Transmission pulley, method for producing such a pulley, and power transmission system comprising such a pulley

A power transmission and transmission belt technology, applied in the direction of belts/chains/gears, transmission devices, components with teeth, etc., can solve the problems of cost, price and complexity of the power transmission system of the belt with longitudinal grooves, and achieve firmness Effect of axially compact, strong pulleys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

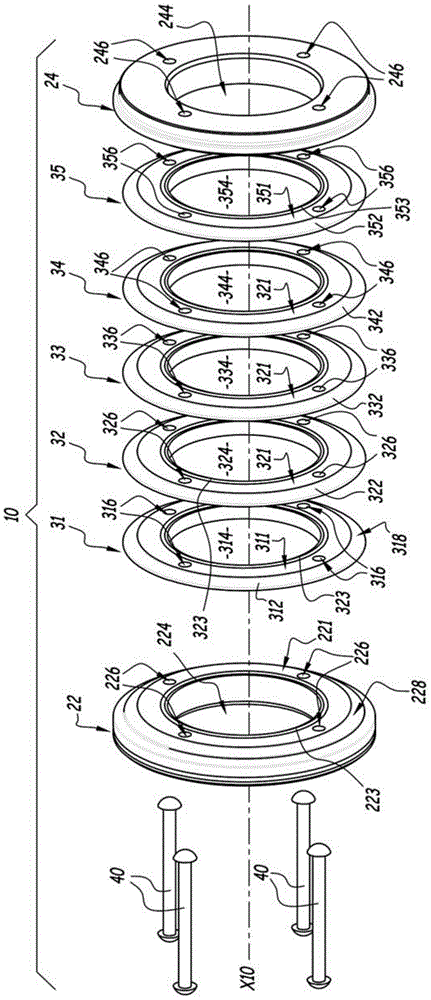

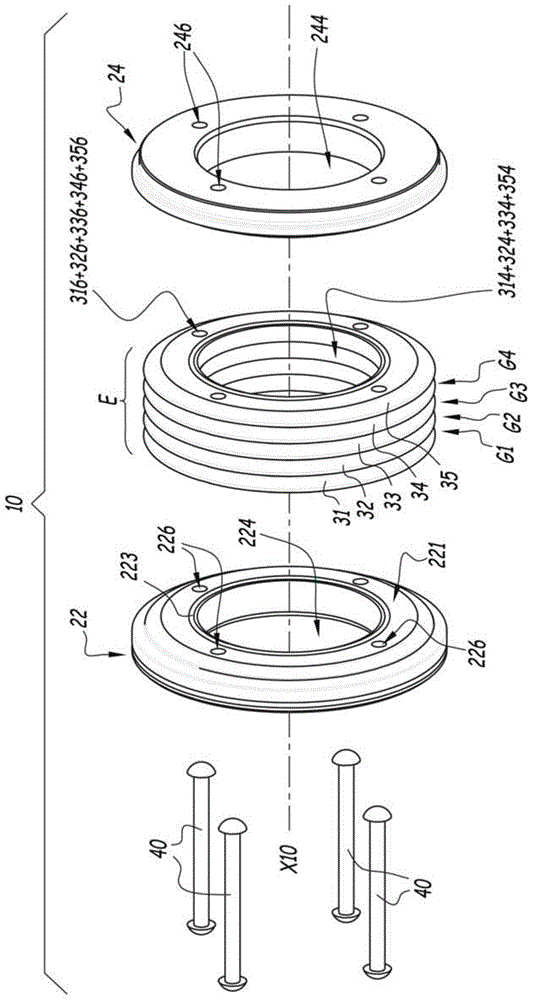

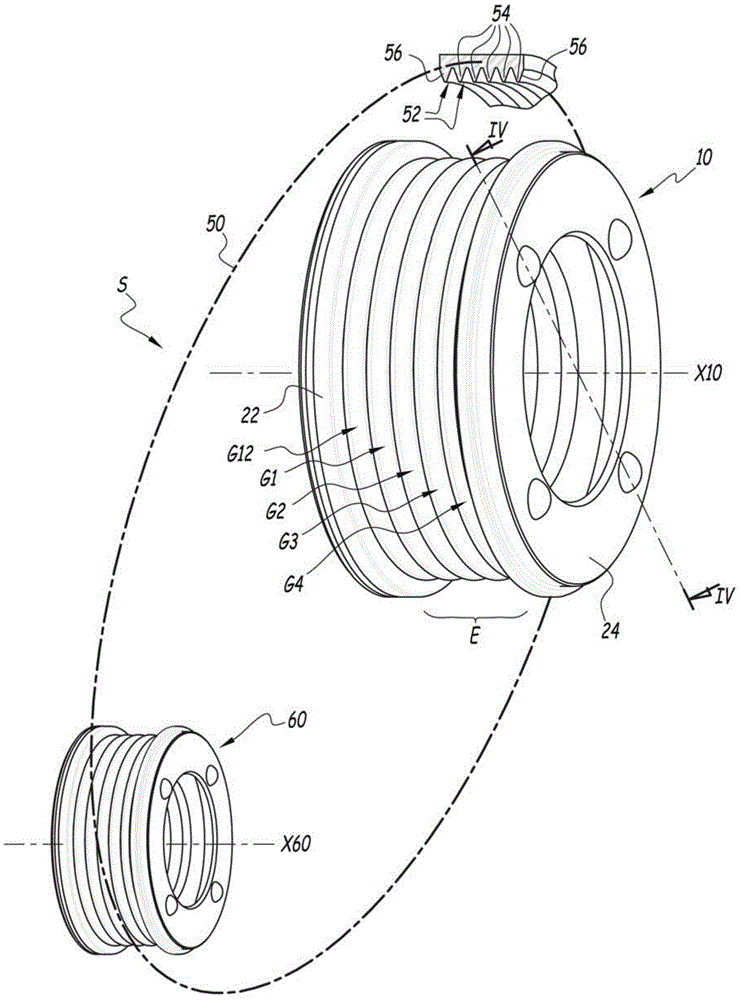

[0028] exist Figure 1 to Figure 4 The pulley 10 shown in is arranged to rotate about an axis of rotation X10, which is mounted on a support such as a flywheel, idler roller, or shaft (not shown). The pulley 10 comprises a first end cap 22 and a second end cap 24 , of annular shape, centered on the axis X10 in the mounted configuration of the pulley 10 , which define the ends of the pulley 10 along said axis X10. In other words, the end cap 22 constitutes the image 3 as well as Figure 4 The left side is along the first shaft end of the axis X10 of the pulley 10, while the end cover 24 is defined in image 3 as well as Figure 4 The second shaft end of the opposite pulley 10 on the right. Five crowns 31 , 32 , 33 , 34 , and 35 are arranged between said end caps 22 and 24 and along the direction of said axis X10 , which are identical to each other and each other from end cap 22 to end cap 24 are arranged in a continuous order along the axis X10.

[0029] The crown 31 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com