Manufacturing method for fiberboard with electromagnetic shielding function

A technology of functional fibers and manufacturing methods, which is applied in the direction of manufacturing tools, flat products, and pretreatment of molding materials, and can solve the electromagnetic wave shielding function of wood composite or fiberboard. There is little research on the electromagnetic wave shielding function, and no market-oriented application, popularization, and industrialization technology have been formed. Problems such as unsolved bottlenecks achieve the effect of simple manufacturing process, increased added value, and broadened application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

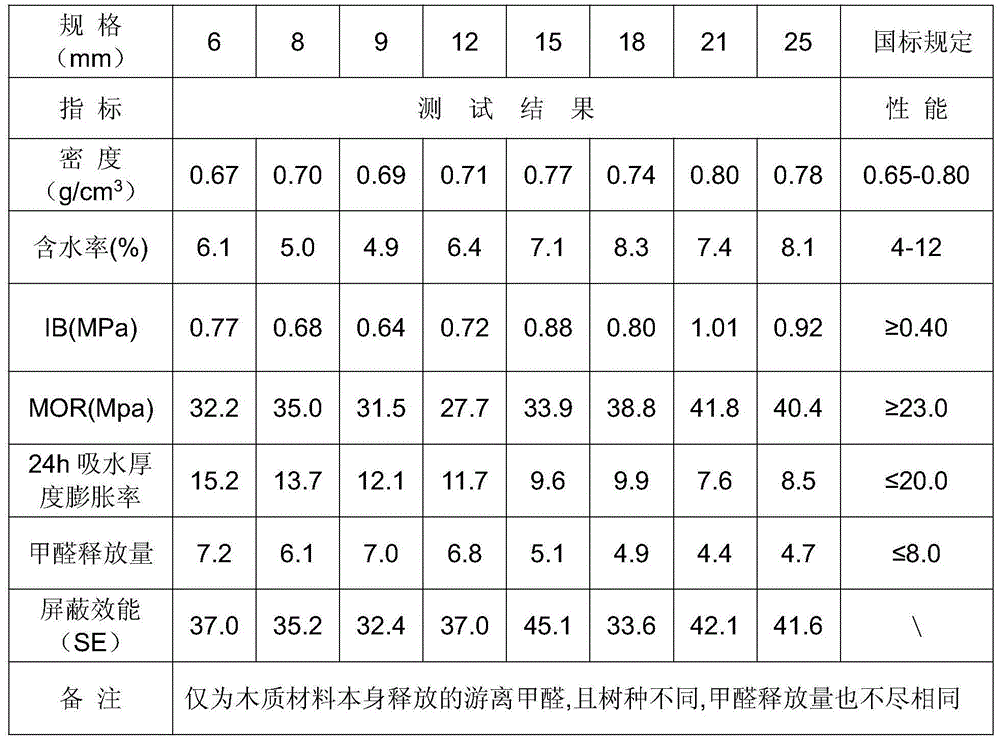

Embodiment 1

[0020] (1) Preparation of powdery composite conductive filler

[0021] The manufacturing method of the composite conductive filler is as follows: 40 parts of metal aluminum powder, 20 parts of carbon black, 10 parts of graphite, 5.0 parts of talcum powder, each component is uniformly mixed according to the weight ratio, and crushed to a mesh number of 400-500 mesh, a particle size of 2.0- 3.0 microns, spare.

[0022] (2) Panel production process

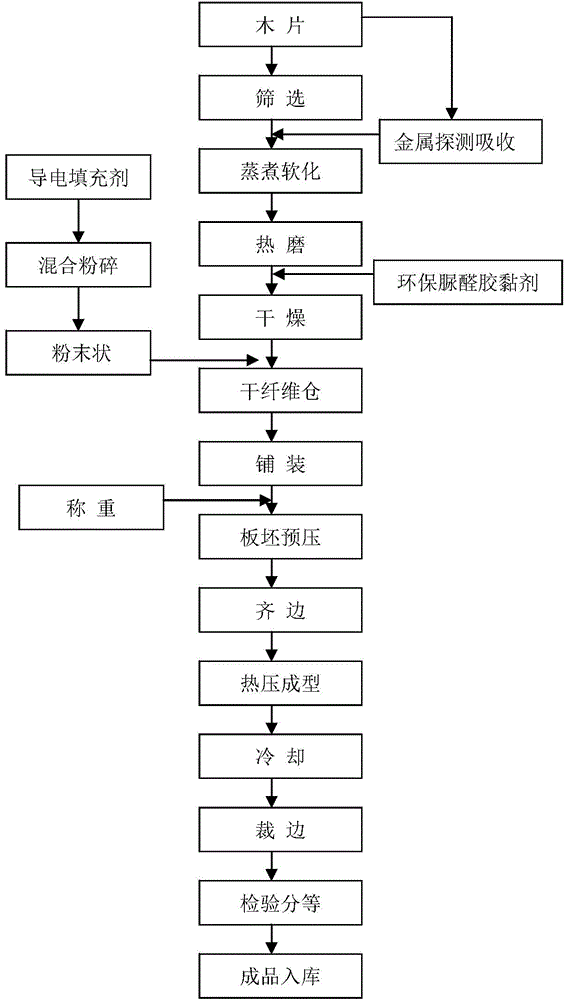

[0023] After the powdery composite conductive filler is prepared, follow the production process of the above-mentioned fiberboard figure 1 The process steps produce electromagnetic shielding fiberboard with a thickness of 2.5-25mm.

