Gel-like polymer electrolyte and method for preparing solid-state electrochromic devices based on conductive polymers

A conductive polymer, polymer technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problem that there is no large-scale production of PEC materials and their solid devices, the preparation technology of PEC materials is not mature enough, and there is no large-scale industrial application and other issues, to achieve the effect of good processing performance, easy preparation and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

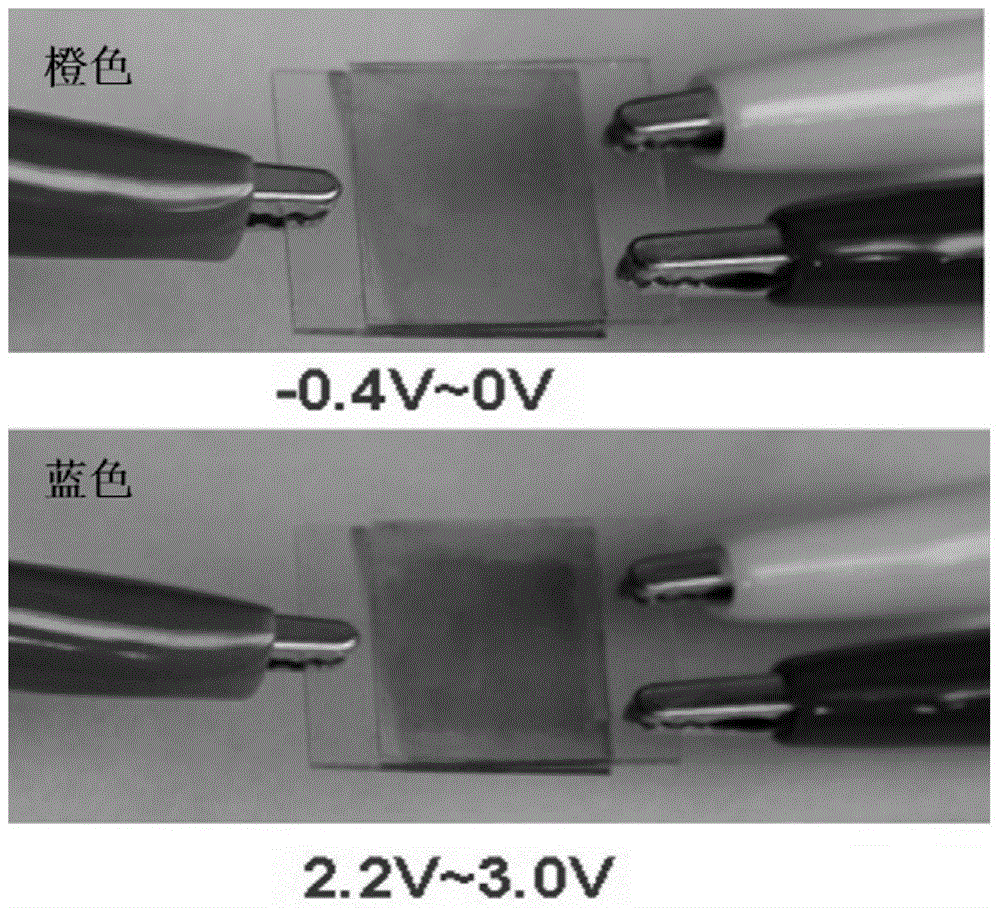

[0039] A method for preparing a single-layer solid device based on a conductive polymer electrochromic material, comprising the following steps:

[0040] Step (1) prepares gel-like polymer electrolyte:

[0041] According to the mass ratio of electrolyte substances to CH 3 CN: PC: PMMA: LiClO 4 =70:20:7:3 Weigh the raw materials, wherein propylene carbonate (PC) (1g), chemically pure; polymethyl methacrylate (PMMA) (0.35g), requires a weight average molecular weight of (MW=120000g / mol), chemically pure; acetonitrile (ACN) (3.5g), chromatographically pure; lithium perchlorate (LiClO 4 ) (0.15g), analytically pure. Put the weighed PMMA and PC into a round-bottomed flask (50ml) with a hollow stopper, and put them in an oven at a constant temperature of 70°C for 18h to make the PMMA well swell in the PC. Add the supporting electrolyte lithium perchlorate (0.15g) and the electrolytic solvent acetonitrile (3.5g) prepared according to the mass ratio into the round bottom flask, a...

