Iron and manganese oxide composite modified zeolite as well as preparation method and application thereof

An iron-manganese oxide and composite modification technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of limited processing efficiency and complicated preparation process, and achieve fast adsorption rate and simple preparation method. , the effect of high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

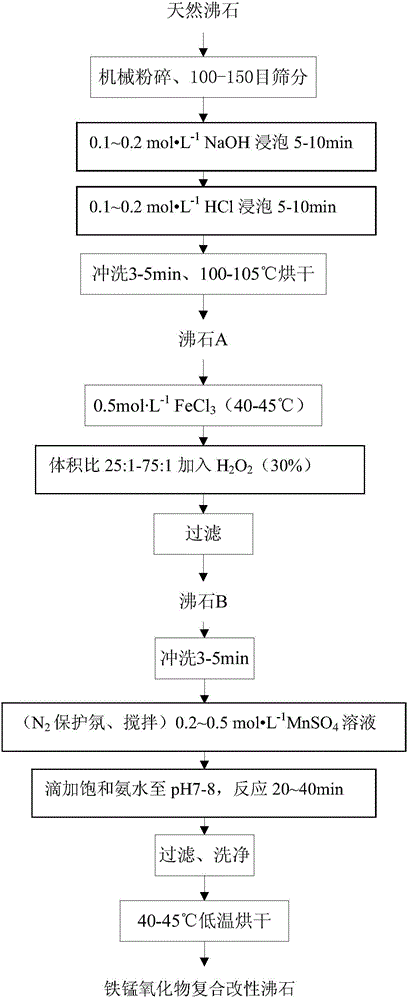

[0034] The invention provides a preparation method of iron-manganese oxide composite modified zeolite, such as figure 1 shown, including the following steps:

[0035] (1) Mechanically pulverize the natural zeolite and sieve it with 100-150 meshes, wash it with distilled water, and use 0.1-0.2mol·L -1 Soak in NaOH solution for 5 to 10 minutes, then filter; then use 0.1 to 0.2 mol·L -1 Soak in HCl solution for 5-10 minutes, filter again, wash with deionized water for 3-5 minutes, and finally dry at 100-105°C to obtain zeolite A;

[0036] (2) Control the reaction temperature at 40-45°C, and add the zeolite A prepared in step (1) to 0.5mol L -1 FeCl 3 In the acidic solution, mix well, add H at a volume ratio of 25:1 to 75:1 2 o 2(30%) solution, reacted 20~30min, filtered to obtain zeolite B;

[0037] (3) After rinsing the zeolite B obtained in step (2) with deionized water for 3 to 5 minutes, add it to deionized water at a weight ratio of 1:100. 2 Add 0.2~0.5mol·L under the...

Embodiment 1

[0041] A preparation method of iron-manganese oxide composite modified zeolite, comprising the following steps:

[0042] (1) Mechanically pulverize the natural zeolite (select a natural mordenite in Heyuan, Guangdong) and wash it with distilled water after sieving with 150 mesh. -1 Soak in NaOH solution for 10min, then filter with vinylon filter cloth, and then use 0.1mol·L -1 Soak in HCl solution for 10 minutes, filter again, wash with deionized water for 5 minutes, and dry at 105°C to obtain zeolite A;

[0043] (2) Control the reaction temperature at 42°C, and add zeolite A to 0.5mol L -1 FeCl 3 In the acidic solution, mix well and add H at a volume ratio of 50:1 2 o 2 (30%) solution, filter after reaction 20min to obtain zeolite B;

[0044] (3) After rinsing zeolite B with deionized water for 5 minutes, add it to deionized water at a weight ratio of 1:100, and 2 Add 0.2mol·L under protective atmosphere and magnetic stirring -1 MnSO 4 The solution starts to appear bl...

Embodiment 2

[0054] A preparation method of iron-manganese oxide composite modified zeolite, the difference between this embodiment and embodiment 1 is the addition of H in step (2) 2 o 2 (30%) volume ratio is 25:1, MnSO in step (3) 4 The solution concentration is 0.5mol L -1 , other steps and parameters are the same as in Example 1.

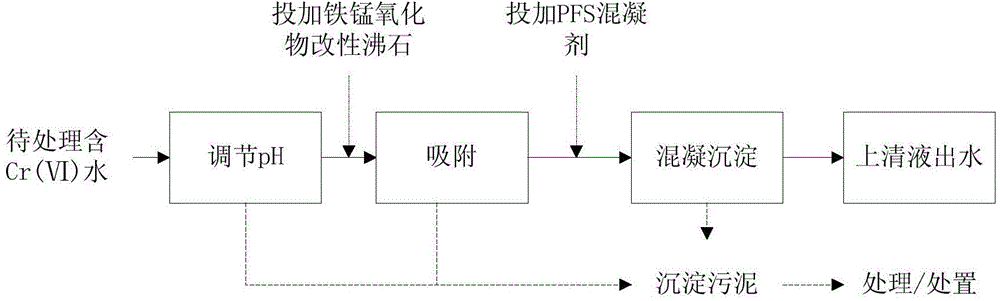

[0055] The Cr(Ⅵ) wastewater discharged from the production workshop of an electroplating enterprise was as high as 13-45 mg·L -1 , pH is 2-4. Use the iron-manganese oxide composite modified zeolite prepared in this example to treat the problem of excessive Cr(VI) in the above-mentioned industrial wastewater: that is, first add lime to adjust the pH to 7.5, and then add 3g L -1 The iron-manganese oxide modified zeolite, the adsorption time is 30min, and then add 5mg·L -1 The PFS coagulant settles for 30 minutes, and the effluent can be reduced to 0.3-0.5 mg·L after filtering through quartz sand -1 , to meet the emission standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com