Feed method preventing crash onto spindle of horizontal five-axis machine at swinging angle A/B

A machine tool spindle, five-coordinate technology, used in computer control, instruments, simulators, etc., can solve problems such as tool or spindle collision with parts or tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

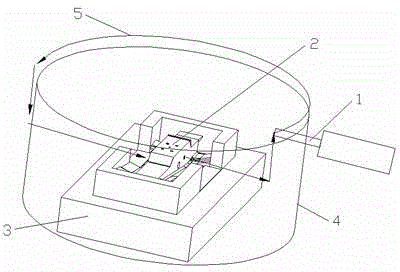

[0006] figure 1 It is a schematic diagram of the tool-moving method for preventing the spindle collision of A and B swing angle horizontal five-coordinate machine tool spindles of the present invention. The tool-moving method for preventing the collision of A and B swing angle horizontal five-coordinate machine tool spindles of the present invention comprises the following steps: Establish a tool path auxiliary body 4, the tool path auxiliary body 4 is a cylinder, and the cylinder is coated on the part 2 and the tooling 3 for installing the part; after the tool 1 is processed at a certain station, The tool tip of tool 1 retracts to the outer cylindrical surface of tool path auxiliary body 4, and then the tool tip of tool 1 is raised to the top surface of the outer cylinder, and then the tool tip of tool 1 moves along the outer circle of the top surface of the outer cylinder, and the center of the top surface of the outer cylinder Rotate at angle B; the tip of tool 1 rotates to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com