A plunger return device for crankshaft connecting rod radial piston pump

A technology of crankshaft connecting rod and radial column, which is applied to the parts of the pumping device for elastic fluid, the parts of the variable displacement pump, the pump, etc., can solve the problem of affecting the service life of the pump, high pv value of the friction pair, fatigue damage And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

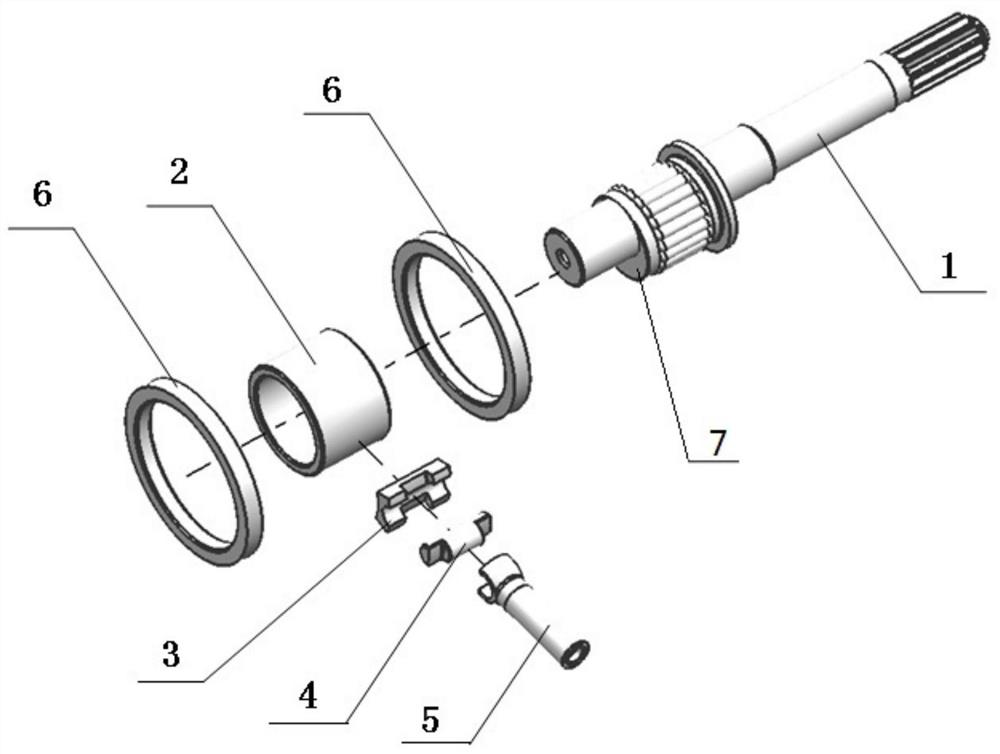

[0025] Such as Figure 1-5b , embodiment one,

[0026] A plunger return device for a crankshaft connecting rod type radial plunger pump, comprising a plunger 5, a pin shaft 4, a shaft pad 3 and a collar 6;

