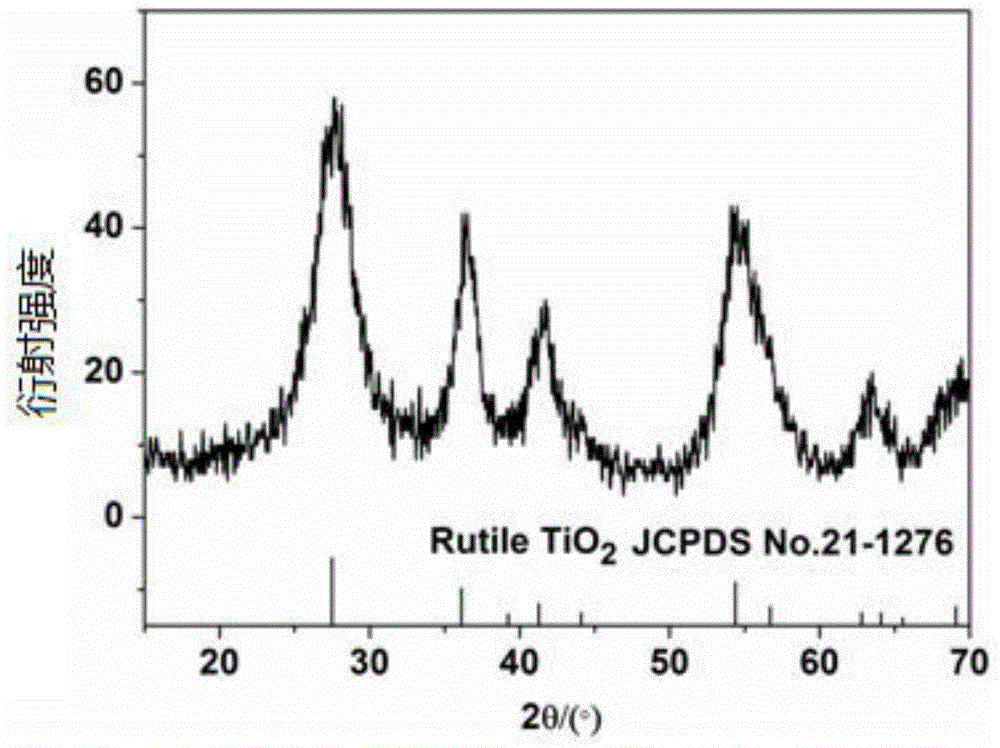

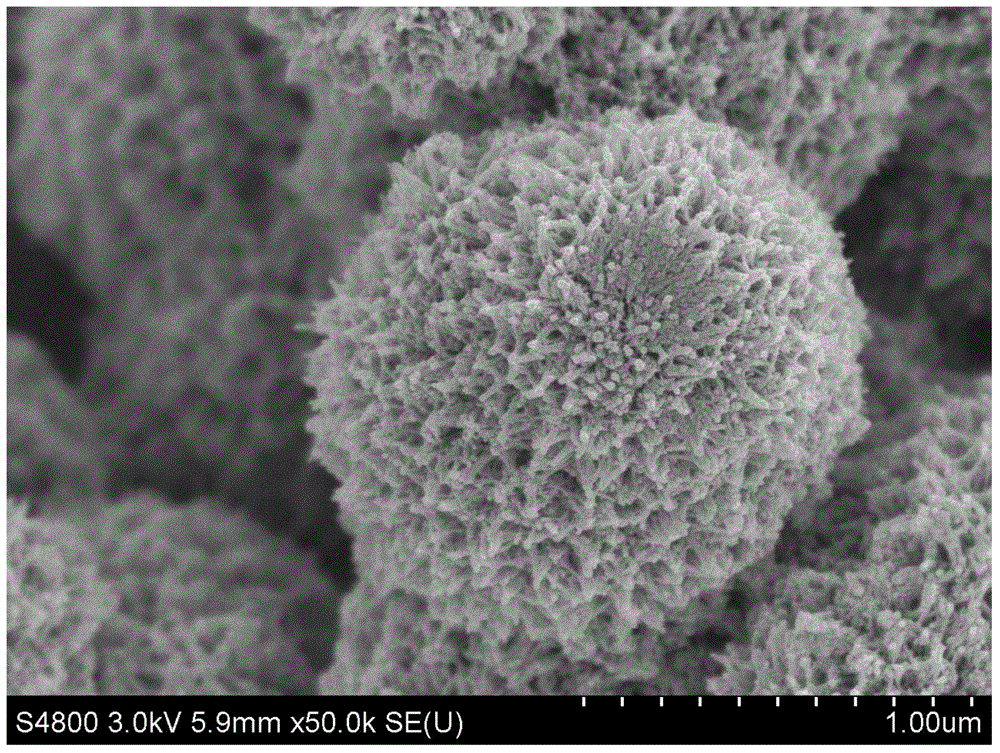

Low-temperature manufacturing method of lithium ion battery negative material rutile-type titanium dioxide microsphere

