Immobilized enzyme screen reactor and application thereof

A technology of immobilized enzyme screens and immobilized enzymes, applied in the direction of enzyme production/bioreactors, biochemical instruments, biochemical equipment and methods, etc., can solve the problems of increased use costs, small particles, and reduced use efficiency, and achieve good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

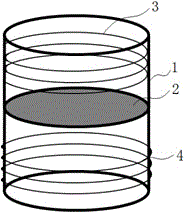

Embodiment 1

[0028] Inject 30.0L of 3M N-methyldiethanolamine solution into an 80.0L reactor storage tank, and spray it from the top into a 10.0L cylindrical stainless steel reactor at a rate of 10mL / min through a liquid circulation pump. The liquid flows back into the storage tank from the bottom of the kettle. The inner diameter of the stainless steel reactor is 10cm, and the height is 200cm. will contain 100% CO 2 The gas is passed into the bottom of the reaction kettle at a speed of 1.0mL / min, and reacts with N-methyldiethanolamine solution inside the reaction kettle for 1 hour, and 10mL of the reaction solution is taken from the bottom of the reaction kettle every 5min. The carbon dioxide absorption effect of the N-methyldiethanolamine solution was detected by measuring the pH value of the reaction solution. Two sets of experiments were carried out in parallel, and 5 layers of sieves filled with immobilized enzymes were evenly dispersed inside a group of reactors, and 10 g of immobi...

Embodiment 2

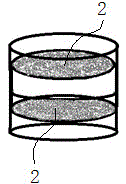

[0031] Inject 30.0L of 3M N-methyldiethanolamine solution into an 80.0L reactor storage tank, and spray it from the top into a 10.0L cylindrical stainless steel reactor at a rate of 10mL / min through a liquid circulation pump. The liquid flows back into the storage tank from the bottom of the kettle. The inner diameter of the stainless steel reaction kettle is 10cm, the height is 200cm, and the inner diameter of the kettle is filled with a porous inert filler with a diameter of 5mm. will contain 100% CO 2 The gas is passed into the bottom of the reaction kettle at a speed of 1.0mL / min, and reacts with N-methyldiethanolamine solution inside the reaction kettle for 1 hour, and 10mL of the reaction solution is taken from the bottom of the reaction kettle every 5min. The carbon dioxide absorption efficiency of the N-methyldiethanolamine solution is detected by the time required for the pH value of the reaction solution to change (from 9.3 to 8.0). After the reaction is over, the ...

Embodiment 3

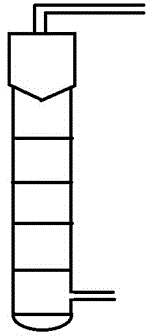

[0034] Spray 1.0L of aqueous solution with 6.5g of zinc powder and 6.5g of titanium dioxide uniformly dispersed in it into a 2.0L cylindrical double-layer quartz reactor through a liquid circulation pump at a speed of 10mL / min. The inner diameter of the quartz reactor is 8cm , the height is 40cm. will contain 100% CO 2 The gas is passed into the bottom of the reaction kettle at a rate of 1.0mL / min. The temperature of the reactor was controlled at 0-5°C by jacket cooling water. Turn on a 1000W medium-pressure mercury lamp to illuminate it for photocatalytic reaction. After the reaction gas flow is stable, the gas is collected at the top of the reactor, and passed through 3M sodium hydroxide alkali solution and anhydrous calcium chloride drying tube in sequence to remove carbon dioxide and water vapor respectively, and the product is the synthesis gas product. Two sets of experiments were carried out in parallel. Three layers of immobilized enzyme screens were evenly placed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com