Multi-wire sawing machine spindle system

A multi-wire cutting machine and spindle technology, used in fine working devices, stone processing equipment, manufacturing tools, etc., can solve problems affecting equipment stability, affecting the service life of spindle bearings, etc., to improve service life and prolong service life. , the effect of reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

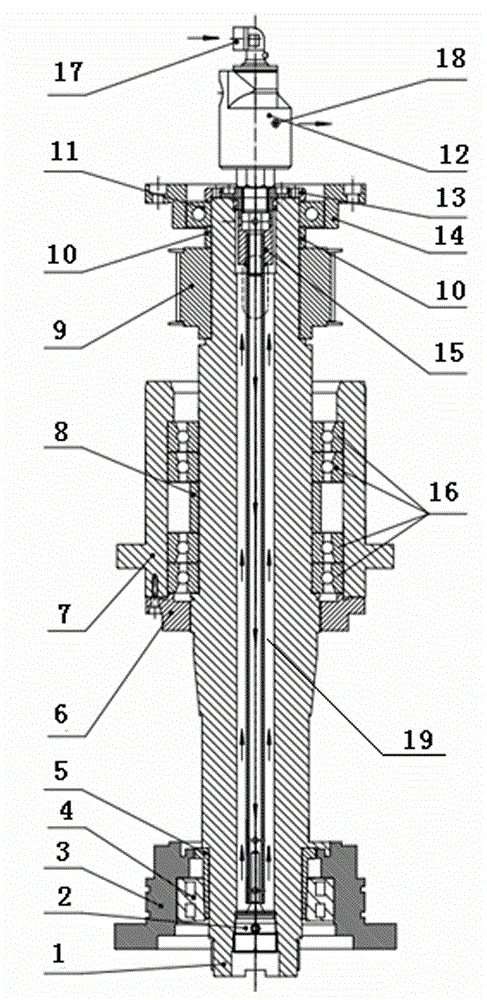

[0010] Referring to the accompanying drawings, a main shaft system of a multi-wire cutting machine is provided with a front end bearing 4 at the front end of the main shaft 1, a front end bushing 5 is provided between the front end bearing 4 and the main shaft 1, and the outer ring of the front end bearing 4 is installed on the front bearing seat 3 Above, there are two sets of main bearings 16 in the middle of the main shaft 1, the two sets of main bearings 16 are separated by an inner bushing 8, the outer ring of the main bearing 16 is installed on the main board bearing seat 7, and the front end of the main bearing 16 is pressed by the gland 6 , the rear of the main shaft 1 is provided with a synchronous pulley 9 and a rear bearing 11, a rear spacer 10 is provided between the rear end bearing 11 and the synchronous pulley 9, a rear cover 13 is installed on the rear end of the main shaft 1, and the outer ring of the rear end bearing 11 Installed on the rear bearing seat 14, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com