Rolling bearing comprising three concentric rings

A technology of rolling bearings and rolling elements, applied in rolling contact bearings, roller bearings, bearings in rotating motion, etc., can solve problems such as increasing the bearing width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

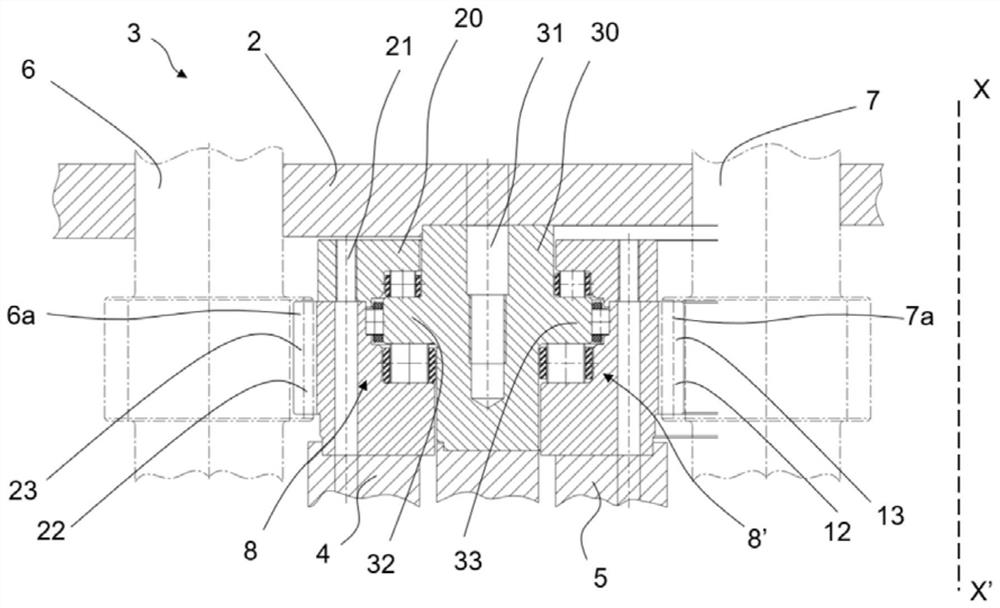

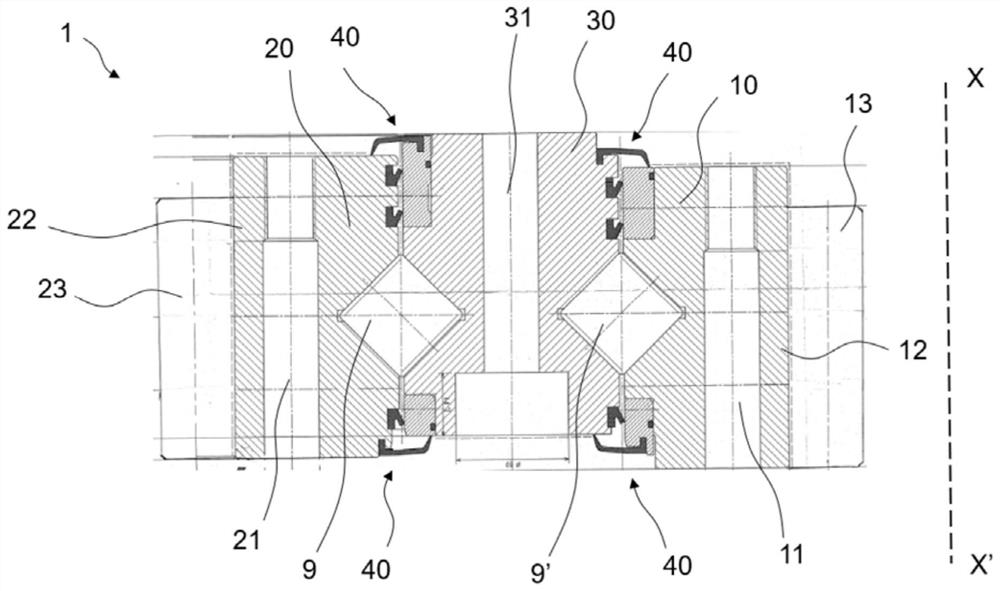

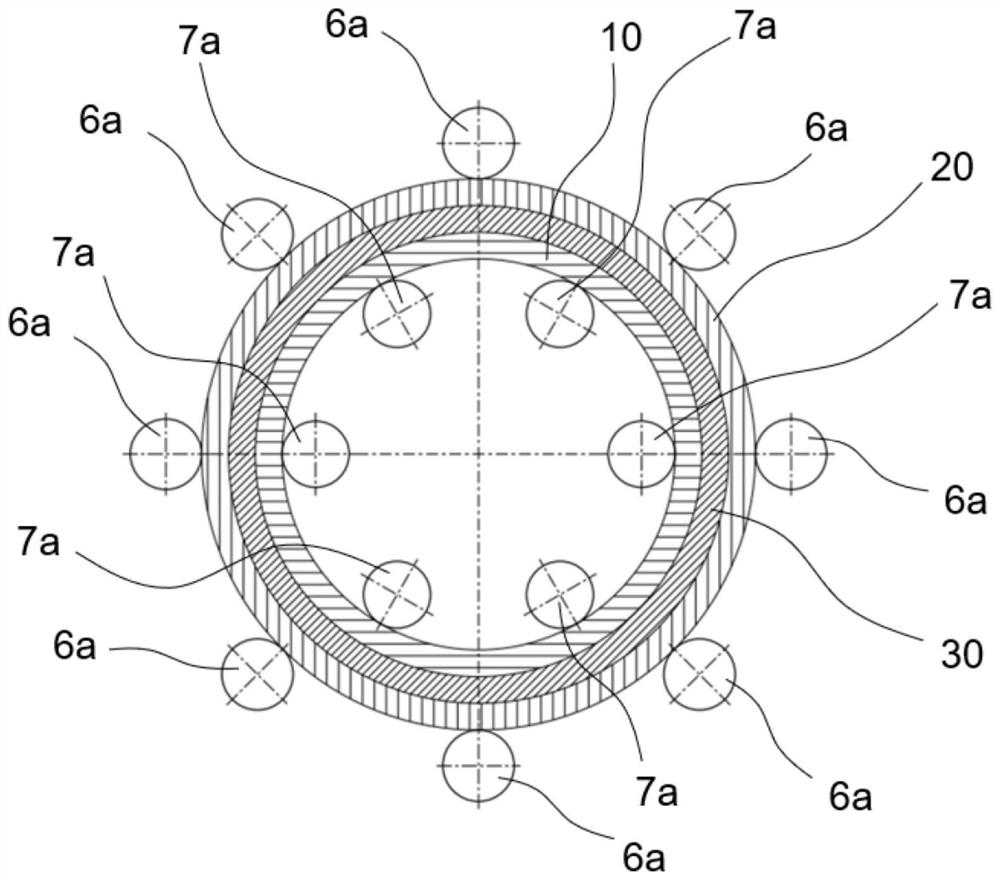

[0049] Figure 1 to Figure 3 A rolling bearing 1 comprising an inner ring 10 , an outer ring 20 and an intermediate ring 30 is shown. These three rings are arranged concentrically around the longitudinal axis XX'. The intermediate ring 30 is disposed between the inner ring and the outer ring in the radial direction.

[0050] At least one row of rolling elements is disposed between the outer ring and the middle ring, and at least one row of rolling elements is disposed between the inner ring and the middle ring.

[0051] The intermediate ring comprises a plurality of attachment means 31 for fixing the bearing to the frame 2 of the machine 3 .

[0052] The outer ring comprises a plurality of attachment means 21 for fixing the first machine element 4 to the bearing.

[0053] The outer ring comprises a radially outer peripheral portion 22 on which geartoothing 23 is arranged.

[0054] The inner ring comprises a plurality of attachment means 11 for fixing the second machine ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com