High-performance solar battery module

A solar cell, high-performance technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as affecting the elongation of EVA, and achieve the effect of solving heat dissipation, ensuring efficiency, and avoiding the decrease of insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

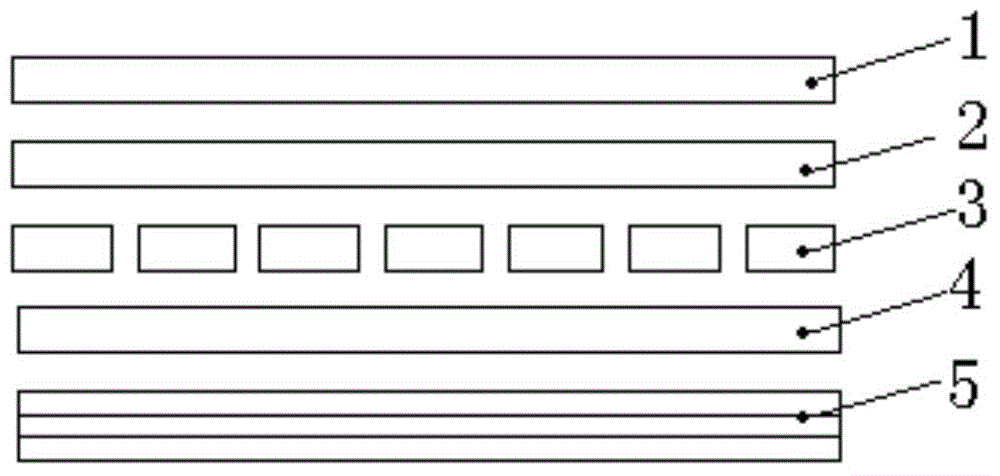

[0011] figure 1 As shown, it involves a high-performance solar cell module, including an ultra-clear glass layer 1 arranged on the first layer, a high-permeability EVA film layer 2 arranged on the second layer, and a cell sheet layer 3 arranged on the third layer, The low thermal conductivity EVA film layer 4 is arranged on the fourth layer, and the thermal conductivity backplane layer 5 is arranged on the fifth layer.

[0012] Wherein, the low thermal conductivity EVA film layer 4 is composed of the following components in mass percentage: EVA 80%, ZnO masterbatch 20%, peroxide crosslinking agent 1.2-1.5%, antiaging agent 1%, and crosslinking agent Synthetic Accelerator 1%.

[0013] During manufacture, the materials of the above-mentioned components are uniformly mixed, and the film is formed by casting or calendering process, and the thickness of the obtained low thermal conductivity EVA film layer 4 is between 0.35-0.4mm. Volume resistivity of the low thermal conductivity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com