[0024] 1). Classify and store wood raw materials. The storage site should be dry, with good drainage conditions and fire-fighting facilities. The principle of first-come, first-served should be adopted. The storage time should not be too long, and the moisture content should be controlled at 40% to 60...

Embodiment 2

[0038] (1) Preparation of powdery composite conductive filler

[0039] The manufacturing method of the powdery composite conductive filler is as follows: 60 parts of metal aluminum powder, 30 parts of carbon black, 20 parts of graphite, 10 parts of talcum powder, each component is uniformly mixed according to the weight ratio, and crushed to a mesh number of 200-300 mesh, The particle size is 2.0-3.0 microns, ready for use.

[0040] (2) Panel production process

[0041] After the powdery composite conductive filler is prepared, follow the production process of the above-mentioned fiberboard figure 1 The process steps produce electromagnetic shielding fiberboard with a thickness of 2.5-25mm.

[0042] 1). Classify and store wood raw materials. The storage site should be dry, with good drainage conditions and fire-fighting facilities. The principle of first-come, first-served should be adopted. The storage time should not be too long, and the moisture content should be control...

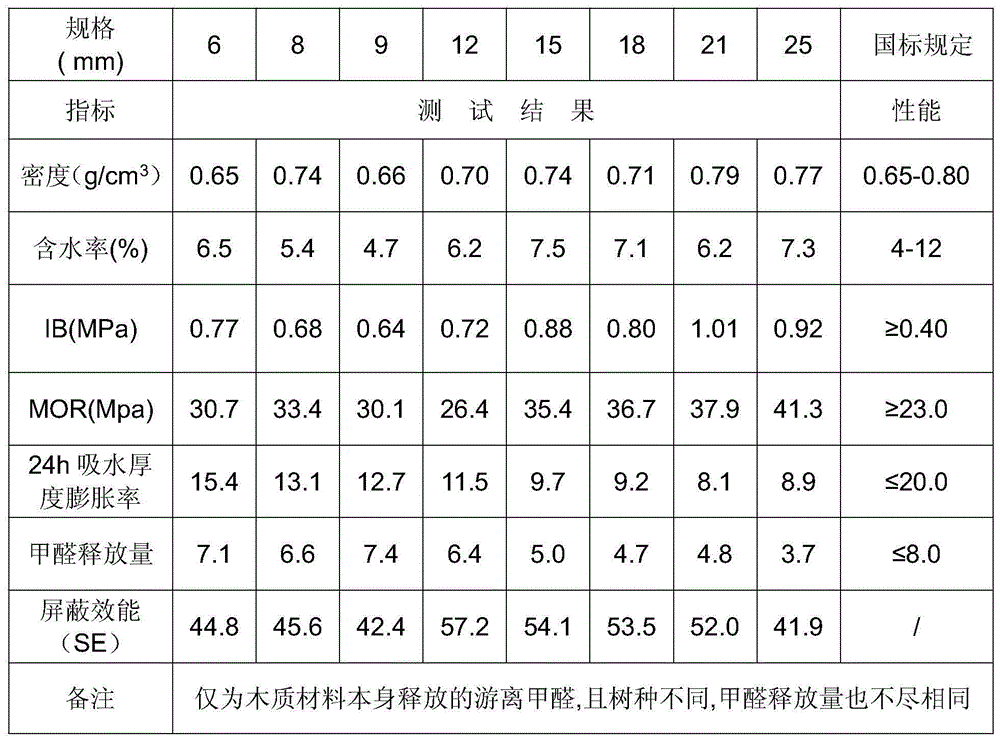

Embodiment 3

[0056] (1) Preparation of composite conductive filler

[0057] The manufacturing method of the composite conductive filler is as follows: 50.0 parts of metal aluminum powder, 25.0 parts of carbon black, 15.0 parts of graphite, 7.5 parts of talcum powder, each component is uniformly mixed according to the weight ratio, and crushed until the mesh number is 300-400 mesh, and the particle size is 3.0-4.0 microns, spare.

[0058] (2) Panel production process

[0059] After the powdery composite conductive filler is prepared, follow the production process of the above-mentioned fiberboard figure 1 The process steps produce electromagnetic shielding fiberboard with a thickness of 2.5-25mm.

[0060] 1). Classify and store wood raw materials. The storage site should be dry, with good drainage conditions and fire-fighting facilities. The principle of first-come, first-served should be adopted. The storage time should not be too long, and the moisture content should be controlled at 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com