Method for preparing gamma-valerolactone by liquid-phase hydrogenation and catalyst used by same

A liquid-phase hydrogenation, valerolactone technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of high production process risks and production costs. high selectivity, simple operation and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

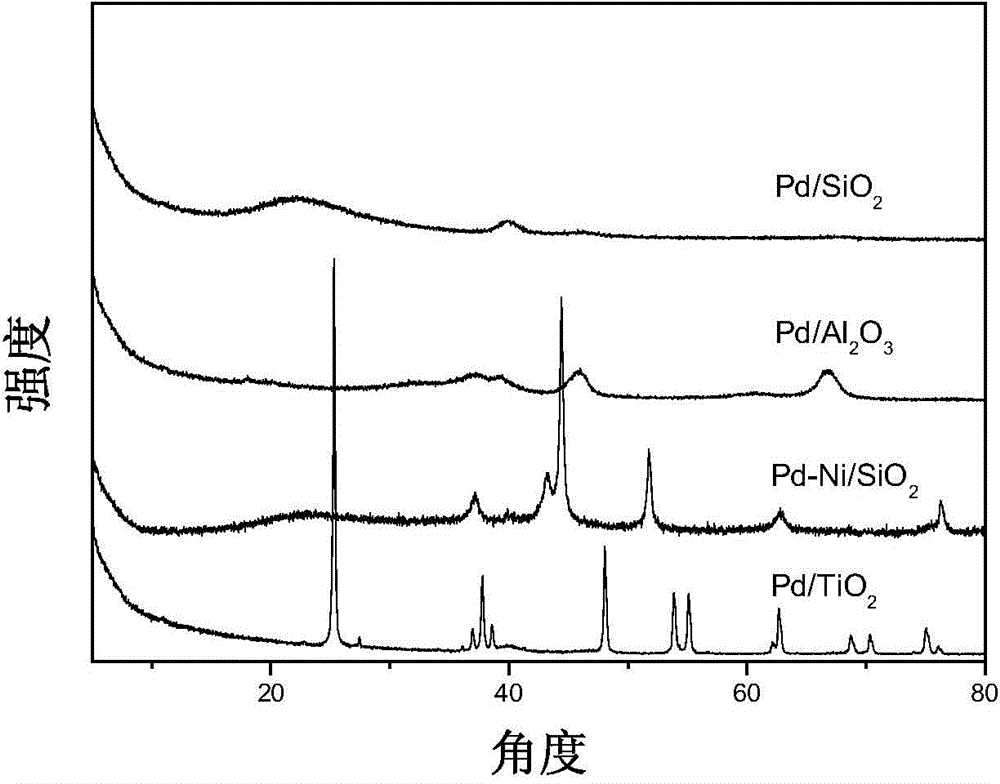

[0030] The preparation of embodiment 1 supported palladium catalyst:

[0031] Take PdCl proportionally 2 Add the solution into the titanium oxide aqueous solution (Pd: titanium oxide = 1:19, weight ratio), stir evenly at room temperature and adjust the pH to Pd 2+ After the precipitation was complete, sodium borohydride (Pd:sodium borohydride=1:10, molar ratio) was added and stirring was continued for 2 hours. The obtained solution is filtered and dried to prepare a supported palladium catalyst, and palladium metal nanoparticles are evenly distributed on the carrier.

[0032] Titanium oxide is used in this embodiment. In other embodiments, common oxides such as silicon oxide, aluminum oxide, and nickel oxide, and activated carbon can also be used to achieve the same effect.

[0033] In this embodiment, PdCl is used 2 . In other embodiments it can also be Pd(NO 3 ) 2 or Pd(Ac) 2 , all achieve the same effect.

[0034] Sodium borohydride is used as reducing agent in thi...

Embodiment 2

[0036] The preparation of embodiment 2 supported palladium-nickel alloy catalysts:

[0037] Take PdCl proportionally 2 and Ni(NO 3 ) 2Add the solution into the aqueous solution of silicon oxide (Pd:Ni:SiO2=0.001:0.4:0.59 weight ratio), stir well at room temperature and adjust the pH to Pd 2+ and Ni 2+ Precipitation is complete, add sodium borohydride (Pd:NaBH 4 =1:10, molar ratio) and continued to stir for 2 hours. The resulting solution was filtered and dried to prepare a supported palladium-nickel catalyst.

[0038] Silicon oxide is used in this embodiment. In other embodiments, common oxides such as titanium oxide and aluminum oxide and activated carbon can also be used to achieve the same effect.

[0039] In this embodiment, PdCl is used 2 . In other embodiments it can also be Pd(NO 3 ) 2 or Pd(Ac) 2 , all achieve the same effect.

[0040] In this example, Ni(NO 3 ) 2 . In other embodiments it can also be NiCl 2 or Ni(Ac) 2 , all achieve the same effect. ...

Embodiment 3

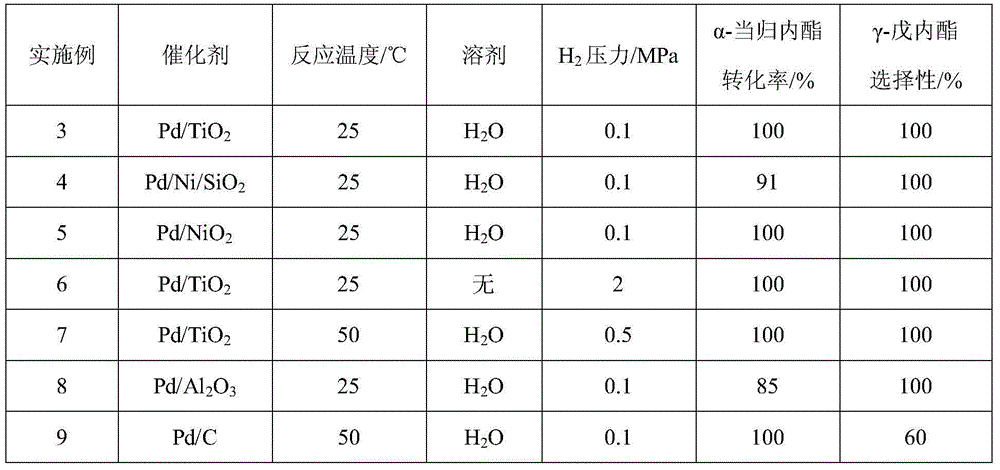

[0043] Example 3 α-angelica lactone hydrogenation reaction

[0044] Use the Pd / TiO that embodiment 1 prepares 2 Catalyst is carried out to prepare gamma-valerolactone by liquid-phase hydrogenation of alpha-angelica lactone, in round bottom flask, load catalyst, consumption is about 10% (accounting for alpha-angelica lactone mass percentage), solvent (water) dilution ratio About 50:1 (water: α-angelica lactone, volume ratio), the reaction temperature is 25 ℃, under the pressure of hydrogen balloon (0.1MPa) for 1 hour, α-angelica lactone 100%, γ-amyloid The lactone selectivity is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com