Multifunctional integrated intaglio printing press and machining process thereof

A kind of gravure printing machine and multi-functional technology, which is applied in the field of multi-functional integrated gravure printing machine and its processing technology, can solve the problems of difficult to meet control requirements, waste of time, etc., achieve consistent line speed, save material area, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

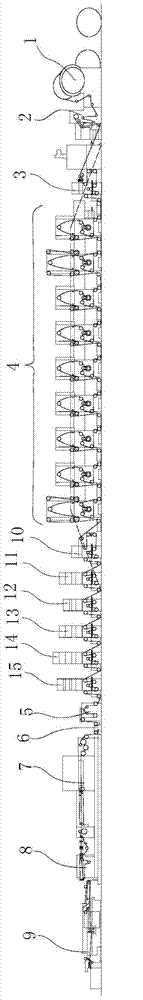

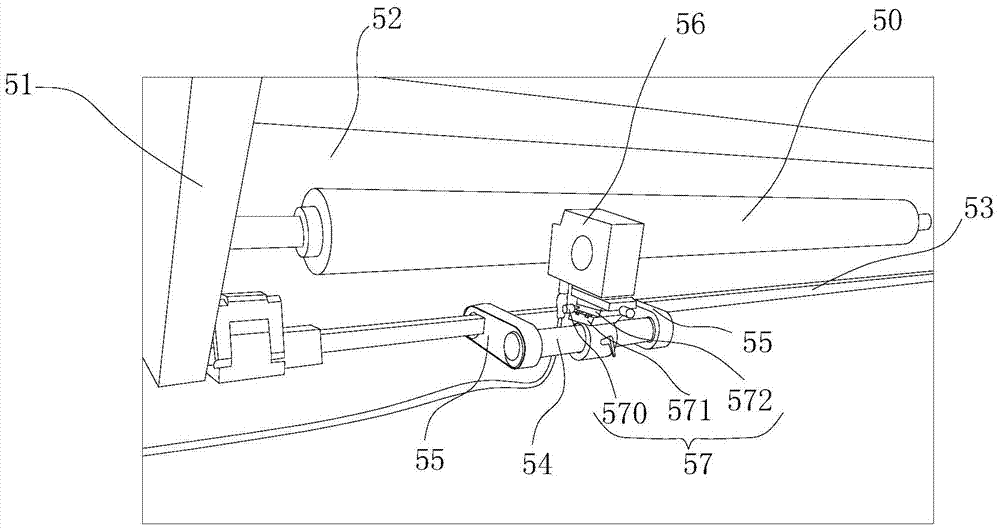

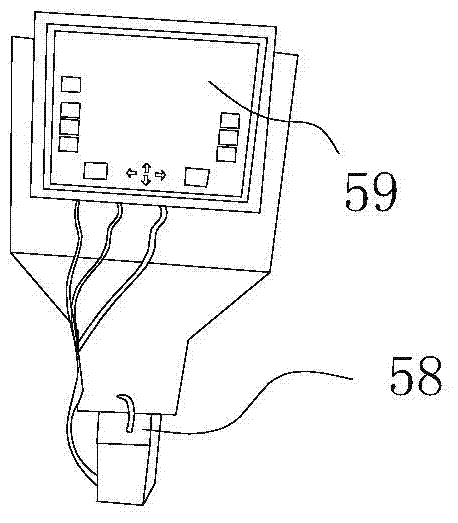

[0042] Multifunctional gravure printing machine, such as figure 1 As shown, it includes the unwinding and unwinding device 1, the introduction and correction device 2, the double traction device 3, the printing unit 4, the trimming device 5, the embossing device 6, and the die-cutting device arranged in a straight line from the automatic input of the paper roll to the automatic output of the finished product. Device 7, soft label cutting device 8 and automatic stacking paper receiving device 9, introduce deviation correcting device 2 to pull the paper output from unwinding and unwinding device 1, and then send it to double traction device 3; Both sides are cut with raw edges respectively, embossing device 6 carries out indentation processing on cigarette label printing paper, die-cutting device 7 carries out shape cutting or cutting processing on cigarette label printing paper, soft label cutting device 8 carries out cigarette label printing paper High-precision cutting and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com