Erbium-doped calcium titanate light-emitting nanoparticle and preparation method thereof

A technology of nano-particles and calcium titanate, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of high energy consumption, uneven shape, complicated process and other problems of calcium titanate particles, and achieve easy industrial production and good shape Good, low synthesis temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

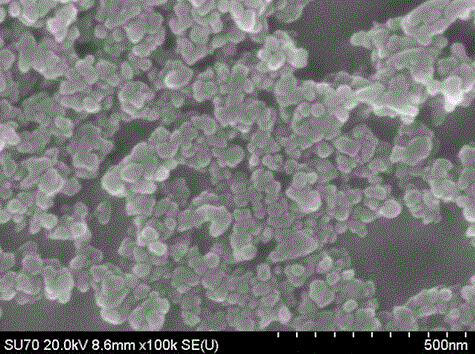

[0021] (1) Dissolve 0.495mmol of calcium nitrate tetrahydrate and 0.005mmol of erbium nitrate pentahydrate in 10ml of absolute ethanol, and mix them thoroughly under magnetic stirring for 30min to obtain solution A.

[0022] (2) Add 5mmol tetrabutyl titanate to 10ml ethanol solution containing 1.0g citric acid, stir for 30min and mix evenly, then add the resulting solution dropwise into solution A with a disposable straw, and stir for 60min.

[0023] (3) Add 4 mmol of auxiliary agent glycerol into the solution obtained in (2), and continue stirring for 1 hour to obtain a precursor solution.

[0024] (4) Put the precursor solution in an oven and dry at 80°C for 12 hours. The obtained powder is sintered at 700° C. for 2 hours in the air, and fully ground after cooling to obtain erbium-doped calcium titanate luminescent nanoparticles.

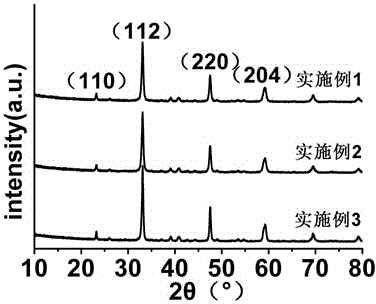

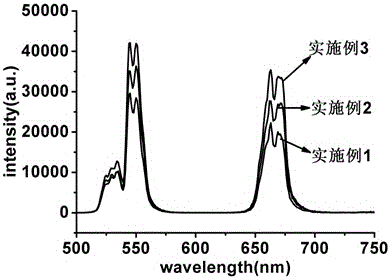

[0025] The general chemical formula of the erbium-doped calcium titanate luminescent nanoparticles prepared in this example is Ca 0.99 TiO 3 :...

Embodiment 2

[0027] (1) Dissolve 0.485mmol of calcium nitrate tetrahydrate and 0.015mmol of erbium nitrate pentahydrate in 20ml of absolute ethanol, and mix them thoroughly under magnetic stirring for 30min to obtain solution A.

[0028] (2) Add 5mmol tetrabutyl titanate to 10ml ethanol solution containing 1.0g citric acid, stir for 30min and mix evenly, then add the resulting solution dropwise into solution A with a disposable straw, and stir for 60min.

[0029] (3) Add 4 mmol of auxiliary agent glycerol into the solution obtained in (2), and continue stirring for 1 hour to obtain a precursor solution.

[0030] (4) Put the precursor solution in an oven and dry at 80°C for 12 hours. The obtained powder is sintered at 700° C. for 2 hours in the air, and fully ground after cooling to obtain erbium-doped calcium titanate luminescent nanoparticles.

[0031] The general chemical formula of the erbium-doped calcium titanate luminescent nanoparticles prepared in this example is Ca 0.97 TiO 3 :...

Embodiment 3

[0033] (1) Dissolve 0.475mmol of calcium nitrate tetrahydrate and 0.025mmol of erbium nitrate pentahydrate in 10ml of absolute ethanol, and mix them thoroughly under magnetic stirring for 30min to obtain solution A.

[0034] (2) Add 5mmol tetrabutyl titanate to 10ml ethanol solution containing 1.0g citric acid, stir for 30min and mix evenly, then add the resulting solution dropwise into solution A with a disposable straw, and stir for 60min.

[0035] (3) Add 4 mmol of auxiliary agent glycerol into the solution obtained in (2), and continue stirring for 1 hour to obtain a precursor solution.

[0036] (4) Put the precursor solution in an oven and dry at 80°C for 12 hours. The obtained powder is sintered at 700° C. for 2 hours in the air, and fully ground after cooling to obtain erbium-doped calcium titanate luminescent nanoparticles.

[0037] The general chemical formula of the erbium-doped calcium titanate luminescent nanoparticles prepared in this example is Ca 0.95 TiO 3 :...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com