Computer-to-plate flexible plate and production method thereof

A technology of computer and flexographic plate, which is applied in the field of flexible photosensitive resin plate and its preparation, can solve the problems of slow ablation speed, shorten plate making time, troublesome ablation residue treatment, etc., and achieve good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

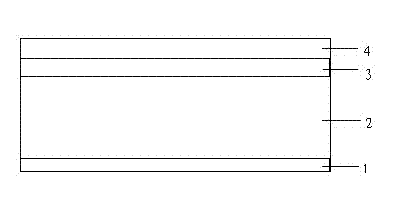

[0035] The support (1) can be selected from polyhexylene naphthalene-2,6-dicarbonate, polyethylene terephthalate, polybutylene terephthalate, etc., with a thickness of 50-300 μm. In this embodiment, polyethylene terephthalate is used as a support body with a thickness of 100 μm, produced by Lucky Company.

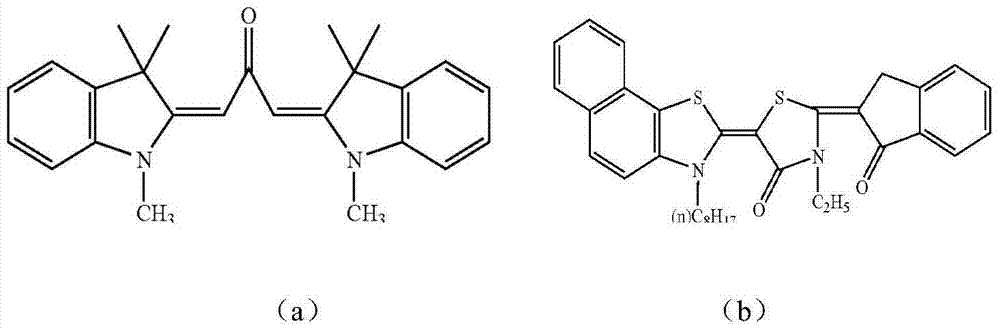

[0036] Preparation of the photosensitive elastomer layer (2): 700 g of thermoplastic elastomer SIS1107 (Kraton Company), 200 g of plasticizer polybutadiene NissoPB-P2000 (NipponSoda, Japan), 1-hydroxycyclohexyl phenyl ketone (Zhangjiagang) Free Trade Zone Tianjie International Trade Co., Ltd.) 32g, 2,6-ditert-butyl-p-cresol (Nanjing Jiulong Chemical Co., Ltd.) 12g, trimethylolpropane triacrylate 40g (Tianjin Tianjiao Chemical Co., Ltd.), 1,9 - 15.8g of nonanediol diacrylate (Tianjin Tianjiao Chemical Co., Ltd.), 0.2g of dye RED335 (BASF company), 0.2g of styrylbenzimidazole dye, join in the twin-screw extruder, and mix at 150°C for 2 minutes, extrude a photosensitive elast...

Embodiment 2

[0043] The support (1) can be selected from polyhexylene naphthalene-2,6-dicarbonate, polyethylene terephthalate, polybutylene terephthalate, etc., with a thickness of 50-300 μm. In this embodiment, polyethylene terephthalate is used as a support body with a thickness of 125 μm, produced by Lucky Company.

[0044] Preparation of the photosensitive elastomer layer (2): 700 g of thermoplastic elastomer SISD1160ES (Kraton Company), 200 g of plasticizer polybutadiene NissoPB-P2000 (NipponSoda, Japan), 1-hydroxycyclohexyl phenyl ketone (Zhangjiagang) Free Trade Zone Tianjie International Trade Co., Ltd.) 32g, 2,6-ditert-butyl-p-cresol (Nanjing Jiulong Chemical Co., Ltd.) 12g, trimethylolpropane triacrylate 40g (Tianjin Tianjiao Chemical Co., Ltd.), 1,9 - 15.8g of nonanediol diacrylate (Tianjin Tianjiao Chemical Co., Ltd.), 0.2g of dye RED335 (BASF Company), 0.2g of pyridinium cyanine dye, added to the twin-screw extruder, mixed for 2 minutes at 140°C, and extruded A photosensitive...

Embodiment 3

[0049] The selection of the support (1) is the same as in Example 2.

[0050] Preparation of the photosensitive elastomer layer (2): 750 g of thermoplastic elastomer SIS1107 (Kraton Company), 150 g of plasticizer polybutadiene NissoPB-P2000 (NipponSoda, Japan), 1-hydroxycyclohexyl phenyl ketone (Zhangjiagang) Free Trade Zone Tianjie International Trade Co., Ltd.) 32g, 2,6-ditert-butyl-p-cresol (Nanjing Jiulong Chemical Co., Ltd.) 12g, trimethylolpropane triacrylate 30g (Tianjin Tianjiao Chemical Co., Ltd.), 1,9 - 25.8g of nonanediol diacrylate (Tianjin Tianjiao Chemical Co., Ltd.), 0.2g of dye RED335 (BASF Company), 0.2g of copper phthalocyanine, added to the twin-screw extruder, mixed for 2 minutes at 140°C, and extruded A photosensitive elastomer layer (2) with a thickness of 2.70mm, set aside.

[0051] The anti-adhesive layer (3) was prepared the same as in Example 1.

[0052] The protective film (4) is selected from the same embodiment 1.

[0053] The lower surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com