Embodiment 2

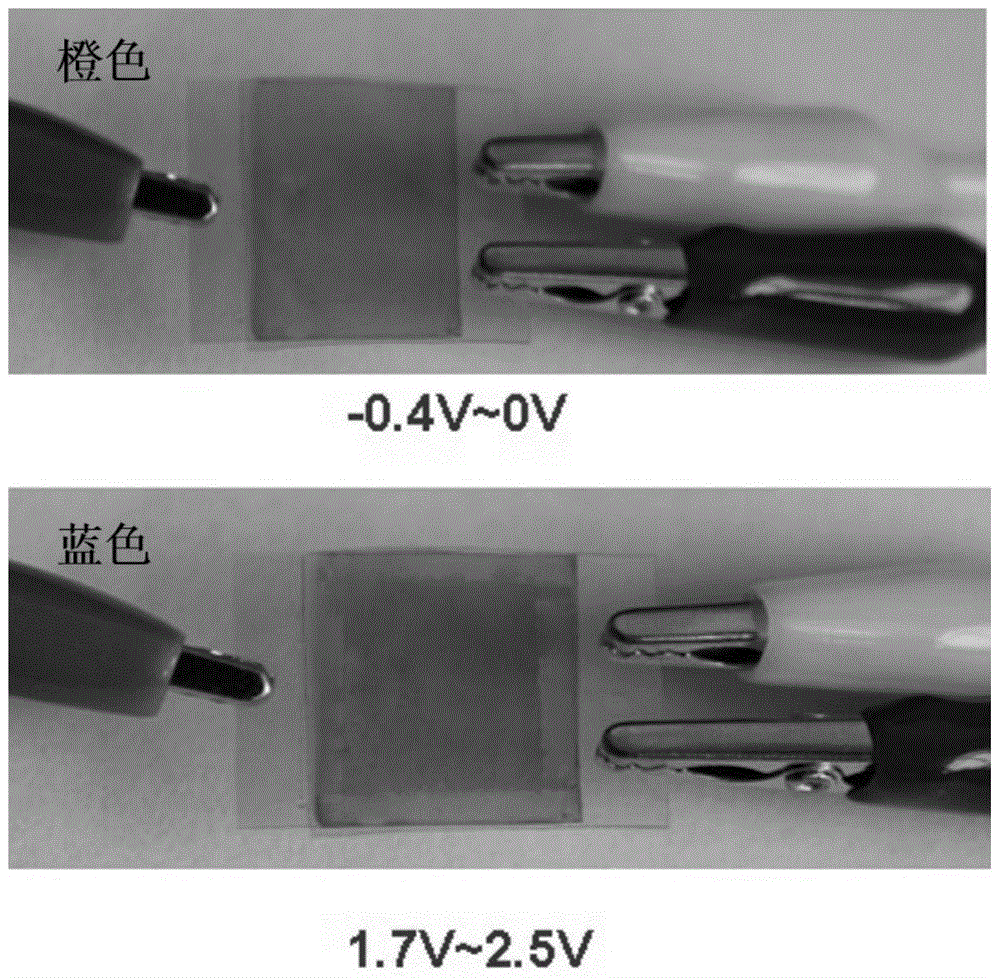

[0051] The monomer remains unchanged, the preparation method of the conductive polymer film and the assembly method of the device are the same as in Example 1, the difference is that the working electrode becomes an ITO-PET flexible electrode, so that the positive and negative electrode materials prepared are different, and what is obtained is a A solid-state electrochromic device based on a conductive polymer electrochromic material.

[0052] Step (1) prepares gel-like polymer electrolyte:

[0053] According to the mass ratio of electrolyte substances to CH 3 CN: PC: PMMA: LiClO 4 =70:20:7:3 Weigh the raw materials, wherein propylene carbonate (PC) (1g), chemically pure; polymethyl methacrylate (PMMA) (0.35g), requires a weight average molecular weight of (MW=120000g / mol), chemically pure; acetonitrile (ACN) (3.5g), chromatographically pure; lithium perchlorate (LiClO 4 ) (0.15g), analytically pure. Put the weighed PMMA and PC into a round-bottomed flask (50ml) with a ho...

Embodiment 3

[0061] The monomer remains unchanged, the preparation method of the conductive substrate of the electrode material, the conductive polymer film, and the assembly method of the device are the same as in Example 1, except that the composition ratio of the gel-like polymer electrolyte material is different.

[0062] Step (1) prepares gel-like polymer electrolyte:

[0063] According to the mass ratio of electrolyte substances to CH 3 CN: PC: PMMA: LiClO 4 =14:4:2:1 Weigh the raw materials, wherein propylene carbonate (PC) (0.8g) is chemically pure; polymethyl methacrylate (PMMA) (0.4g) requires a weight average molecular weight of (MW=120000g / mol), chemically pure; Acetonitrile (ACN) (2.8g), chromatographically pure; Lithium perchlorate (LiClO 4 ) (0.2g), analytically pure. Put the weighed PMMA and PC into a round-bottomed flask (50ml) with a hollow stopper, and put them in an oven at a constant temperature of 70°C for 18h to make the PMMA well swell in the PC. Add the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com