countershaft automatic transmission

A technology for transmissions and countershafts, applied in vehicle gearboxes, transmission components, transmissions, etc., can solve problems such as large spin loss, affecting overall efficiency, and low fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The following description is merely exemplary in nature and is not intended to limit the disclosure, application, or use.

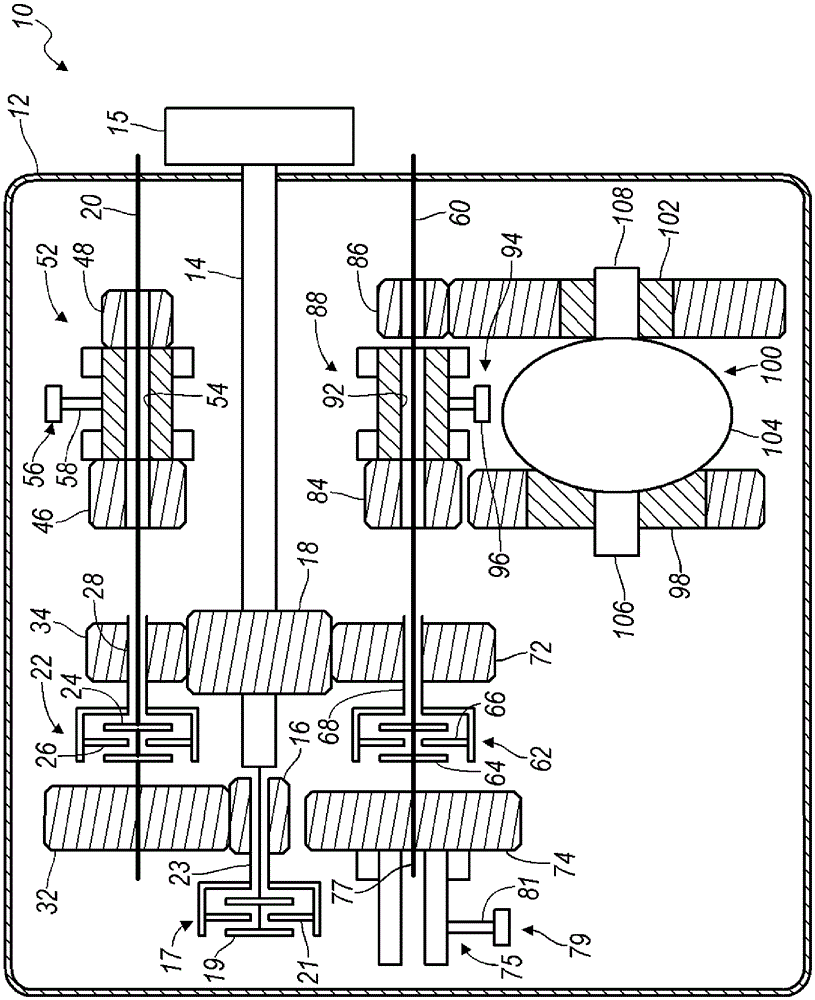

[0093] refer to figure 1 , a five-speed transmission is shown and generally designated by the reference number 10 . The five-speed dual clutch transmission 10 includes a housing 12 having various holes, openings, flanges and features that receive, position, support and protect the components of the transmission 10 . The housing 12 rotatably supports an input shaft 14 . Input shaft 14 is coupled at one end to flywheel damper assembly 15 . The flywheel damper assembly 15 receives input torque from a prime mover (not shown), such as an internal combustion engine, a hybrid engine, or an electric motor. The input shaft 14 is coupled at the opposite end to a launch clutch 17 . Launch clutch 17 includes a plurality of first clutch plates or discs 19 coupled to first shaft 14 for rotation therewith. A plurality of second clutch plates or discs 21 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com