBBR is maintained at 35-40g / L, and the sludge concentration in UASB is maintained at 15-20g / L. NO 2 - The accumulation is then utilized by denitrifying anaerobic methane oxidizing bacteria, and finally realizes the denitrification and carbon removal of sewage. The final effluent index COD is within 50mg / L, the effluent ammonia nitrogen is within 5mg / L, and the N 2 O emission is reduced by 61.5% compared with traditional treatment processes, and there is no methane gas emission, which has good denitrification and carbon removal effects and reduces greenhouse gas emissions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com