Mercury-containing metal halide lamp, metal halide pill and preparation method of metal halide pill

A technology of metal halide pellets and metal halide lamps, which is applied in the field of lighting and optoelectronics, can solve the problems of poor color temperature stability of mercury-containing metal halide lamps and corrosion of arc tubes, and achieve good color rendering index, avoid corrosion, and stabilize color temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

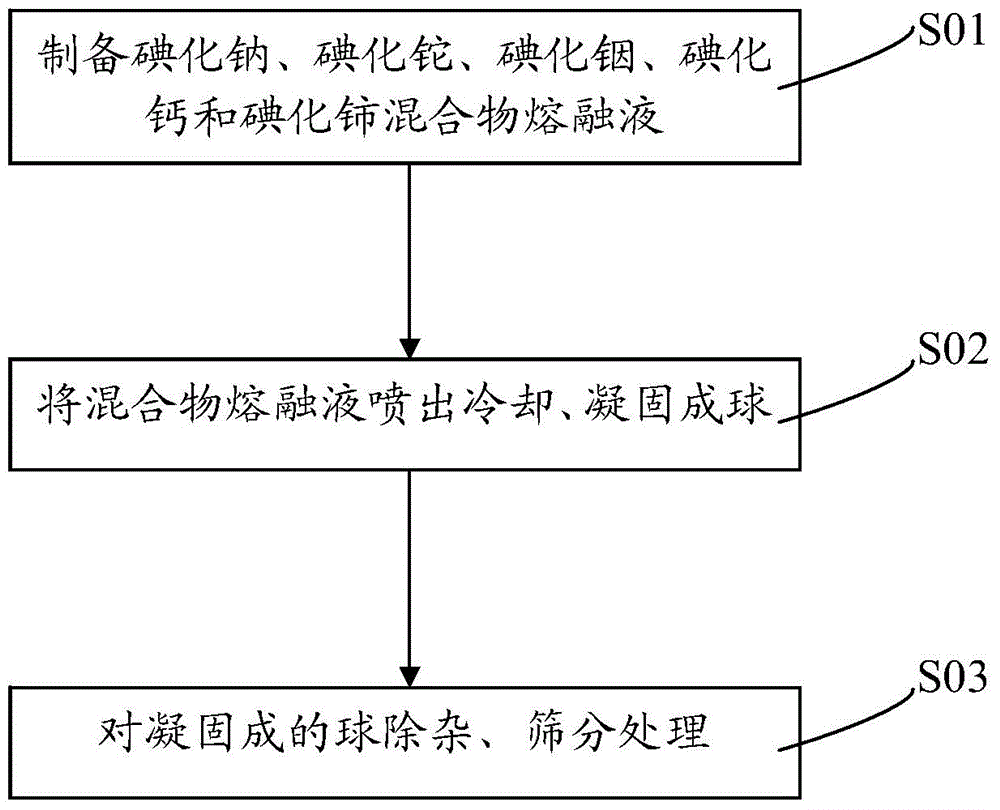

[0020] Correspondingly, the embodiment of the present invention also provides a method for preparing the metal halide pellets of the mercury-containing metal halide lamp in the above embodiment, the process of the method is as follows figure 1 shown. The method comprises the steps of:

[0021] S01. Preparation of sodium iodide, thallium iodide, indium iodide, calcium iodide and cerium iodide mixture melt: sodium iodide, thallium iodide, indium iodide, calcium iodide and cerium iodide gold halide according to (0.3~0.8):(0.01~0.05):(2.0×10 -3 ~5.0×10 -3 ):(0.1~0.4):(1.0×10 -3 ~6.0×10 -3 ) are mixed, heated to melt in an oxygen-free atmosphere to obtain a melt;

[0022] S02. Spray the molten mixture to cool and solidify into balls: spray the molten liquid prepared in step S01 into an atmosphere protected by a high-purity inert gas, and make liquid beads naturally form after spraying under the protection of the high-purity inert gas Cool in the atmosphere and solidify into b...

Embodiment 1

[0053] A metal halide pellet of a mercury-containing metal halide lamp, comprising sodium iodide, thallium iodide, indium iodide, calcium iodide and cerium iodide, sodium, thallium, indium, calcium and The molar ratio of cerium is 0.3:0.01:2.0×10 -3 :0.1:1.0×10 -3 .

[0054] The preparation method of the metal halide pill of this mercury-containing metal halide lamp is as follows:

[0055] Mix the sodium iodide, thallium iodide, indium iodide, calcium iodide and cerium iodide gold halide contained in the above-mentioned gold halide pellets according to the proportion, form a mixture and place it in a quartz container with a nozzle at 120 ° C Under pre-vacuum treatment for 30 minutes, then slowly heated to 730 ° C to melt the mixture, stirred for 40 minutes, and the molten mixture was ejected from the nozzle at a speed of 40 cm / s. Cool quickly and solidify into balls. Then the obtained product is further removed the trace impurities adsorbed on the surface of the ball under...

Embodiment 2

[0058] A metal halide pellet of a mercury-containing metal halide lamp, comprising sodium iodide, thallium iodide, indium iodide, calcium iodide and cerium iodide, sodium, thallium, indium, calcium and The molar ratio of cerium is 0.8:0.05:5.0×10 -3 :0.4:6.0×10 -3 .

[0059] The preparation method of the metal halide pill of this mercury-containing metal halide lamp is as follows:

[0060] Mix the sodium iodide, thallium iodide, indium iodide, calcium iodide and cerium iodide gold halide contained in the above-mentioned gold halide pellets according to the proportion, form a mixture and place it in a quartz container with a nozzle at 130 ° C Under vacuum for 50 minutes, then slowly heated to 750 ° C to melt the mixture, stirred for 30 minutes, and the molten mixture was ejected from the nozzle at a speed of 20 cm / s. Cool quickly and solidify into balls. Then the obtained product is further removed the trace impurities adsorbed on the surface of the ball under the high vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Grain weight | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com