Adsorbing material performance testing device and using method thereof

A technology for testing devices and adsorption materials, applied in the direction of using substance absorption and weighing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

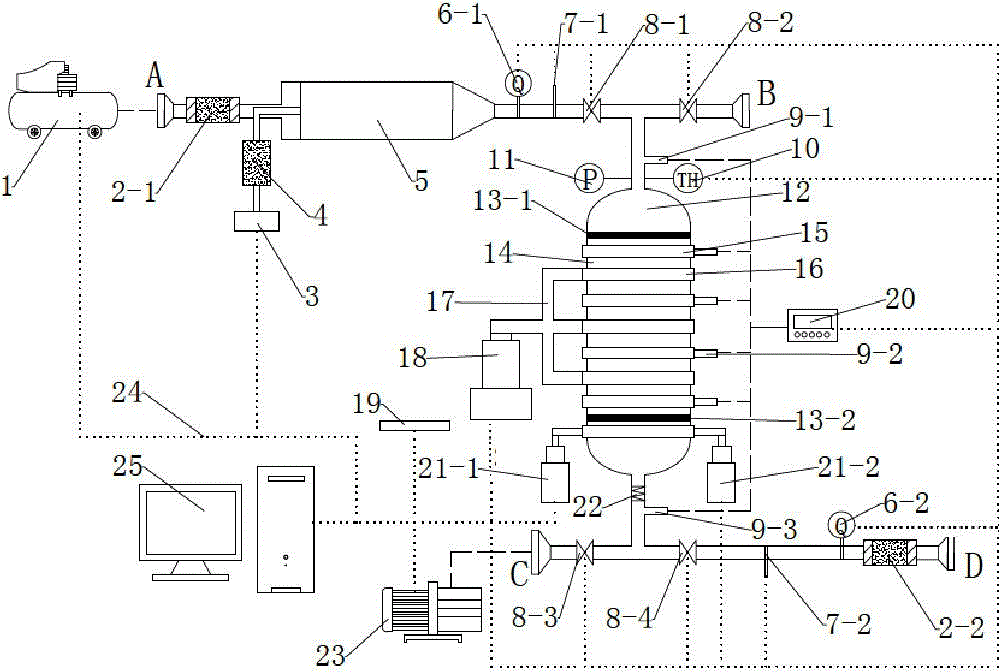

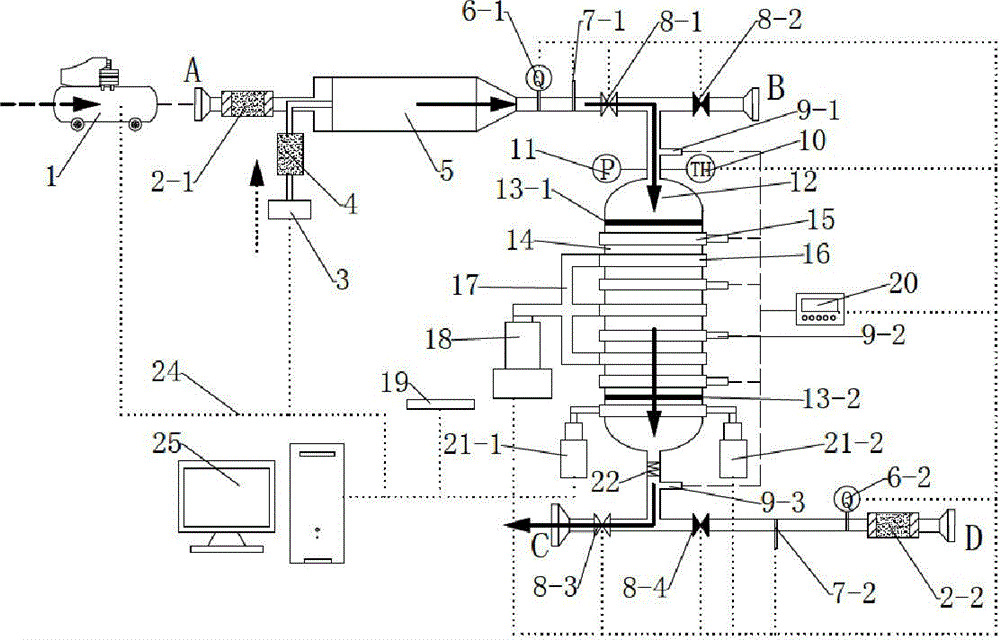

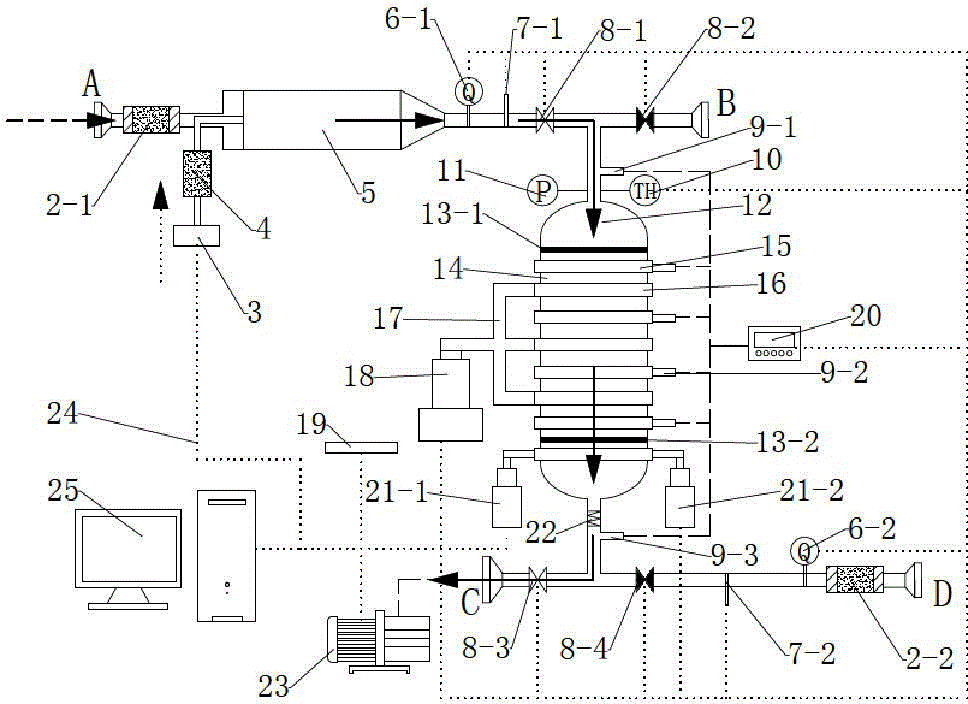

Image

Examples

Embodiment 1

[0035] Application environment: To study the influence of different pressures on the fixing ability of zeolite molecular sieves at zero humidity and a certain temperature.

[0036] Such as Figure 4 As shown, the gas mixer 5 includes a test gas air pipe 5a, a swirl blade 5b, a housing 5c, a baffle 5d, a test gas outlet 5e and a solid blade shaft 5f, wherein: 6 swirl blades 5b are coaxially arranged, two The gaps between adjacent swirl blades 5b form 6 gas paths, and three baffles 5d are arranged at intervals at the front ends of the 3 gas paths; the test gas gas pipe 5a is connected to the solid blade shaft 5f, and the corresponding three gas paths at the end of the test gas gas pipe 5a The gas paths provided with baffles are three test gas outlets 5e. The three air paths without baffles communicate with the air pipes, which are air swirl channels. The test gas passes through the test gas pipe 5a, and enters the baffled swirl channel through the test gas outlet 5e, and the ai...

Embodiment 2

[0041] Application environment: test the interaction between different gas components in the adsorption process of activated carbon to multi-component organic gases at normal temperature and pressure, such as competitive inhibition of adsorption, synergistic adsorption, substances with strong adsorption capacity for weak adsorption Substance adsorption, etc. Test gas selection xylene, toluene, n-propanol, ethanol.

