Conductive ink based on graphene composite material and preparation method thereof

A composite material and conductive ink technology, applied in inks, household appliances, applications, etc., can solve the problems of unfavorable lamellar structure and large specific surface area, restrict the development of graphene conductive ink, and graphene is easy to agglomerate, etc., so as to improve the easy agglomeration. Difficult to disperse, outstanding substantive features, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

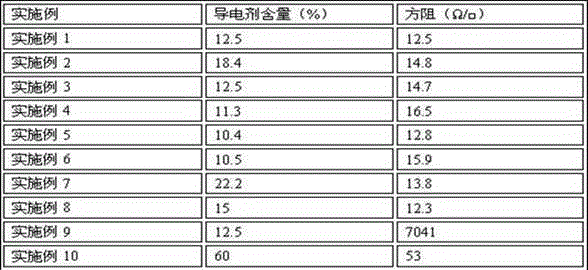

Examples

Embodiment 1

[0023] In the present embodiment, the number of mass parts of each raw material becomes: 1 part of carbon composite material of graphene composed of graphene and carbon black, 1 part of acrylic resin, by glycol methyl ether acetate: DBE: S150# by mass ratio It is 5 parts of mixed solvent mixed at 1:4:2, and 1 part of mixed auxiliary agent is mixed with defoamer: emulsifier: thickener at a mass ratio of 1:2:1.

[0024] The preparation steps of a kind of preparation method based on the conductive ink of graphene composite provided by the invention are as follows:

[0025] (a) Preparation of the carrier: mix the acrylic resin with the mixed solvent and put it in the reaction kettle, then place the reaction kettle in an oven at 80°C for 0.5h to completely dissolve the resin;

[0026] (b) Preparation of conductive paste: fully mix the carrier with the graphene carbon composite material and defoamer and then send it into the dispersion tank for stirring, wherein the weight of the gr...

Embodiment 2

[0030] In the present embodiment, the mass fraction of each raw material becomes: 2.7 parts of carbon composite materials of graphene composed of graphene and carbon black, 1 part of acrylic resin, by glycol methyl ether acetate: DBE: S150# by mass ratio It is 10 parts of mixed solvent mixed in 1:4:2, and 1 part of mixed auxiliary agent made of defoamer: emulsifier: thickener in a mass ratio of 1:2:1.

[0031] The preparation steps of a kind of preparation method based on the conductive ink of graphene composite provided by the invention are as follows:

[0032] (a) Preparation of the carrier: mix the acrylic resin with the mixed solvent and put it in the reaction kettle, then place the reaction kettle in an oven at 80°C for 0.5h to completely dissolve the resin;

[0033] (b) Preparation of conductive paste: fully mix the carrier with the graphene carbon composite material and defoamer and then send it into the dispersion tank for stirring, wherein the weight of the graphene c...

Embodiment 3

[0037] In the present embodiment, the mass fraction array of each raw material becomes: 6.3 parts of the carbon composite material of the graphene that graphene and acetylene black form, 10 parts of epoxy resins, by glycol methyl ether acetate: DBE: S150# by mass 30 parts of mixed solvent with a ratio of 1:4:2, and 4 parts of admixture mixed with thickener: leveling agent: wetting and dispersing agent at a mass ratio of 1:1:4.

[0038] The preparation steps of a kind of preparation method based on the conductive ink of graphene composite provided by the invention are as follows:

[0039] (a) Preparation of the carrier: Mix the epoxy resin with the mixed solvent and put it in the reaction kettle, then place the reaction kettle in an oven at 100°C for 5 hours to make the resin completely dissolve;

[0040] (b) Preparation of conductive paste: fully mix the carrier with the graphene carbon composite material and defoamer and then send it into the dispersion tank for stirring, whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com