Laser image detection device and detection method for air preheater rotor deformation

An air preheater, image detection technology, applied in measurement devices, optical devices, instruments, etc., can solve problems affecting air leakage control effect, boiler maintenance and replacement, measurement result drift, etc., to improve effective running time and reliability. performance, easy installation and maintenance, and large measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

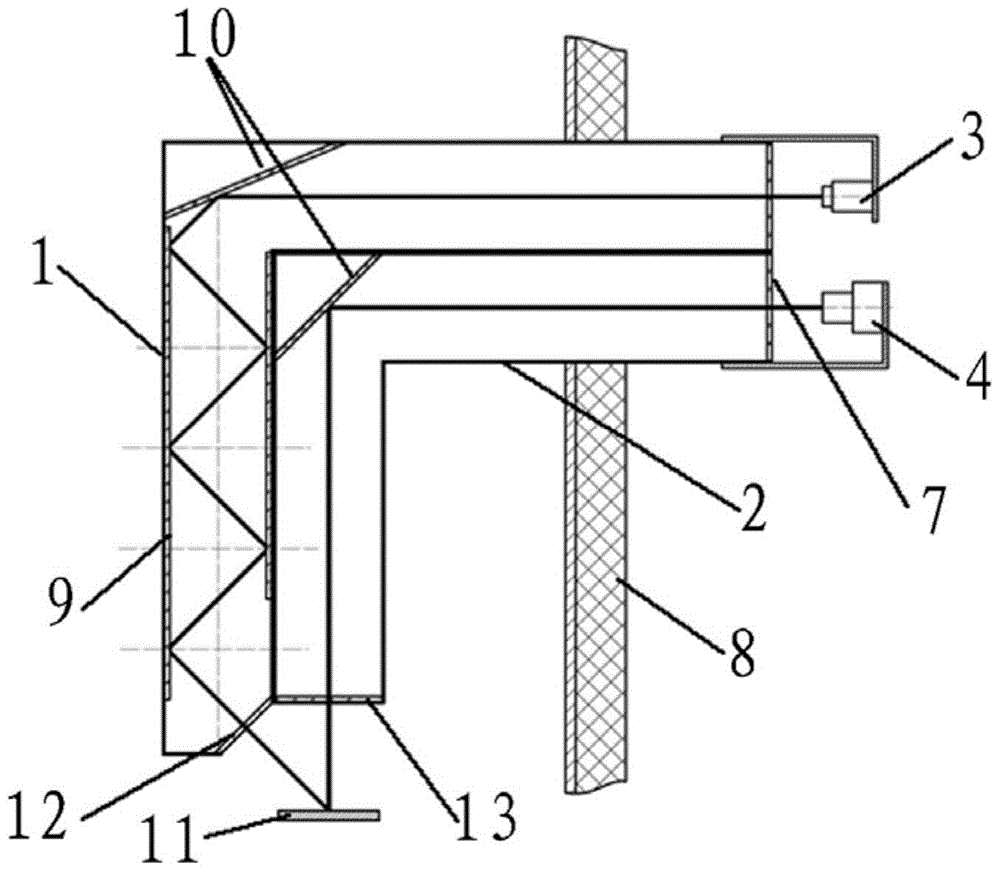

[0052] An embodiment of the present invention provides a laser image detection device for the deformation of the air preheater rotor, such as figure 1 As shown, the device includes: a first L-shaped channel 1, a second L-shaped channel 2, a laser emitter 3, and an image collector 4, the first L-shaped channel 1 is superimposed on the second L-shaped channel 2, And both are arranged horizontally, the inner wall of the vertical part of the first L-shaped channel 1 is relatively provided with a mirror 9, and the corners of the first L-shaped channel 1 and the second L-shaped channel 2 are provided with glass mirrors 10, The outlet of the first L-shaped passage 1 is provided with a first inner sealing glass 12 at an angle to the horizontal direction, and the entrance of the second L-shaped passage 2 is horizontally provided with a second inner sealing glass 13; An L-shaped channel 1 and a second L-shaped channel 2 are arranged above the rotor of the air preheater.