[0042] According to Figure 2(a), when studying the adsorption of activated carbon on multi-component mixed gases at normal temperature and pressure, the air compressor 1 is used as the system power device, and the test gas generation source is a high-pressure gas tank. Gas partial pressure, calculate the flow ratio of air and mixed gas, set up 4 subsection gas sampling ports 9-2, monitor the concentration of mixed gas in each section at the same time in the same adsorption process respectively. Then the adsorbent cartridge 14 is filled with activated carbon, and f...

Embodiment 3

[0044] Application environment: To study the adsorption mechanism of modified activated carbon on formaldehyde, the adsorption temperature is 30°C, the humidity is 0, the desorption temperature is 120°C, the temperature is 0°C, and the pressure in the test section is 100kPa.

[0045] According to Figure 2(a), when studying the adsorption mechanism of modified activated carbon to formaldehyde, the air compressor 1 is used as the system power device, and the test gas generation source is a high-pressure formaldehyde gas tank. According to the partial pressure of the formaldehyde to be measured, the air and formaldehyde flow ratio. Then the modified activated carbon is filled in the adsorbent cylinder 14, and fixed on the adsorbent cylinder hoop 16, the swing cylinder 18 is screwed onto the electronic balance 19 to weigh the initial mass, and then the adsorbent cylinder 14 is screwed to the adsorption tank 12 Below, the reciprocating cylinder 21 docks and clamps the adsorbent car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com