Method and tooling for electric spark machining of internal thread of hard alloy product

A technology of hard alloy and processing method, which is applied in the direction of electric processing equipment, metal processing equipment, accessory devices, etc., and can solve the problems of small effective working area of electrodes, affecting the quality of internal threads, and difficulty in ensuring the size and shape accuracy of internal threads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for machining internal threads of cemented carbide products by electric discharge of the present invention:

[0040] Carbide grade is: YG8

[0041] Product processing requirements: The internal thread specification of the product is M8 right-handed thread, the major diameter of M8 internal thread is 8mm, the minor diameter of M8 internal thread is 6.75mm, the middle diameter is 7mm, the minor diameter of one-half is 3.375mm, and the pitch is 1.25 mm, the length of the threaded section is 10mm.

[0042] The processing steps are as follows:

[0043] S1. Threaded bottom hole processing, a threaded bottom hole with a diameter of 6.75 mm is processed on the cemented carbide product 5 .

[0044] S2. tooling production, including making the electrode 4 for discharging the cemented carbide product 5 and the screw clamping device for clamping the cemented carbide product 5, the specific steps are as follows:

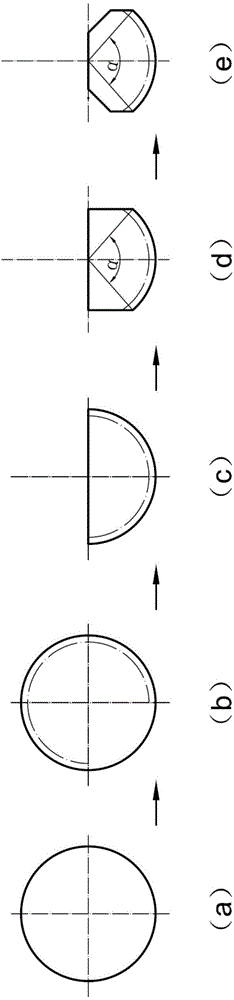

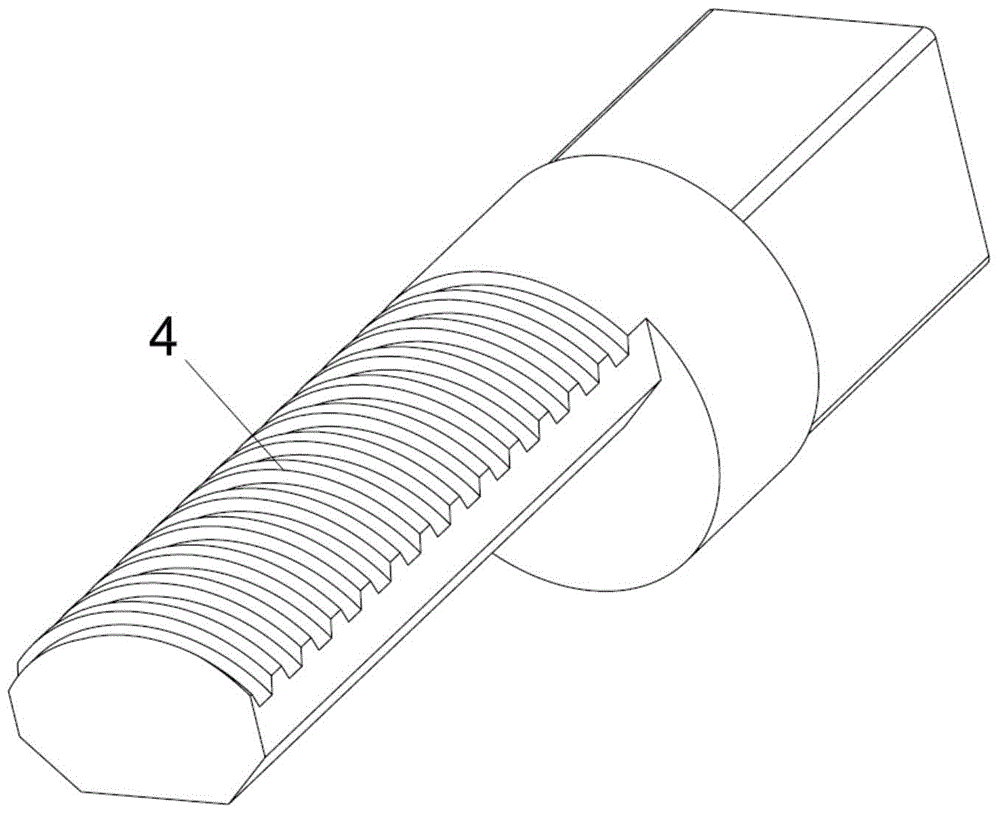

[0045] S21. Fabrication of electrode 4, refer to figure ...

Embodiment 2

[0057] A method for machining internal threads of cemented carbide products by electric discharge of the present invention:

[0058] Carbide grade: YN10

[0059] Product processing requirements: The internal thread specification of the product is M10 left-handed thread, the major diameter of M10 internal thread is 10mm, the minor diameter of M10 internal thread is 8.376mm, the middle diameter is 9.026mm, the minor diameter of one-half is 4.188mm, and the pitch is 1.5 mm, the thread length is 22.5mm.

[0060] The processing steps are as follows:

[0061] S1. Threaded bottom hole processing, a threaded bottom hole with a diameter of 8.376 mm is processed on the cemented carbide product 5 .

[0062] S2. tooling production, including making the electrode 4 for discharging the cemented carbide product 5 and the screw clamping device for clamping the cemented carbide product 5, the specific steps are as follows:

[0063] S21. Fabrication of electrode 4, refer to figure 1 , fig...

Embodiment 3

[0074] A method for machining internal threads of cemented carbide products by electric discharge of the present invention:

[0075] Carbide grade is: YG20C

[0076] Product processing requirements: The internal thread specification of the product is M20 right-handed thread, the major diameter of M20 internal thread is 20mm, the minor diameter of M20 internal thread is 17.294mm, the middle diameter is 18.376mm, the minor diameter of one-half is 8.647mm, and the pitch is 2.5mm, the length of the threaded section is 32.5mm.

[0077] The processing steps are as follows:

[0078] S1. Threaded bottom hole processing, a threaded bottom hole with a diameter of 17.294 mm is processed on the cemented carbide product 5 .

[0079] S2. tooling production, including making the electrode 4 for discharging the cemented carbide product 5 and the screw clamping device for clamping the cemented carbide product 5, the specific steps are as follows:

[0080] S21. Fabrication of electrode 4, refe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com