Attapulgite Clay Slurry for Li-ion Batteries

A technology of attapulgite clay and lithium-ion batteries, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of blocking lithium-ion conduction, high binder content, and reduced capacity, so as to reduce slurry costs and energy The effect of reducing power consumption and reducing the probability of hole plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

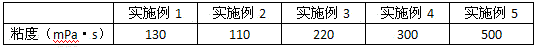

Embodiment 1

[0016] Embodiment 1: select the attapulgite clay that the purity of Jiangsu Xuyi produces is 98% to purify fiber powder; The fiber average length in the fiber structure of this product is 0.75 micron, and the average diameter is 0.05 micron; Weigh this purified mineral powder 500.0g, polyethylene 37.5 g of diol was dissolved in 650.0 g of water, and stirred at a high speed for 30 minutes; finally, 62.5 g of aqueous polyvinylidene fluoride was added, and stirred evenly at a slow speed to obtain an attapulgite clay slurry.

Embodiment 2

[0017] Example 2: Select attapulgite clay with a purity of 98% from Xuyi, Jiangsu Province to purify fiber powder; the average fiber length in the fiber structure of this product is 1 micron, and the average diameter is 0.75 micron; 500.0 g of purified mineral powder, polyethylene glycol Dissolve 2 g of alcohol in 745.0 g of water and stir at high speed for 30 minutes; finally add 3 g of water-based polyvinylidene fluoride and stir evenly at a slow speed to obtain attapulgite clay slurry.

Embodiment 3

[0018] Embodiment 3: choose the attapulgite clay that the purity of Jiangsu Xuyi produces is 98% to purify fiber powder; The fiber average length in the fiber structure of this product is 1 micron, and the average diameter is 0.75 micron; Take carboxymethyl cellulose 15.0g, dissolve In 460.0 g of water, weigh 500.0 g of purified mineral powder and add it into the solution, and stir at high speed for 45 minutes; finally add 25 g of styrene-butadiene latex, and stir evenly at a slow speed to obtain attapulgite clay slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com