[0053] One en...

Embodiment 2

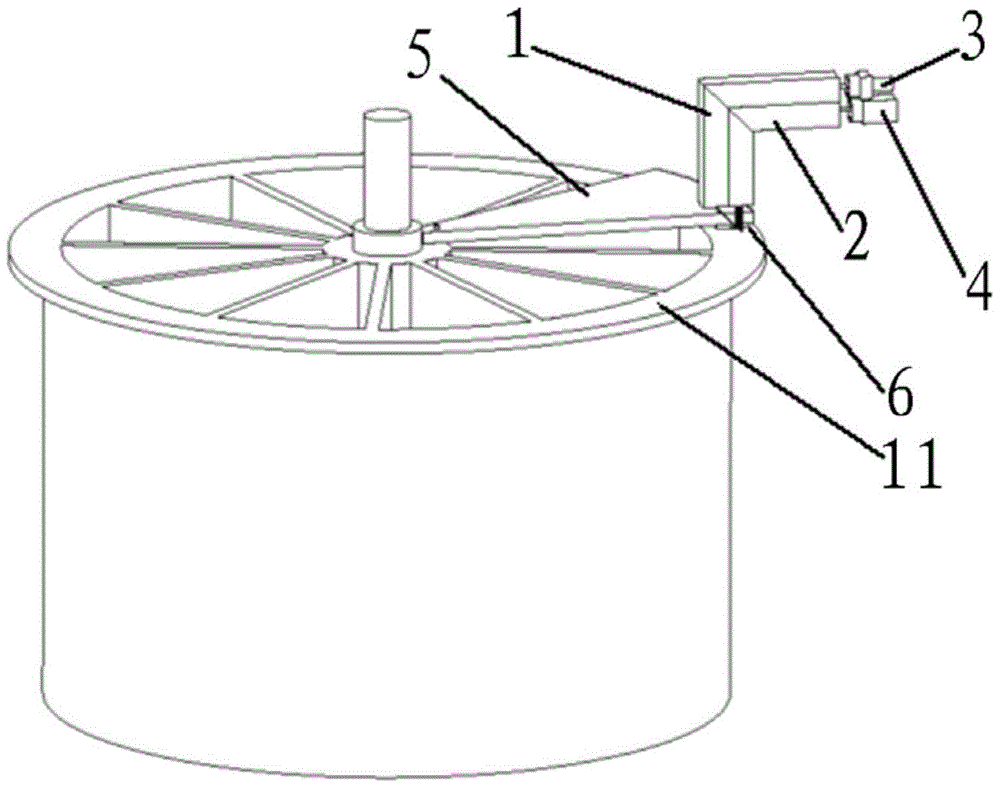

[0055] An embodiment of the present invention provides a laser image detection device for the deformation of the air preheater rotor, such as figure 1 , 2 As shown, the device includes: a first L-shaped channel 1, a second L-shaped channel 2, a laser emitter 3, and an image collector 4, the first L-shaped channel 1 is superimposed on the second L-shaped channel 2, And both are arranged horizontally, the inner wall of the vertical part of the first L-shaped channel 1 is relatively provided with a mirror 9, and the corners of the first L-shaped channel 1 and the second L-shaped channel 2 are provided with glass mirrors 10, The outlet of the first L-shaped passage 1 is provided with a first inner sealing glass 12 at an angle to the horizontal direction, and the entrance of the second L-shaped passage 2 is provided with a second inner sealing glass 13 horizontally; air preheating The fan-shaped plate 5 above the measuring reference plane 11 of the rotor rotor is provided with a p...

