Room-temperature synthetic type polycarboxylic high performance water-reducing agent and preparation method thereof

A synthetic polycarboxylic acid, high-performance technology, applied in the field of room temperature synthetic polycarboxylic acid-based high-performance water reducer and preparation, can solve the problems of cumbersome production process, no energy saving, unsafe, etc., to simplify the process, improve the Efficiency, excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

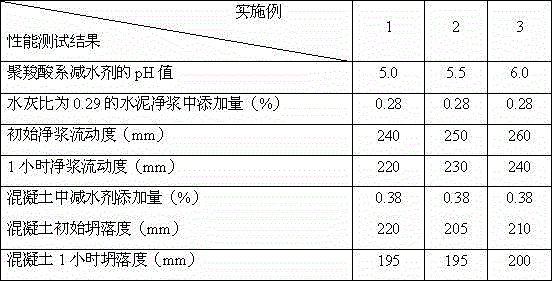

Examples

Embodiment 1

[0053] A high -performance water reduction agent of a normal temperature synthetic polycar carboxylic acid system, which is 100, acrylics 10, methyl acrylic 0, sodium acrylics, 0, sodium methyl acrylics, 0, hydrogen peroxide 1.1 1.1, Oremium sulfate 0.5, L-anti-severic acid 0.16, sodium diexulfate 0.16, cymbicobacidic acid 0, cymbic acid 0, sodium hydroxide 10 and 110 water.

[0054] The synthesis step of the water reduction agent is as follows:

[0055] Pyrite, pyrine, sodium hydroxide and water.

[0056](2) Actinophyll polyoxide ether, hydrogenation, ammonium sulfate, sodium acrylsulfonate, sodium methyl acrylic sulfonate, and water accounted for 20%of the total water, and put it into a polymerization reactor and stir well.

[0057] (3) Made of acrylic, methyl acrylic acid and 20%of water for a total water consumption, to make solution A, and to make L-aslocodicic acid, sodium diexic acid, cymbic acid, dexyl propionic acid, and 20%of the water consumption of waterB.When the temp...

Embodiment 2

[0062] A high -performance water reduction agent of a normal temperature synthetic polycarboxylic acid system, which is 100, acrylics 15, methyl acrylic acid 3, sodium acrylics, sodium methacryonal, sodium methyl acrylics, Ammonium sulfate 2.0, L-anti-hemoglobin 0.20, sodium diete sodium sulfate 0.23, cymbicobacidic acid 0.3, cymbic acid 0.2, sodium hydroxide 14 and 150 water.

[0063] The synthesis step of the water reduction agent is as follows:

[0064] Pyrite, pyrine, sodium hydroxide and water.

[0065] (2) Actinophyll polyoxide ether, hydrogenation, ammonium sulfate, sodium acrylsulfonate, sodium methyl acrylic sulfonate, and water accounted for 20%of the total water, and put it into a polymerization reactor and stir well.

[0066] (3) Made of acrylic, methyl acrylic acid and 20%of water for a total water consumption, to make solution A, and to make L-aslocodicic acid, sodium diexic acid, cymbic acid, dexyl propionic acid, and 20%of the water consumption of waterB.When the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com