Preparation method of cadmium removal agent of thiolated chitosan microsphere

A chitosan microsphere, chitosan technology, applied in chemical instruments and methods, water/sludge/sewage treatment, adsorbed water/sewage treatment, etc., can solve the loss of chitosan of adsorbent, loss of adsorbent It can improve the adsorption performance, improve the selective adsorption and improve the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

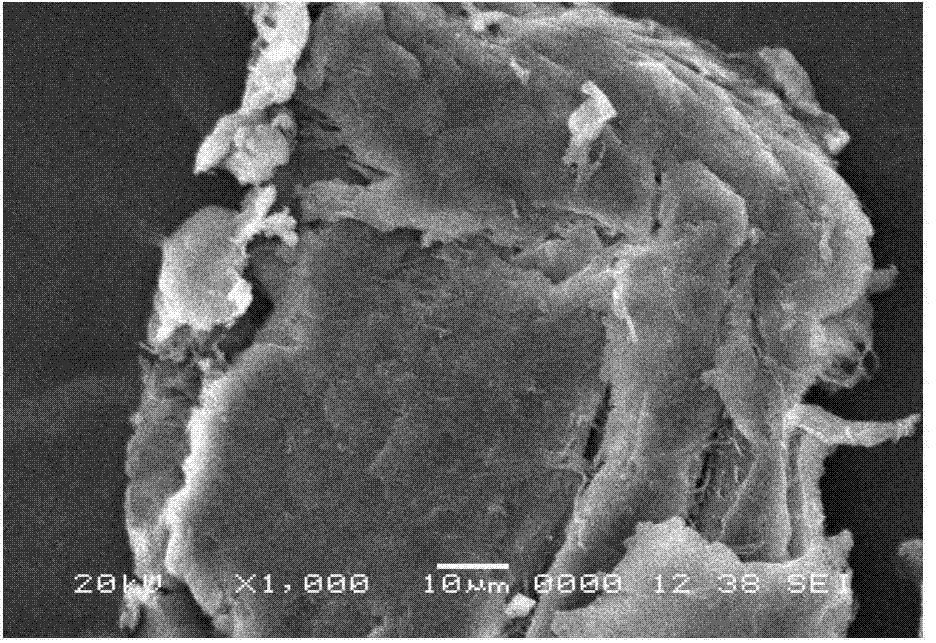

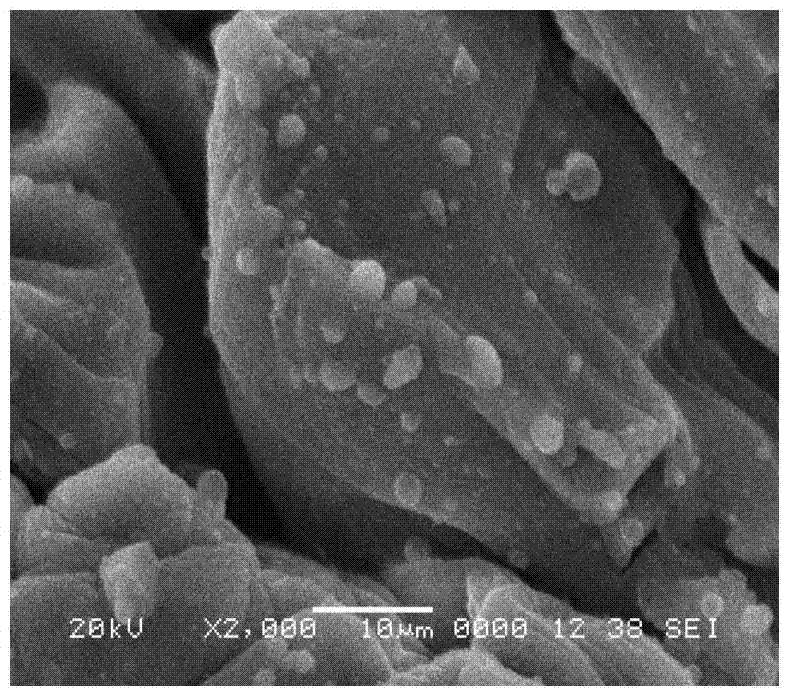

Image

Examples

Embodiment 1

[0021] (1) Dissolve 3g chitosan in 200ml 5wt% acetic acid solution, add 1.5g cadmium chloride, magnetically stir for 3h, add 20wt% sodium hydroxide solution dropwise, form gel until maximum amount, filter, wash, Dried to obtain cadmium ion imprinted chitosan;

[0022] (2) Dissolve 3g of cadmium ion imprinted chitosan in 900ml 5wt% acetic acid solution, adjust to pH 6 with 20wt% sodium hydroxide solution, add 100ml 1wt% tripolyphosphate drop by drop, after magnetic stirring for 2h , then adjust the pH to 13 with 20wt% sodium hydroxide solution to form a red gel, filter, wash, and dry to obtain cross-linked chitosan;

[0023] (3) After the cross-linked chitosan is eluted with 0.1M hydrochloric acid until no cadmium ion is detected, it is washed with deionized water until neutral, and dried to obtain chitosan microspheres;

[0024] (4) Add 3g of chitosan microspheres into 300ml of 20wt% sodium hydroxide solution, alkalinize for 1 hour, add 2ml of carbon disulfide, stir magnetica...

Embodiment 2

[0026] (1) Dissolve 5g chitosan in 300ml 5wt% acetic acid solution, add 2.5g cadmium nitrate, magnetically stir for 3h, add 20wt% sodium hydroxide solution dropwise, form gel until the maximum amount, filter, wash, dry , to obtain cadmium ion imprinted chitosan;

[0027] (2) 5g cadmium ion imprinted chitosan was dissolved in 1500ml 5wt% acetic acid solution, adjusted to pH 6 with 20wt% sodium hydroxide solution, and 200ml 1wt% tripolyphosphate was added dropwise, after magnetic stirring for 2h , then adjust the pH to 13 with 20wt% sodium hydroxide solution to form a red gel, filter, wash, and dry to obtain cross-linked chitosan;

[0028] (3) After the cross-linked chitosan is eluted with 0.1M hydrochloric acid until no cadmium ion is detected, it is washed with deionized water until neutral, and dried to obtain chitosan microspheres;

[0029] (4) Add 5g of chitosan microspheres into 500ml of 20wt% sodium hydroxide solution, alkalinize for 1 hour, add 2ml of carbon disulfide, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com