Embodiment 3

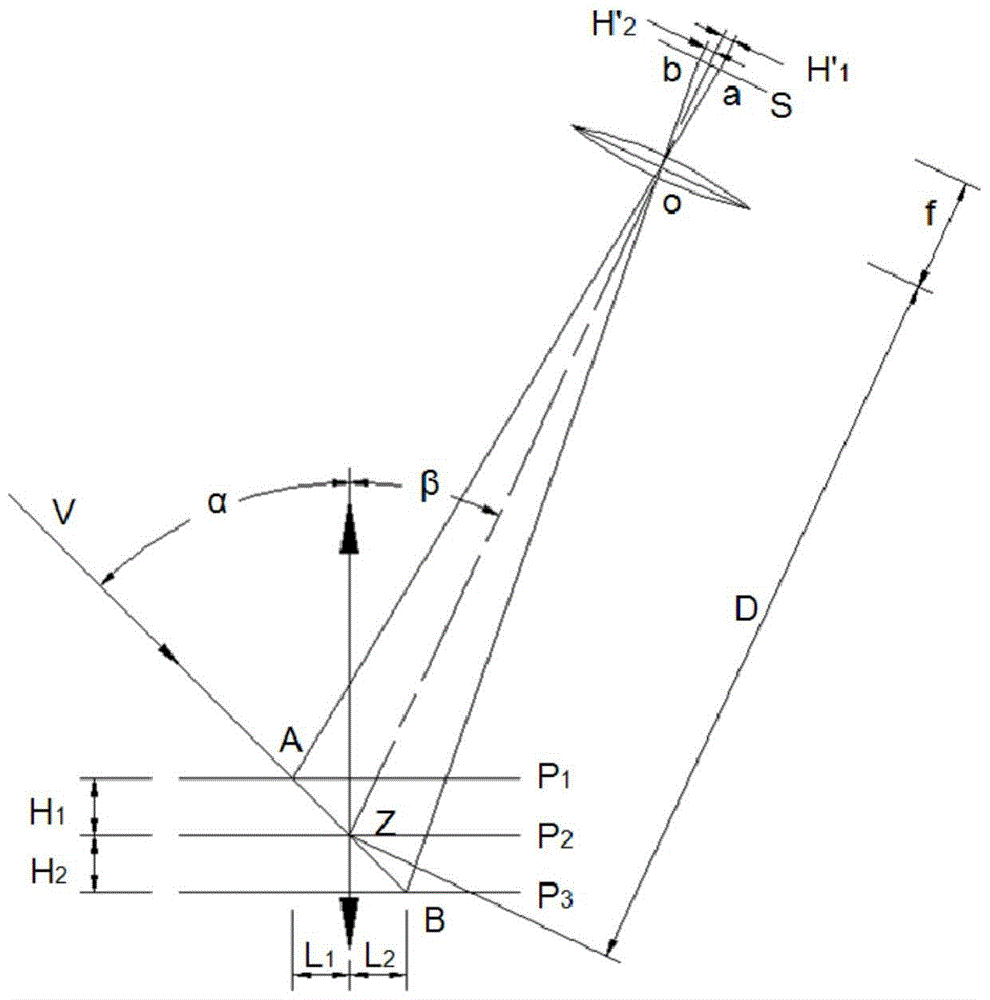

[0079] The embodiment of the present invention provides a laser image detection method for the deformation of the rotor of an air preheater. The method is as follows: the point-shaped laser beam emitted by the laser emitter 3 passes through the mirror surface at the inner corner of the first L-shaped channel 1 and the The specular reflection on the inner wall of the vertical part of the first L-shaped channel 1 is relatively arranged, so that the point-like laser beam is projected at an angle on the measurement reference plane 11 of the rotor of the air preheater to present a spot image, and the image collector 4 passes through the second L The specular reflection at the inner corner of the type channel 2 collects the spot images of the measurement reference plane 11 of the air preheater rotor at different positions, and obtains the absolute change of the air preheater rotor according to the spot images.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com