Novel sewage pump cutting device

A technology for cutting devices and sewage pumps, which is applied to components, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as complex manufacturing processes, reduced reliability and service life, and increased costs. Effects of particle clogging and fiber entanglement, improved non-clogging performance, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in detail:

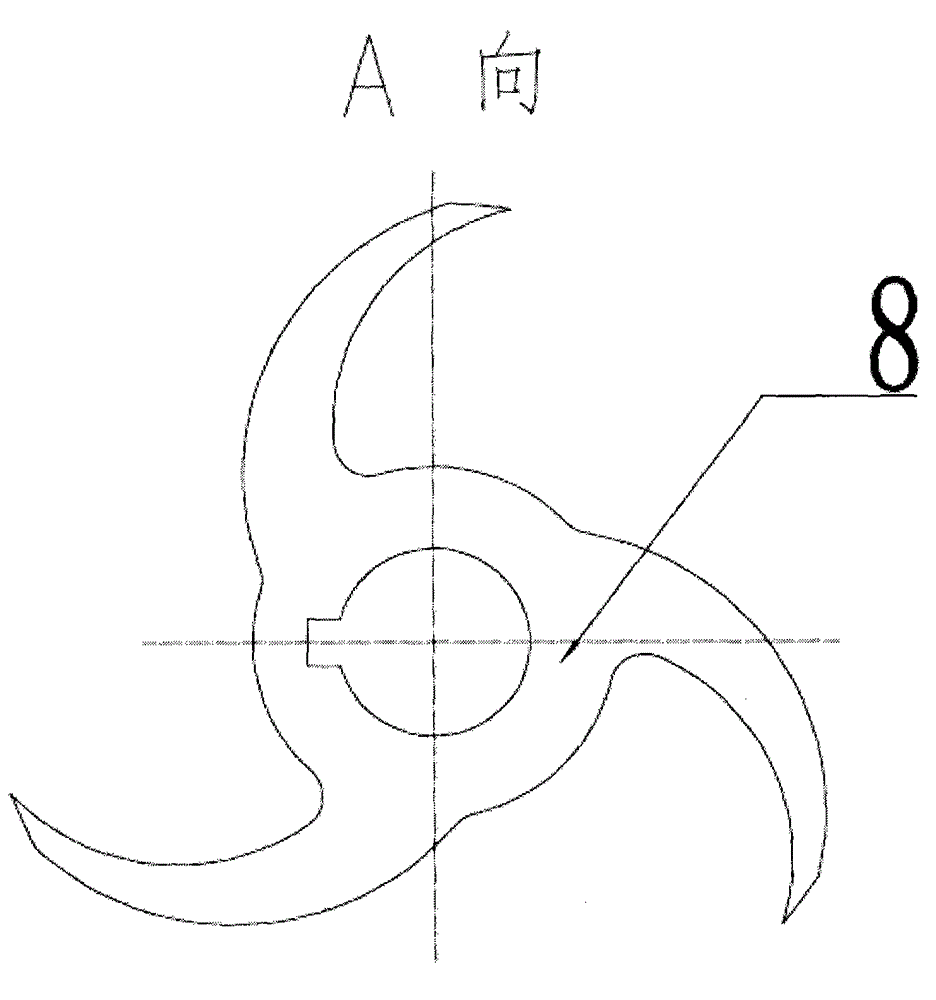

[0016] figure 1 Among them, a new type of sewage pump cutting device, including bearings (1), mechanical seals (2), coupling keys (3), impellers (4), pump shafts (5), front cover plates (6), mouth rings (7 ), cutting head (8), round nut (9), pump body (10), impeller inlet (11), etc. Cutter device The cutter head (8) is installed in front of the impeller inlet (11), and rotates synchronously with the pump shaft (5) and the impeller (4).

[0017] When the pump is running, the motor drives the pump shaft and the bearing supports to drive the impeller (4) and the cutting head (8) to rotate synchronously, and the sewage containing long fibers and large particles flows from the suction port of the sewage pump through the impeller (4) to do work and discharge to the sewage pump. In the sewage pipe. When long fibers and the like flow through the cutting head (8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com