A bimodal distribution nano-silver paste used as thermal interface material and preparation method thereof

A thermal interface material, bimodal distribution technology, used in semiconductor/solid-state device manufacturing, circuits, electrical solid-state devices, etc., can solve problems such as device failure, and achieve uniform size, high thermal conductivity, and stable and reliable process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

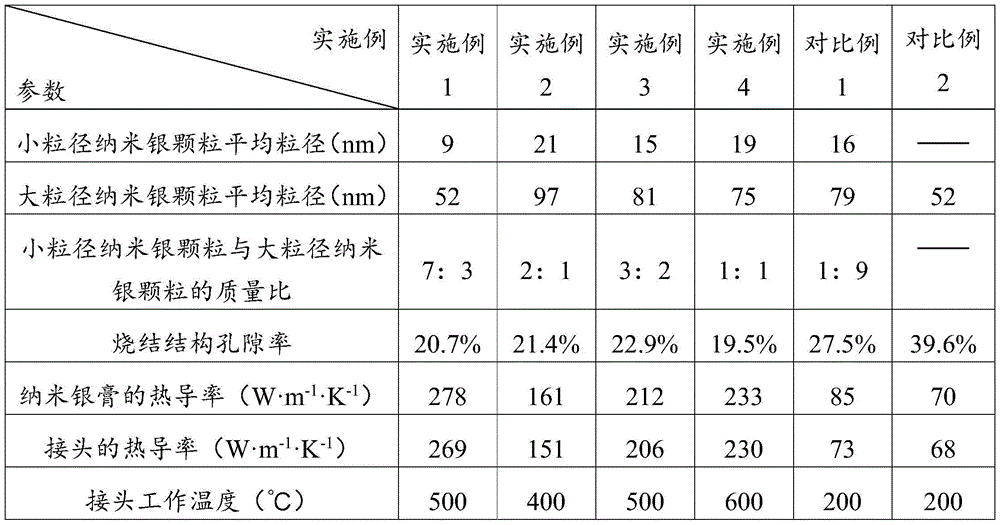

[0036] Example 1 Preparation of a bimodal distribution nano-silver paste used as a thermal interface material

[0037] Mix small-size nano-silver particles (average particle size 9nm), large-size nano-silver particles (average particle size 52nm) and ultrapure water at a mass ratio of 7:3:50, mechanically stir for 50 minutes, and ultrasonically disperse in ice water 40min, and then centrifuged at a speed of 4000rpm for 15min again to remove the upper layer solution to obtain the bimodal distribution nano-silver paste precipitated at the bottom.

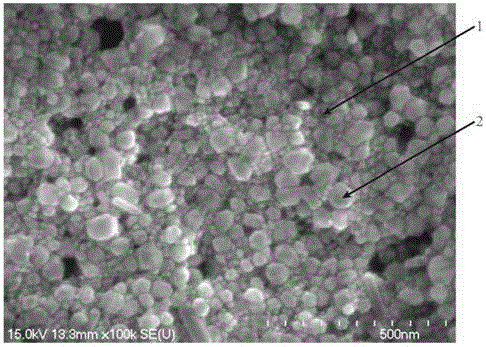

[0038] The SEM picture of the bimodal distribution nano-silver paste prepared by mixing is as follows figure 1 shown.

[0039] Apply bimodal distribution nano-silver paste on the surface of the interconnection between SiC chip and Cu substrate to form a sandwich structure of SiC chip / bimodal distribution nano-silver paste / Cu substrate, and place it on a heating plate at a temperature of 200°C for 20 minutes to form a sintered joint ...

Embodiment 2

[0040] Example 2 Preparation of a bimodal distribution nano-silver paste used as a thermal interface material

[0041] Mix small-size nano-silver particles (average particle size 21nm), large-size nano-silver particles (average particle size 117nm) and ultrapure water at a mass ratio of 2:1:12, mechanically stir for 30 minutes, and ultrasonically disperse in ice water 40min, and then centrifuged at a speed of 3000rpm for 10min again to remove the upper layer solution to obtain the bimodal distribution nano-silver paste precipitated at the bottom.

