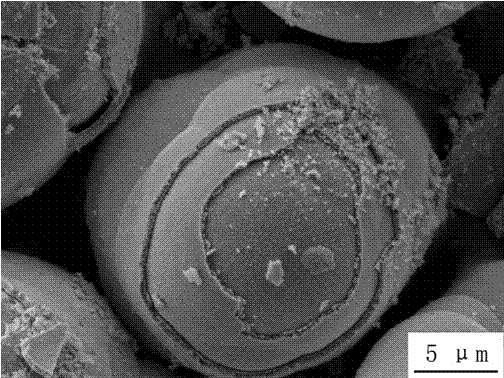

Preparation method of lithium ion batteries cathode material solid solution with core-shell structure

A positive electrode material and core-shell structure technology, which is applied in the field of preparation of solid solution of positive electrode material for core-shell structure lithium ion batteries, can solve the problems of limited application, poor rate performance, poor conductivity, etc., achieve high rate performance, and improve volume specific energy. , the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Solid solution Li 1.2 [(Mn 1 / 3 Ni 1 / 3 co 1 / 3 ) 0.5 (Ni 1 / 4 mn 3 / 4 ) 0.5 ] 0.8 o 2 The preparation process

[0017] (1) Weigh the required MnSO according to the stoichiometric ratio of 1:1:1 4 、NiSO 4 Salt and CoSO 4 Dissolve the salt in deionized water to prepare a 300ml solution with a concentration of 1.5mol / L.

[0018] (2) Prepare 300ml of sodium carbonate solution with the same concentration as the above-mentioned total metal ions, add ammonia water as complexing agent, and the concentration of ammonia water is 0.2 mol / L.

[0019] (3) Use a peristaltic pump to continuously input the metal salt solution and sodium carbonate solution into the reaction flask, control the flow rate to 5ml / min, the temperature of the water bath in the reactor is in the range of 55 °C, control the pH of the slurry to 8, and control the stirring speed at 600 rpm .

[0020] (4) After stirring for 3 hours, the NiSO 4 with MnSO 4 According to the molar ratio of stoichiometric ...

Embodiment 2

[0026] Solid solution Li 1.1 [(Mn 1 / 3 Ni 1 / 3co 1 / 3 ) 0.5 (Ni 1 / 4 mn 3 / 4 ) 0.5 ] 0.9 o 2 The preparation process

[0027] (1)-(7) Same as Example 3

[0028] (8) Mix the precursor with Li at a molar ratio of 1.1:0.45 2 CO 3 Mix the powder evenly and roast in the air atmosphere. Pre-calcined at 400–600 °C for 5 h, and then roasted at 800–1000 °C for 10 h with a heating rate of 5 °C / min.

[0029]

Embodiment 3

[0031] Solid solution Li 1.2 [(Mn 1 / 3 Ni 1 / 3 co 1 / 3 ) 0.7 (Ni 1 / 4 mn 3 / 4 ) 0.3 ] 0.8 o 2 The preparation process

[0032] (1) Weigh the required Mn(NO 3 ) 2 , Ni(NO 3 ) 2 Salt and Co(NO 3 ) 2 The salt was dissolved in deionized water to prepare 400ml of a solution with a concentration of 1.4mol / L.

[0033] (2) Prepare 400ml of sodium carbonate solution with the same concentration as the above-mentioned total metal ions, add ammonia water as complexing agent, and the concentration of ammonia water is 0.2 mol / L.

[0034] (3) Use a peristaltic pump to continuously input the metal salt solution and sodium carbonate solution into the reaction flask, control the flow rate to 5ml / min, the temperature of the water bath in the reactor is in the range of 55 °C, control the pH of the slurry to 8, and control the stirring speed at 600 rpm .

[0035] (4) After stirring for 3 hours, the Ni(NO 3 ) 2 with Mn(NO 3 ) 2 According to the molar ratio of stoichiometric ratio 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com