Gear and method for producing same

A manufacturing method and technology of gears, applied in the directions of belts/chains/gears, gear teeth, components with teeth, etc., can solve problems such as stress increase and damage, and achieve the effect of improving long-term durability characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Embodiments of the present invention will be described below with reference to the accompanying drawings.

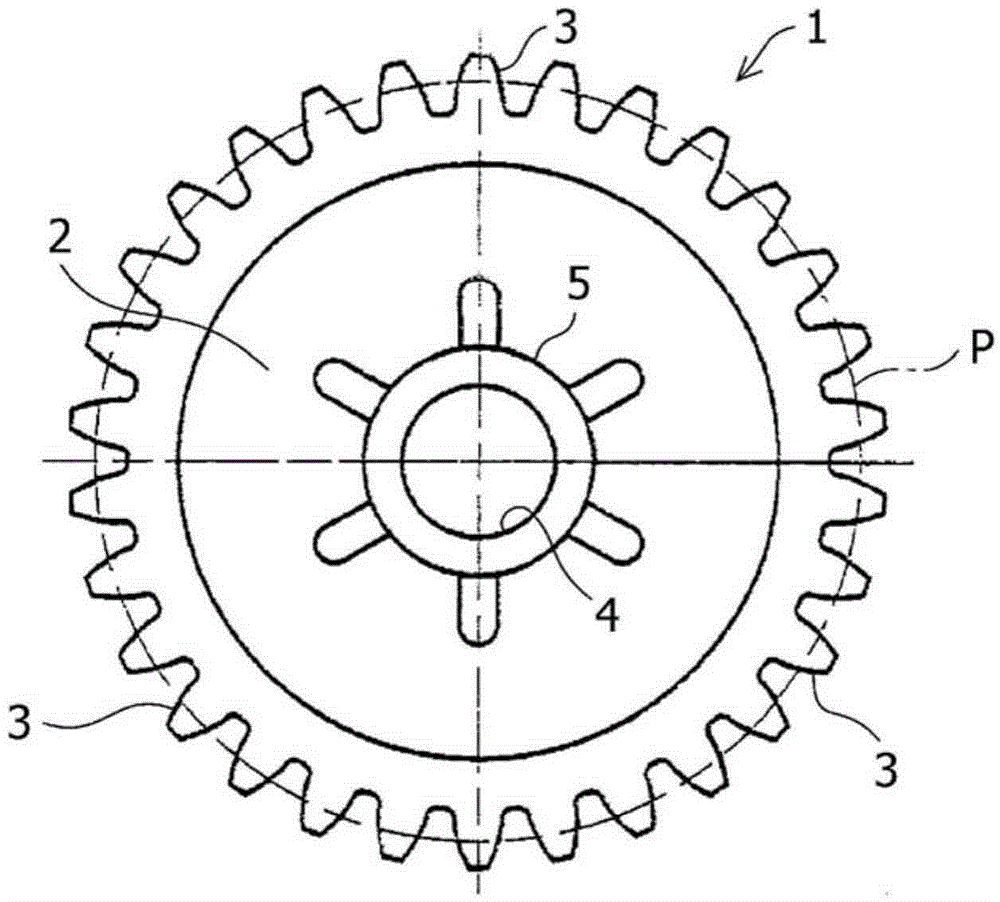

[0054] figure 1 It is a front view showing the overall shape of the gear of the present invention. The gear has a plurality of teeth and transmits rotational motion between the two shafts by meshing with the teeth of the counterpart gear. For example, it is widely used in power transmission mechanisms of automobiles, precision machinery, industrial machinery and their parts.

[0055] exist figure 1 In the gear 1, a plurality of teeth 3, 3... are formed on the outer peripheral side of the substantially disc-shaped web 2, and a boss 5 is formed at the center of the web 2. The shaft hole 4 where the shaft is fixed transmits the rotary motion between the two shafts. In addition, symbol P represents the pitch circle of the gear 1 .

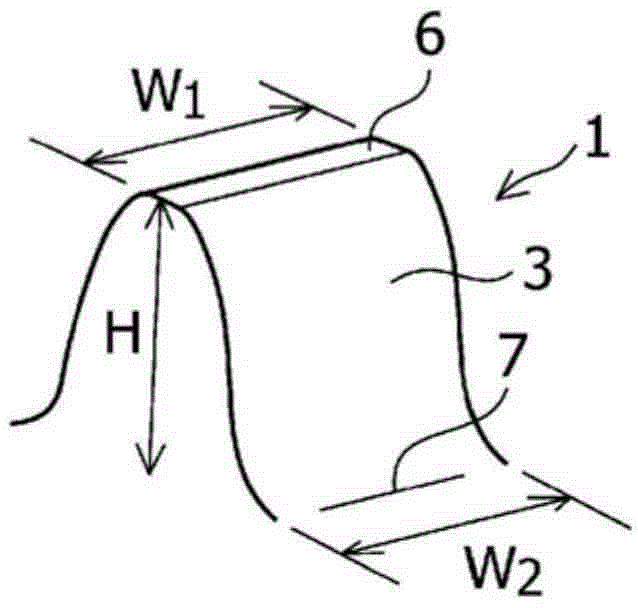

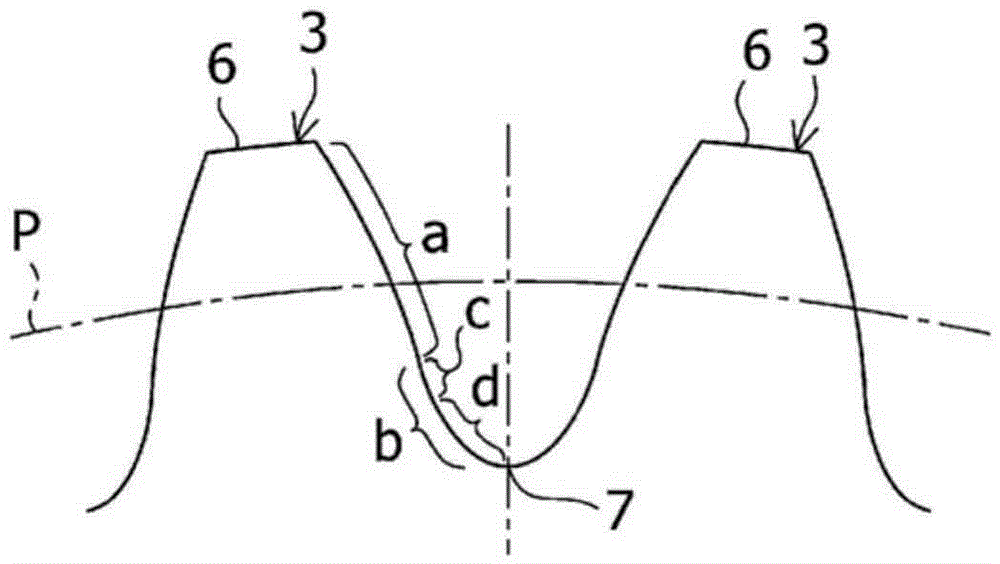

[0056] generally as figure 2 As shown, the tooth 3 of the gear 1 is formed as a tooth shape of a standard gear having a tooth surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com