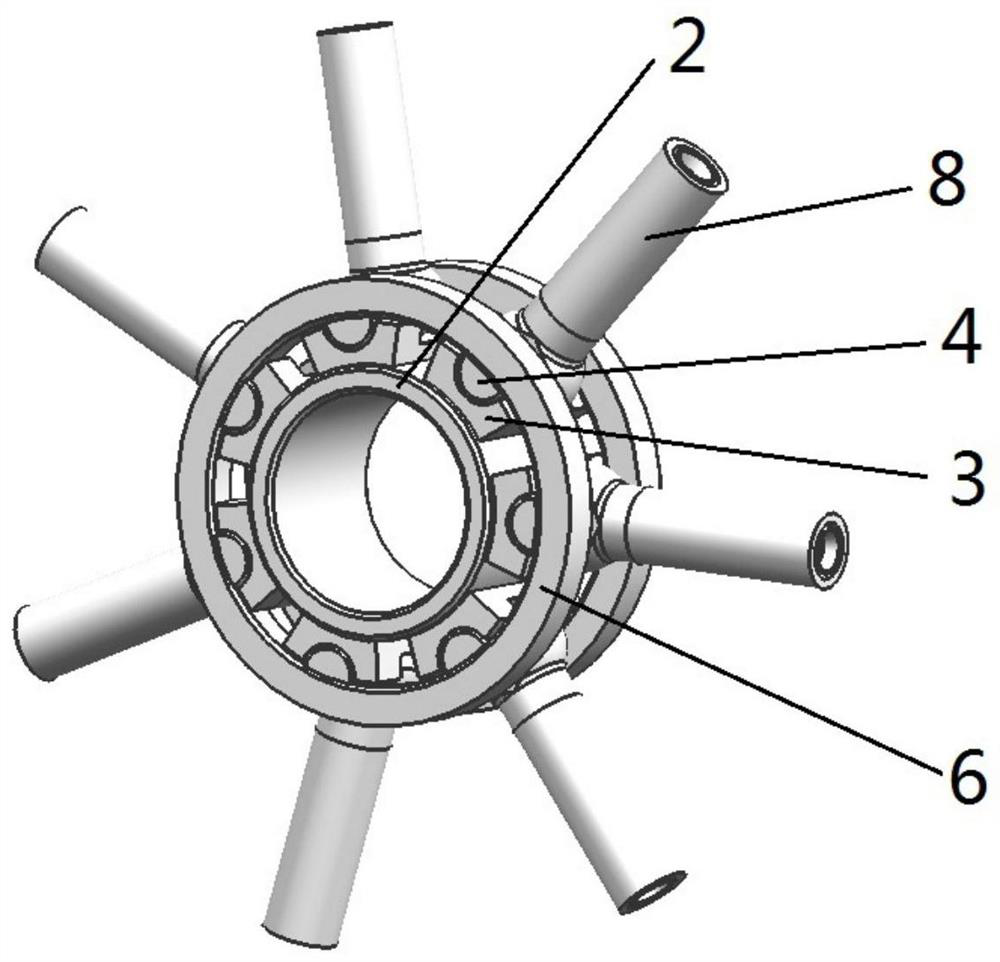

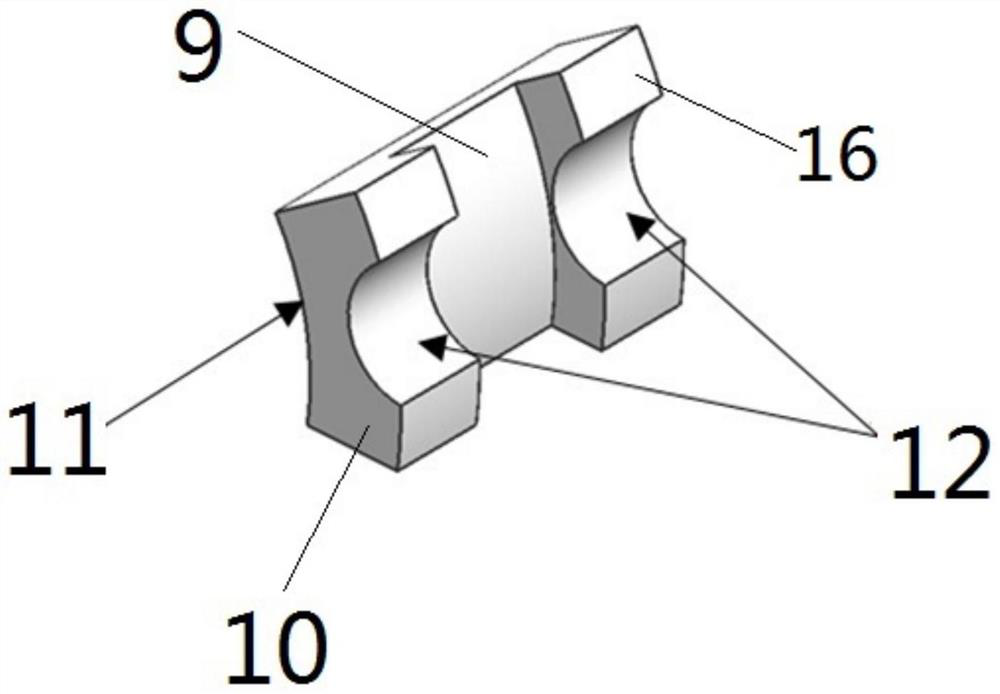

[0027] The lower end surface 11 of the shaft pad is a circular arc surface, and the lower end surface of the shaft pad matches the shape of the outer ring of the bearing of the cam 7. The upper end surface 9 of the shaft pad protrudes to form two symmetrical support platforms 10. The pin shaft The two ends are respectively supported on two symmetrical support platforms; the connecting end of the plunger is rotationally connected with the middle part of the pin shaft; a plunger 5, a pin shaft 4 and a shaft pad 3 form a plunger assembly;

[0028] A plurality of plunger assembly rings are arranged on the outer ring of the cam bearing, and the inner ring surface of the collar and the outer ring of the cam bearing radially limit the support platforms and / or pin ends of all plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com