Automatic detecting and mistake-proofing method and device thereof based on Renishaw probe

A Renishaw probe and automatic detection technology, used in measuring/indicating equipment, metal processing mechanical parts, metal processing, etc., can solve problems such as attenuation of machine tool processing accuracy, quality problems, economic losses, etc. Short time and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention is applicable to any three-axis or multi-axis machine tool with detection function. The tool verification device does not involve the algorithms of various machine tools, but it needs to have a certain understanding of the usage of the control system and interpolation instructions and the working principle of the probe, and can use variables To write a measurement macro program, if the characteristic features of a multi-axis machine tool are developed, an in-depth study of the kinematics of the machine tool is required, and the method of the present invention does not require any research for the user.

[0028] The following is further elaborated with examples:

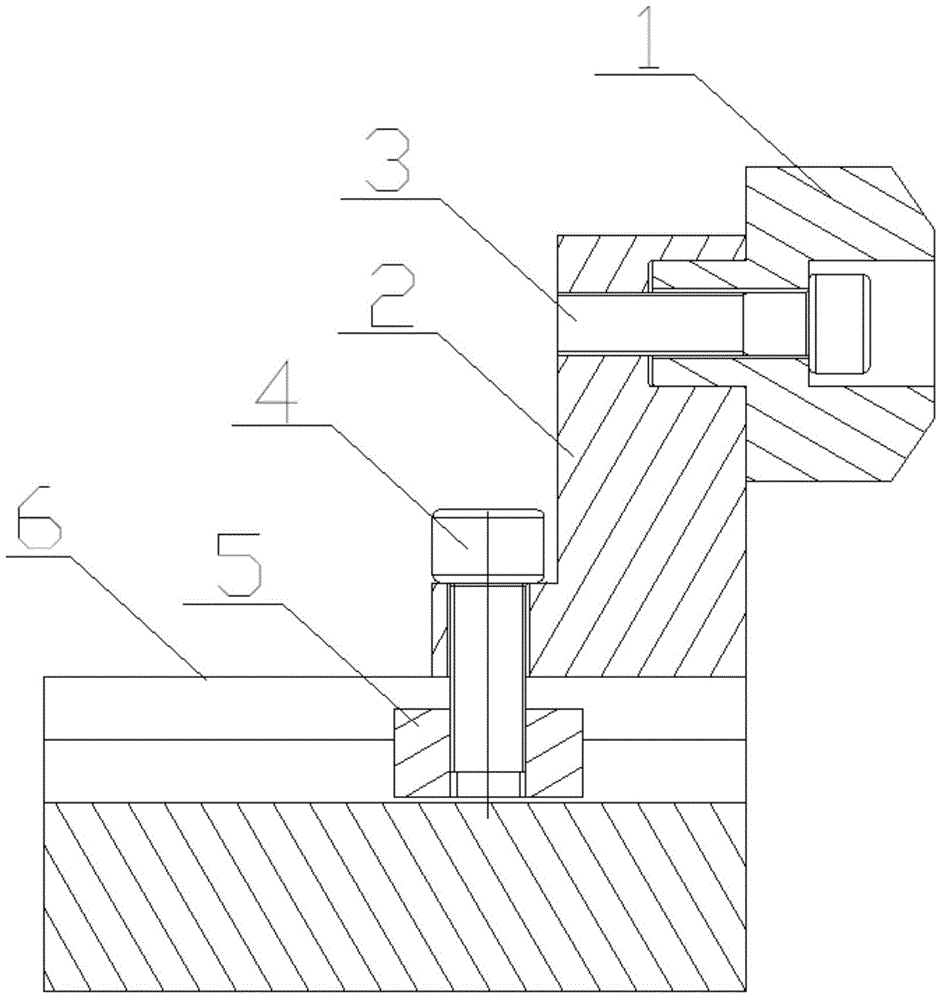

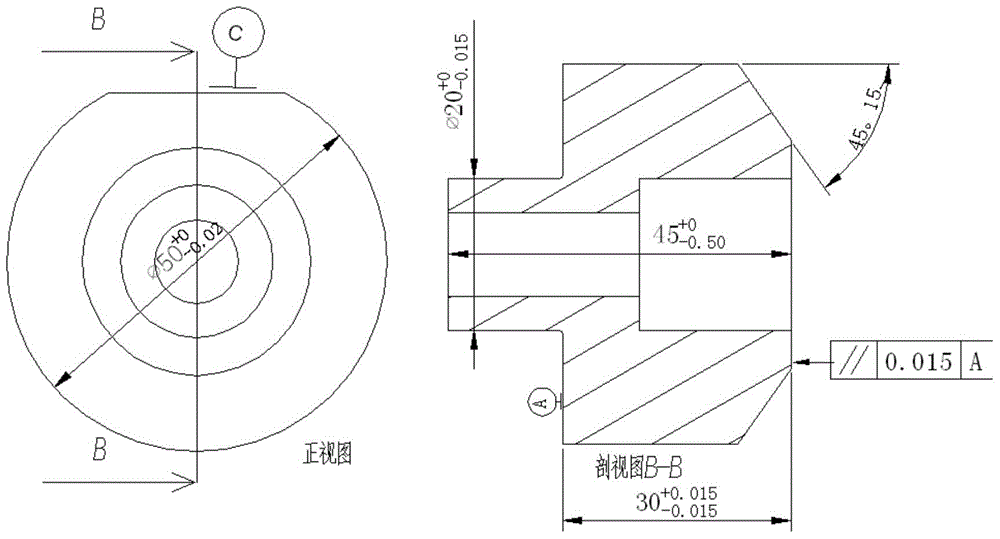

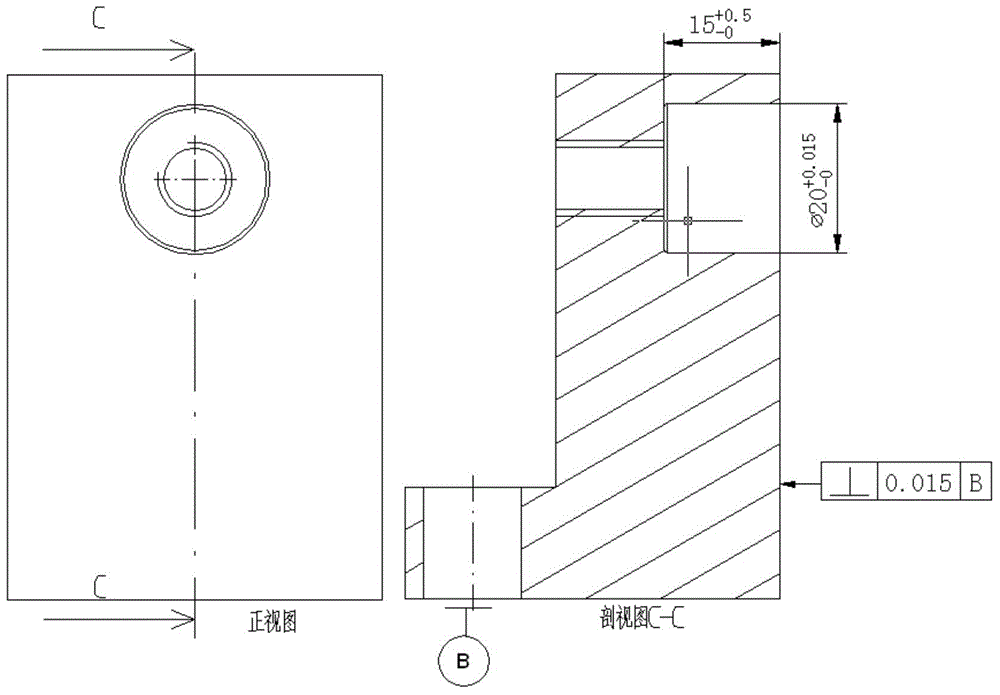

[0029] An automatic detection and error prevention device based on a Renishaw probe, an automatic detection and error prevention device based on a Renishaw probe, including a tool setting block 1, a base 2 and a T-shaped base 5, wherein the tool setting block 1 is passed through a bolt 3 Fastened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com