Anti-icing material, preparation method and application thereof

A functional material and anti-icing technology, which is applied in the field of chemical materials and can solve the problems of easy wear and applicable temperature range of materials, poor performance of anti-icing materials, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of oil gel anti-icing material

[0032] At room temperature, mix the purchased commercial polydimethylsiloxane prepolymer and cross-linking agent at a mass ratio of 10:1, stir evenly, centrifuge at 4000r / min for 5min to remove bubbles, and then drain in a vacuum atmosphere at room temperature Air for 30 minutes to remove bubbles in the mixed solution, then gently pour the mixed solution into a clean and dry glass petri dish, calibrate the level, and cure overnight at 80°C to make it fully crosslinked into an elastic silica gel PDMS.

[0033] Cut the prepared PDMS into a suitable size, immerse it in molten paraffin and swell for 5 hours, take out the swollen PDMS, the oil gel, and let it cool at room temperature, then carefully remove the oil gel from the molten liquid with tweezers and lens cleaning paper. Bring out the paraffin for use.

[0034] Other paraffin swellable cross-linked network polymers can also be used to prepare oil gels.

Embodiment 2

[0035] Example 2 Swelling and slow release of alkane molecules in oil gel

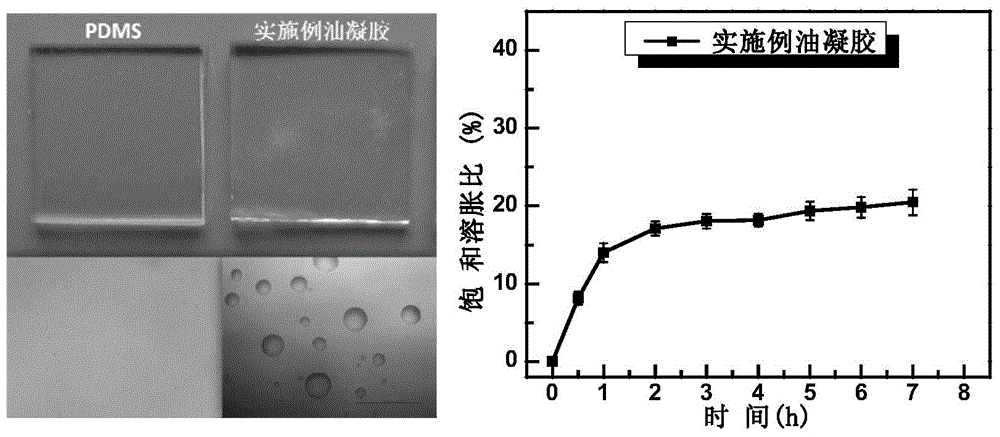

[0036] Such as figure 1 The cured PDMS prepared in the embodiment is an elastic transparent solid, and the paraffin-swollen PDMS is a transparent color. PDMS is immersed in molten paraffin, and it has reached half-saturation swelling rate quickly within 0.5h, and then slowly reaches swelling saturation in about 4~5h, saturated swelling ratio is 20.5%, and PDMS cross-linked network absorbs 20.5% of its own mass. Of paraffin.

[0037] The cross-linked network can hold more solvent at high temperature, and the capacity of the solvent is reduced when the temperature is lowered, causing the solvent to squeeze out of the cross-linked network structure. The slow-release surface driven by osmotic pressure forms a liquid film layer on which there are scattered droplets. AFM (tapping mode) shows that the sample surface is as flat as PDMS.

Embodiment 3

[0038] Example 3 DSC characterizes the glass transition temperature of paraffin wax

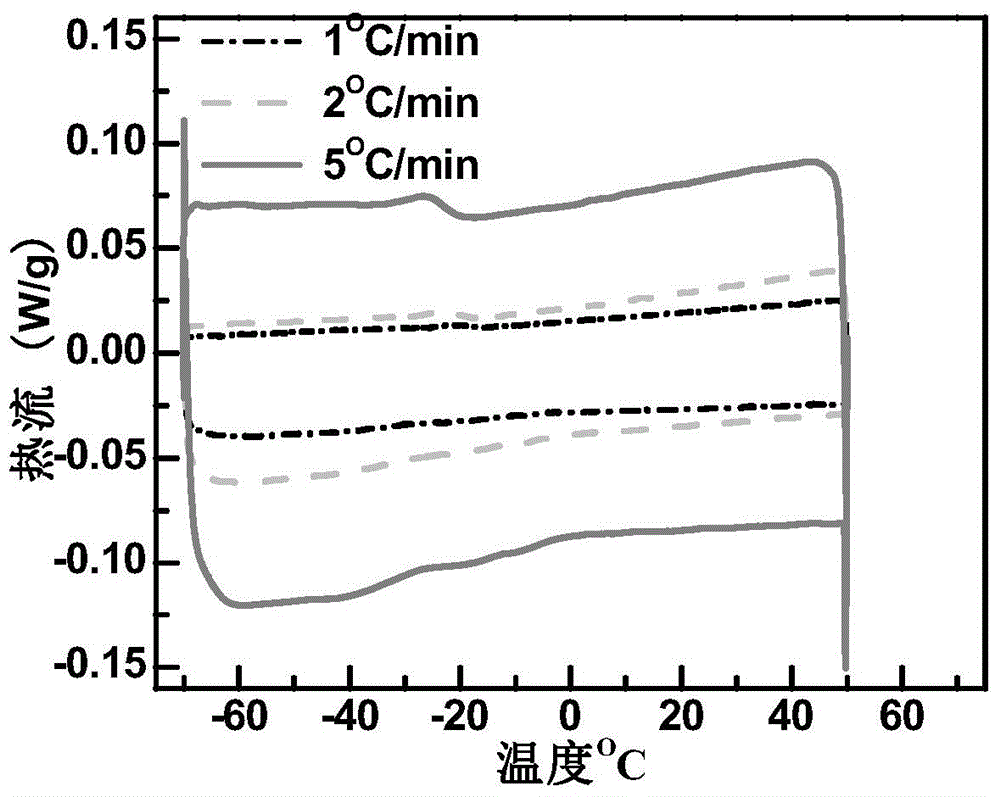

[0039] Such as figure 2 , For paraffin body phase differential scanning calorimeter (Differential Scanning Calorimeter, DSC) test, at 1℃ / min rate temperature, there is no obvious exothermic peak and endothermic peak, faster at 2℃ / min and 5℃ / min The temperature rate of -20℃ shows an exothermic step change, and the endothermic process is still a gradual change, indicating that the paraffin wax exhibits a glass transition during the temperature change, no phase change occurs, and the enthalpy change is very low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com