Device and method for purifying in treatment of volatile gas of petrochemical coke cooling water tank

A technology of purification device and cold coke water, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of complex toxic and harmful gases, unstable gas volume and flow rate, and difficult processing, so as to save processing costs, Easy to operate and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

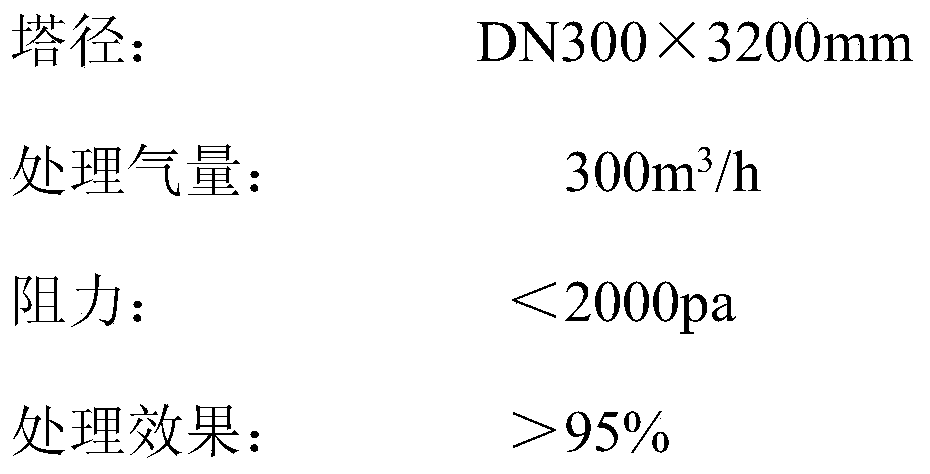

[0015] like figure 1 As shown, the purification device for volatile gas treatment of petrochemical cold coke water tanks includes a buffer tank 1, a condenser 2, a first ejector 3, a first swirl absorption tower 4, a spray head 5, and a second swirl Absorption tower 6, second ejector 7, exhaust cylinder 8, second circulation pump 9, second circulation tank 10, first circulation pump 11, first circulation tank 12, air guide pipe 14 and absorbent circulation pipe 13, which The structural feature is that the top of the buffer tank 1 is connected to the lower part of the condenser 2, the upper part of the condenser 2 is connected to the first ejector 3, and the bottom of the first ejector 3 is connected to the bottom of the first cyclone absorption tower 4 and the first circulation tank respectively. 12, the top of the first circulation tank 12 is connected to the lower side wall of the first cyclone absorption tower 4 through the air guide pipe 14, and the spray head 5 in the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com