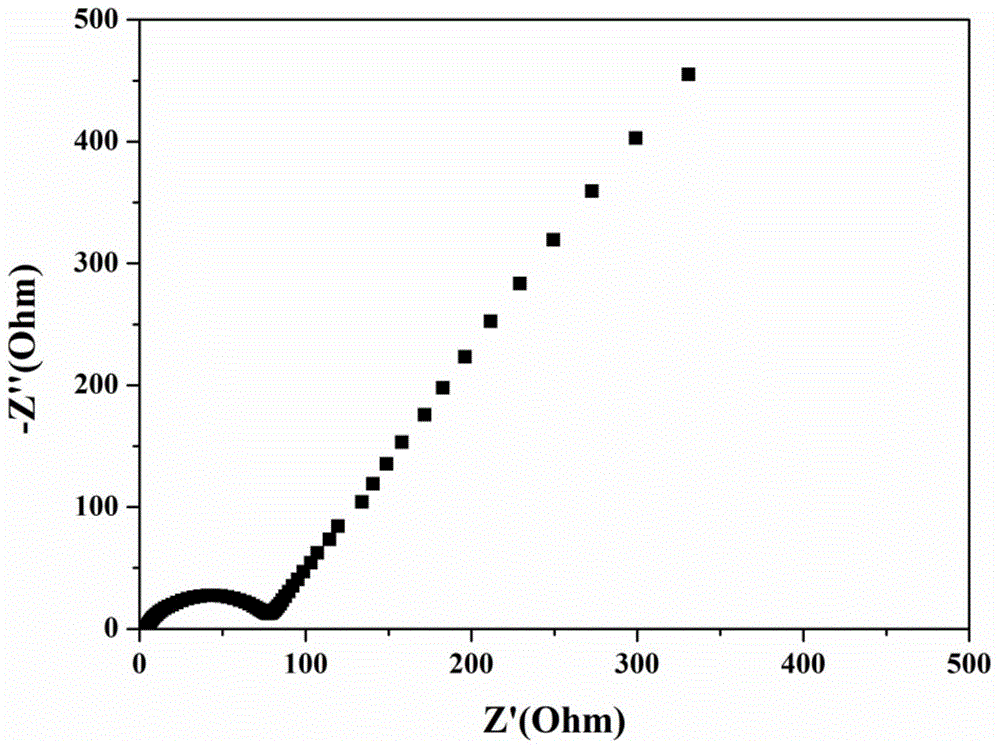

A lithium-ion battery, rutile technology, applied in the direction of titanium dioxide, battery electrodes, titanium oxide/hydroxide, etc., can solve the problems of difficult control of product morphology, poor electrochemical performance, easy introduction of impurities, etc., to avoid high temperature Solid-phase reaction process, good crystallinity, and the effect of shortening the diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A low-temperature preparation method of rutile-type titanium dioxide microspheres, a lithium-ion battery negative electrode material, comprising the following steps:

[0025] 1) Measure 5mL of tetrabutyl titanate, 35mL of acetic acid and 10mL of ethylene glycol, mix well to obtain a mixed solution, and fully magnetically stir the mixed solution at room temperature for 30 minutes to obtain a reaction precursor;

[0026] 2) The reaction precursor solution was hydrothermally reacted at 150° C. for 18 hours, and then centrifuged after natural cooling; the hydrothermal reaction was carried out by placing the reaction precursor solution in a hydrothermal reaction kettle lined with polytetrafluoroethylene, The filling ratio of the hydrothermal reactor used is 30% to 70%;

[0027] 3) Wash the precipitate obtained by centrifugation for 3 times with deionized water, then with absolute ethanol for 3 times, and then dry at 60° C. for 2 hours to obtain rutile titanium dioxide micros...

Embodiment 2

[0030] A low-temperature preparation method of rutile-type titanium dioxide microspheres, a lithium-ion battery negative electrode material, comprising the following steps:

[0031] 1) Measure 6mL of tetrabutyl titanate, 30mL of acetic acid and 40mL of ethylene glycol, mix well to obtain a mixed solution, and fully magnetically stir the mixed solution at room temperature for 20 minutes to obtain a reaction precursor;

[0032] 2) The reaction precursor solution was hydrothermally reacted at 170° C. for 10 hours, and then centrifuged after natural cooling; the hydrothermal reaction was carried out by placing the reaction precursor solution in a hydrothermal reaction kettle lined with polytetrafluoroethylene, The filling ratio of the hydrothermal reactor used is 30% to 70%;

[0033] 3) Wash the precipitate obtained by centrifugation for 3 times with deionized water, then with absolute ethanol for 3 times, and then dry at 50° C. for 3 hours to obtain rutile titanium dioxide micros...

Embodiment 3

[0036] A low-temperature preparation method of rutile-type titanium dioxide microspheres, a lithium-ion battery negative electrode material, comprising the following steps:

[0037] 1) Measure 2mL of tetrabutyl titanate, 10mL of acetic acid and 30mL of ethylene glycol, mix well to obtain a mixed solution, and fully magnetically stir the mixed solution at room temperature for 10 minutes to obtain a reaction precursor;

[0038] 2) The reaction precursor solution was hydrothermally reacted at 150° C. for 24 hours, and then centrifuged after natural cooling; the hydrothermal reaction was carried out by placing the reaction precursor solution in a hydrothermal reaction kettle lined with polytetrafluoroethylene, The filling ratio of the hydrothermal reactor used is 30% to 70%;

[0039] 3) The precipitate obtained by centrifugation was first washed once with deionized water, then washed twice with absolute ethanol, and then dried at 70° C. for 2 hours to obtain rutile titanium dioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com