Fire barrier belt with steel mesh frame rock wool board and construction method for fire barrier belt

A technology of fire isolation belt and steel mesh frame, which is used in fire prevention, climate change adaptation, building components, etc., can solve the problems of falling and hurting people, cracking of rock wool boards, and inability to ensure that rock wool boards can effectively bear their own weight and withstand wind pressure. , to achieve the effect of improving safety and solving potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

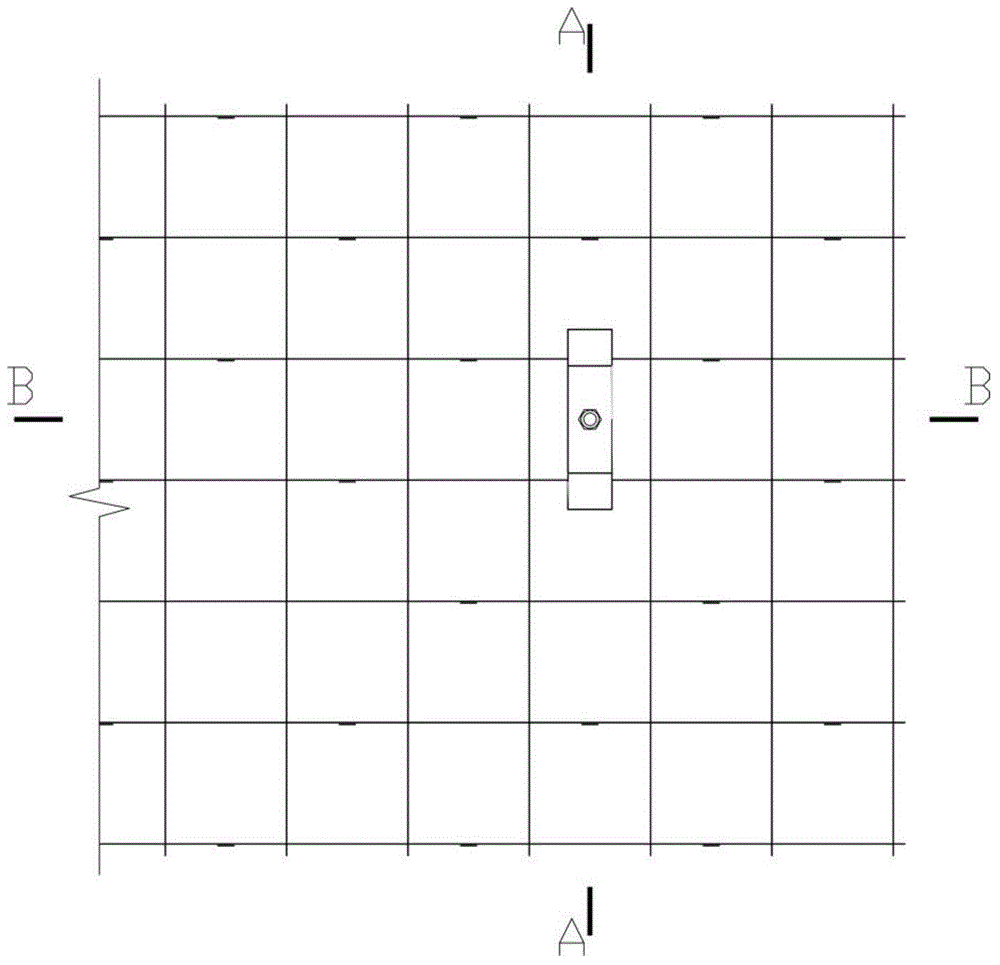

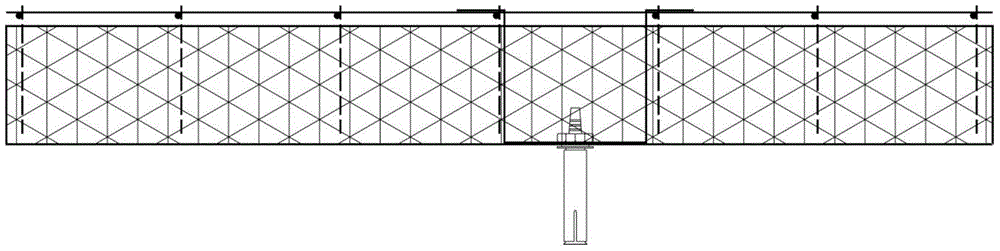

[0016] Such as figure 1 As shown, the fire isolation belt of steel wire frame rock wool board is set on the outside of the base wall, and it includes from inside to outside: cement mortar leveling layer 2, steel wire frame rock wool board insulation layer 5, rubber powder polystyrene particle insulation Slurry leveling layer 6, anti-cracking mortar plastering layer 7, elastic primer bonding layer 8 and finishing layer 9.

[0017] The base wall body 1 is an ordinary brick wall, aerated concrete block wall and reinforced concrete wall, etc. The thickness depends on the specific construction conditions.

[0018] Cement mortar leveling layer 2 is leveled with 20 thick 1:2.5 cement mortar.

[0019] The insulation layer 5 of steel wire grid rock wool board is made of steel wire grid and rock wool board, and is fixed on the base wall 1 through U-shaped anchors 3 and expansion bolts 4; The steel wire is welded with the steel wire mesh with a mesh size of 50mm×50mm. The obliquely ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com