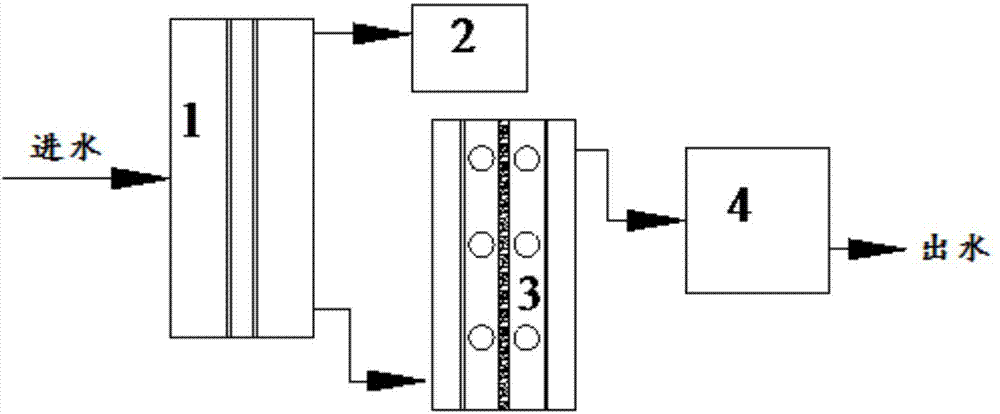

Photoelectrocatalysis/Fenton coupling processing system and processing method of high-salt polymer-containing wastewater

A photoelectric catalysis and treatment system technology, which is applied in water/sewage treatment, mining wastewater treatment, light water/sewage treatment, etc., can solve the problem of limited contact area between catalysts and pollutants, achieve reduced energy consumption, mild reaction conditions, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

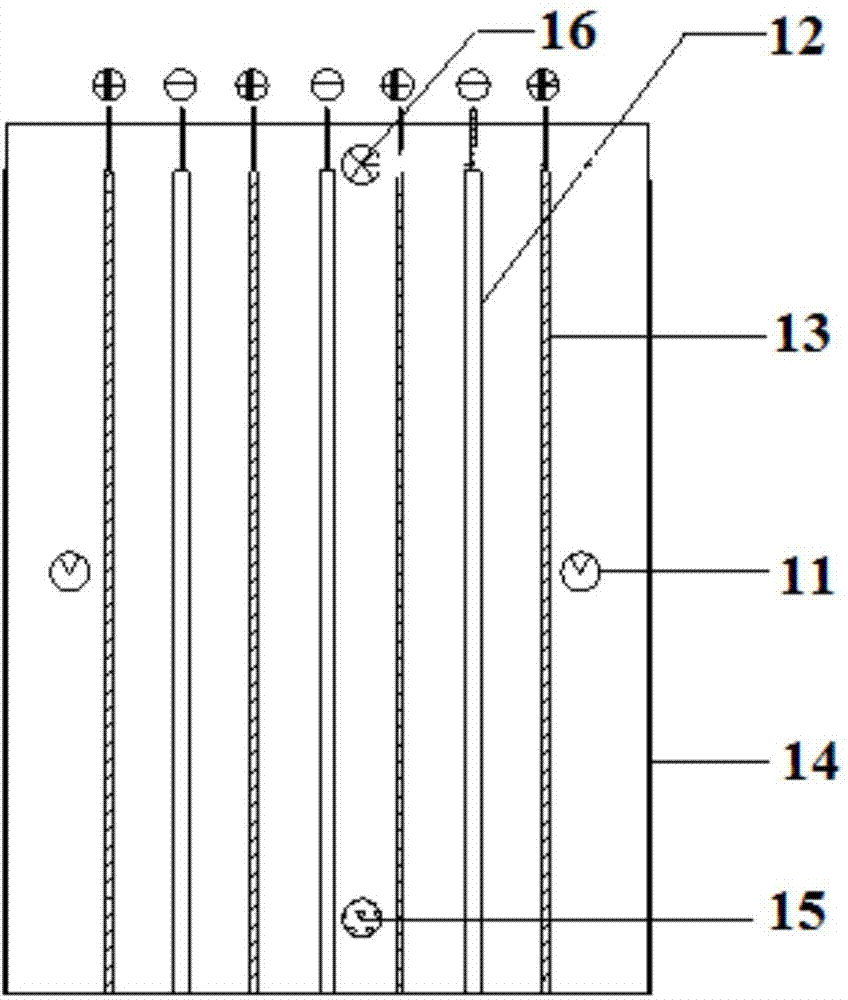

[0040] This embodiment is an application embodiment of the device and method of the present invention for actually treating wastewater. The biochemical effluent of oil production wastewater from an oil production plant in Liaoning has a chloride ion concentration of 4000-5000mg / L, a conductivity of about 11000μs / cm, COD250-350mg / L, and petroleum 20-30mg / L. High salt has a strong inhibitory effect on biochemical effects, and the biochemical effluent does not meet the standard. The advanced treatment test of biochemical effluent was carried out by using electrolysis-photoelectrocatalysis / Fenton coupling wastewater treatment device. Current density 15mA / cm 2 , residence time 10min, current density 5mA / cm 2 , air velocity 18m 3 / h, residence time 30min, effluent COD<50mg / L, petroleum <3mg / L, meeting water quality discharge requirements.

[0041] water sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com