A dc1500v collector device for trolleybus

A DC1500V, trolley bus technology, applied in collectors, power collectors, electric vehicles, etc., can solve problems such as easy off-line, large up and down vibration amplitude, irregularity, etc., to improve operational reliability, simple structure, and structure novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

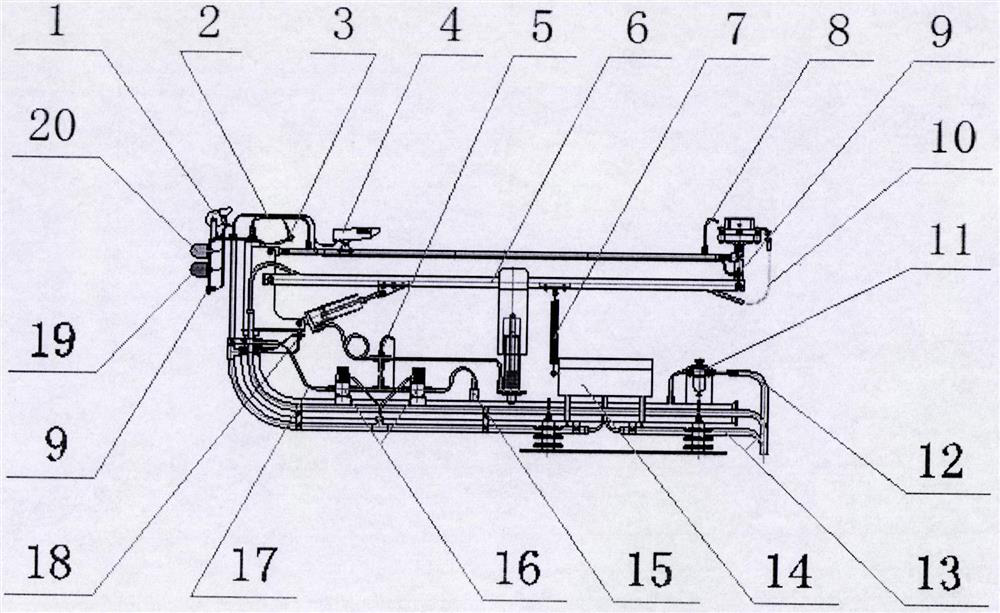

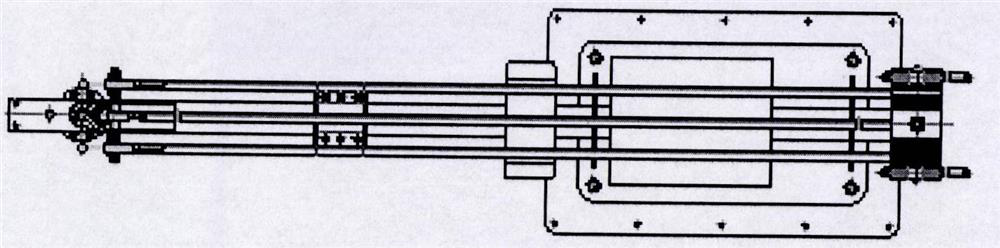

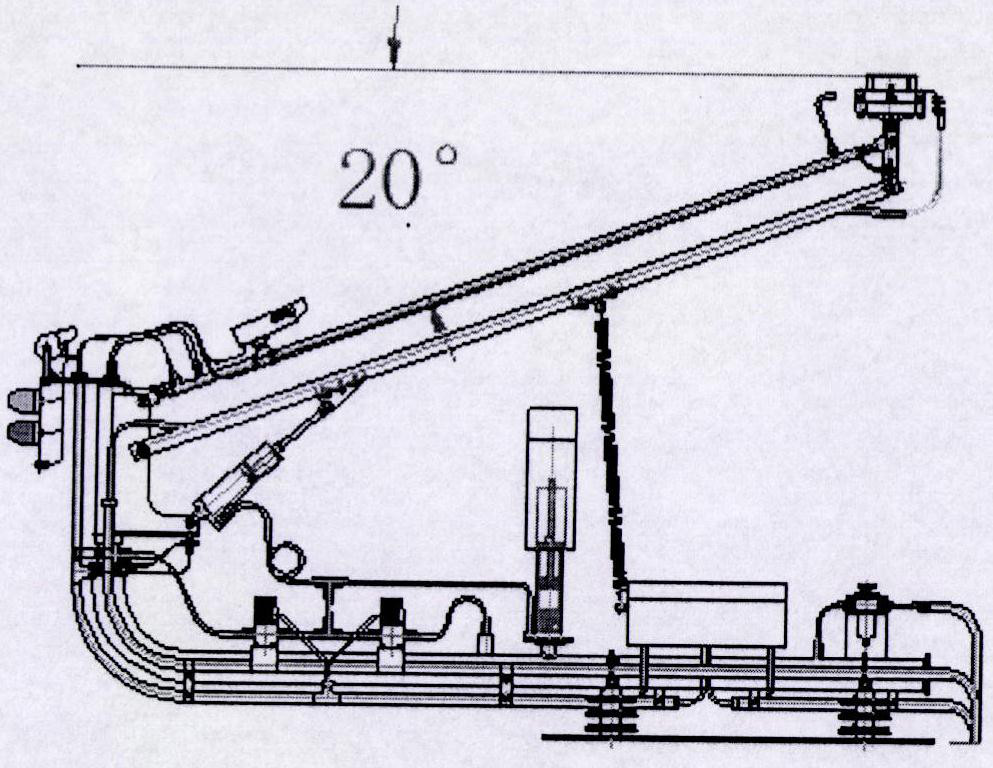

[0023] see Figure 1-8 , a trolleybus DC1500V collector device, including a trolleybus collector body, the trolleybus collector body is composed of a top lighting lamp 1, a cable 2, a power sensor 3, a camera 4, a pressure sensor 5, and a parallelogram wrist arm Combination 6, return spring 7, dust removal air pipe 8, front and rear distance radar 9, cable soft protection pipe 10, air pressure regulating valve 11, main air pipe 12, cable protection pipe 13, control distribution box 14, one-way valve 15, lifting electromagnetic Valve 16, high-pressure hose 17, cantilever angle control sensor 18, power receiving indicator light 19 and bow-off warning light 20; the main structure of the trolleybus collector body is a parallelogram wrist-arm combination with a V-shaped power receiving device Erected on the pneumatic device, the main structure is simpl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com