A kind of polyphenylene ether copper clad laminate composition

A technology of polyphenylene ether and copper clad laminate, applied in the field of polyphenylene ether copper clad laminate composition, can solve problems such as difficulty in hole metallization and electroplating, different hole metallization of printed boards, and unreliable quality of circuit boards, etc., to achieve improved durability Effects of heat resistance, compensation of processing defects, and good PCB processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

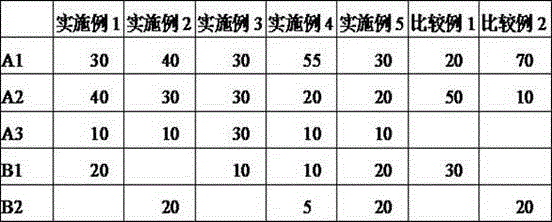

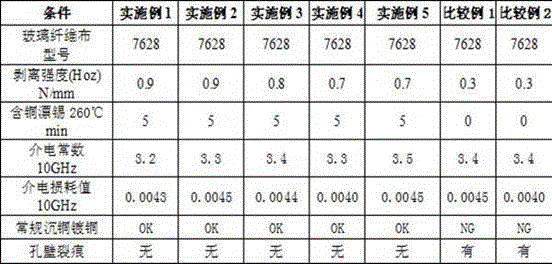

[0020] For the above-mentioned relevant properties, it can be illustrated and described according to the following examples and comparative examples, including the following examples 1-5 and comparative examples 1-2.

[0021] The proportion of its related substances is based on 100 parts by weight of organic substances such as A1, A2 and A3 in the components, and the proportion of other components is the proportion of the total weight of the organic substances.

[0022] (A1) Polyphenylene ether

[0023] (A2) Polyperfluoroethylene emulsion

[0024] (A3) Silicone resin

[0025] (B1) Silica

[0026] (B2) Aluminum oxide

[0027] The laminate base material of the present invention is prepared by mixing and stirring the above-mentioned resin composition, impregnating, gluing, heating and drying, and pressing. The thickness of the copper foil used for pressing is 0.5 ounces (18um thick). Hot press machine, control the temperature of the material at 230-260 ° C, keep it warm for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com