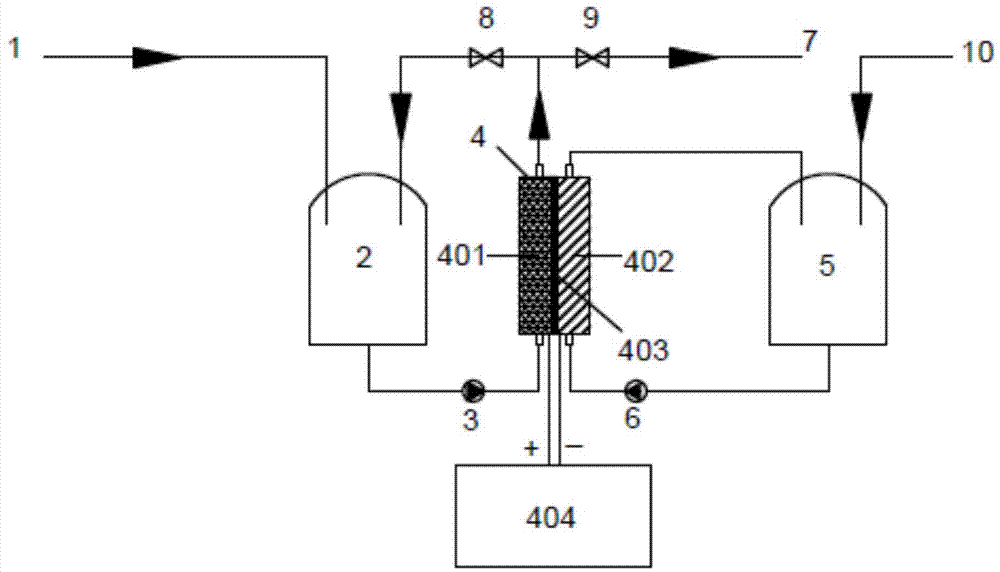

Electrochemical treatment system and electrochemical treatment method for treating nickel-containing wastewater

A treatment system, electrochemical technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of cathode current efficiency drop, cumbersome follow-up process, clogging of ion exchange membrane or ion exchange Resin and other problems, to achieve the effects of improved nickel recovery, simple process flow, and high current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

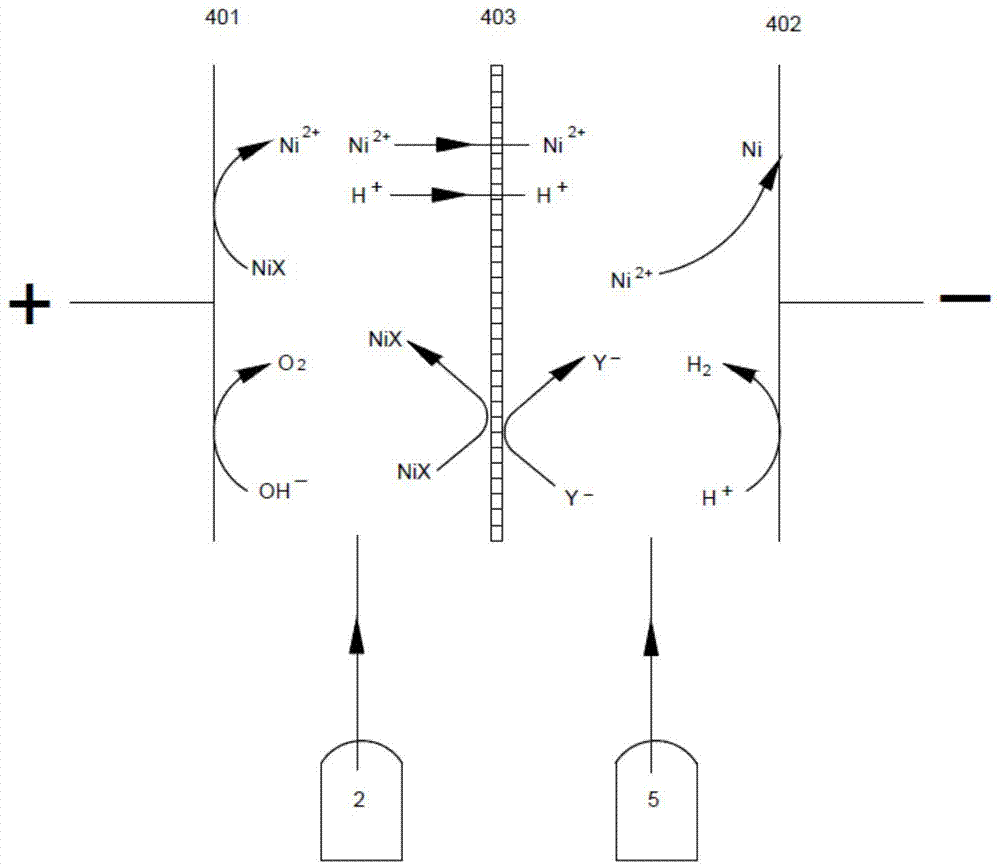

Method used

Image

Examples

Embodiment 1

[0027] Put 1L nickel-containing waste water (concentration of ionic nickel is 100mg / L, total nickel concentration is 120mg / L, COD value is 56mg / L, adjust pH=4 with sulfuric acid) into the electrolysis water inlet tank 2, and simultaneously put the concentration of 1L It is 20g / L nickel sulfate solution, adjust pH=4 with sulfuric acid and put it into the catholyte circulating water tank, close the drain valve 9, open the backflow water valve 8, and the shape stable anode of the diaphragm electrolysis reactor 4 adopts a titanium-based ruthenium oxide iridium electrode , the anode area is 15cm*15cm, the cation exchange membrane adopts the CMB positive membrane of Japan ASTOM company, the cathode is a stainless steel electrode, the area is 15cm*15cm, turn on the cathode and anode circulation pumps 3 and 6, turn on the DC power supply 404 switch, and adjust the voltage to 5.0 V, after 20 hours of electrolysis, the concentration of free nickel ions in the electrolyte in the anode are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com