Support transport vehicle with double engines

A support truck and dual-engine technology, applied in the direction of power plant, vehicle parts, transportation and packaging, etc., can solve the problems of increased operation difficulty, short continuous working time, insufficient power, etc., achieve compact structure, increase the volume of diesel tank, Achieving Power and Traction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

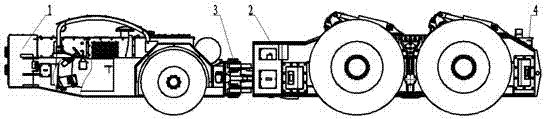

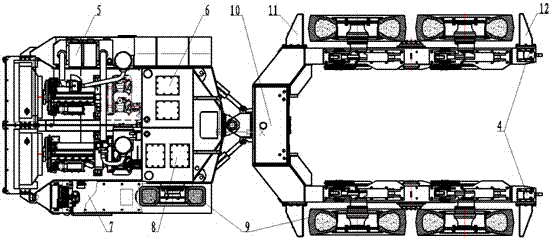

[0023] Such as figure 1 , figure 2 As shown, a dual-engine support truck, including:

[0024] Front frame 1: Exhaust gas treatment tank 5, water replenishment tank 6, driver's cab 7, diesel tank 8 and power drive system 9 are installed on the front frame;

[0025] U-shaped frame 2: The U-shaped frame 2 is equipped with a hydraulic oil tank 10 installed at the head of the U-shaped frame, an anti-collision block 11 installed at the front of the U-shaped frame tire, and an anti-collision block 11 installed at the rear of the U-shaped frame tire. Collision block 12, reversing image 4 and power drive system 9;

[0026] Pin shaft 3: the shaft pin 3 connects the front frame 1 and the U-shaped frame 2;

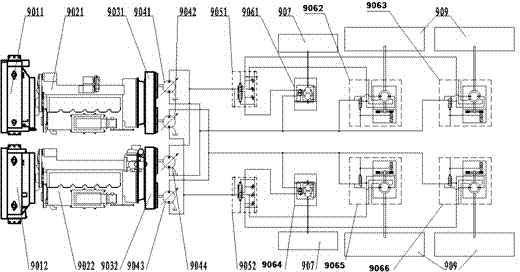

[0027] Such as image 3 , Figure 4 , Figure 5 As shown, the power drive system: The power drive system includes a power part and a drive part, and the power part includes two explosion-proof engines and two radiators for cooling the two explosion-proof engines respectively, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com