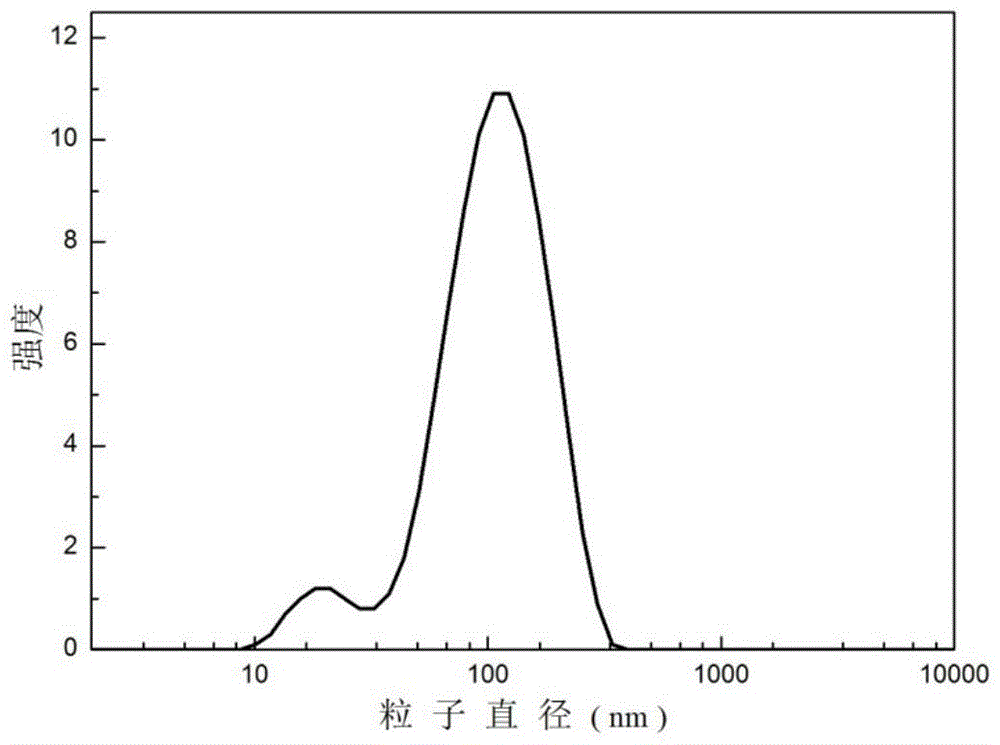

[0042] The laser particle size analyzer scanning image of the prepared uniformly mixed bimodal distribution nano-silver paste is as follows: figure 2 shown.

[0043] Apply bimodal distribution nano-silver paste on the surface of the interconnection between SiC chip and Cu substrate to form a sandwich structure of SiC chip / bimodal distribution nano-silver paste / Cu substrate, and place it on a heating plate at a temperature of 150°C...

Embodiment 3

[0044] Example 3 Preparation of a bimodal distribution nano-silver paste used as a thermal interface material

[0045] Mix small-size nano-silver particles (average particle size 15nm), large-size nano-silver particles (average particle size 81nm) and ultrapure water at a mass ratio of 3:2:30, mechanically stir for 30 minutes, and ultrasonically disperse in ice water 30min, and then centrifuged at a speed of 3000rpm for 20min again to remove the upper layer solution to obtain the bimodal distribution nano-silver paste precipitated at the bottom.

[0046] Apply bimodal distribution nano-silver paste on the surface of the interconnection between SiC chip and Cu substrate to form a sandwich structure of SiC chip / bimodal distribution nano-silver paste / Cu substrate, and place it on a heating plate at a temperature of 200°C for 30 minutes to form a sintered joint .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com