A kind of sustained-release azithromycin lactobionate injection and preparation method thereof

A technology of azithromycin and lactobionic acid, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., to achieve the effects of reducing the number of medications, uniform particle size distribution, and prolonging the efficacy of the drug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

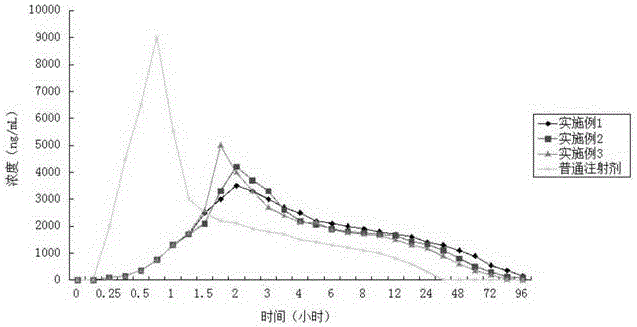

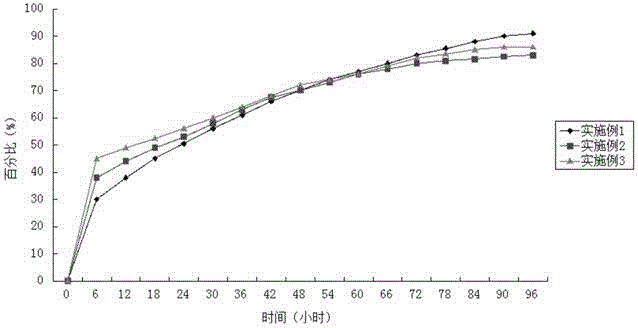

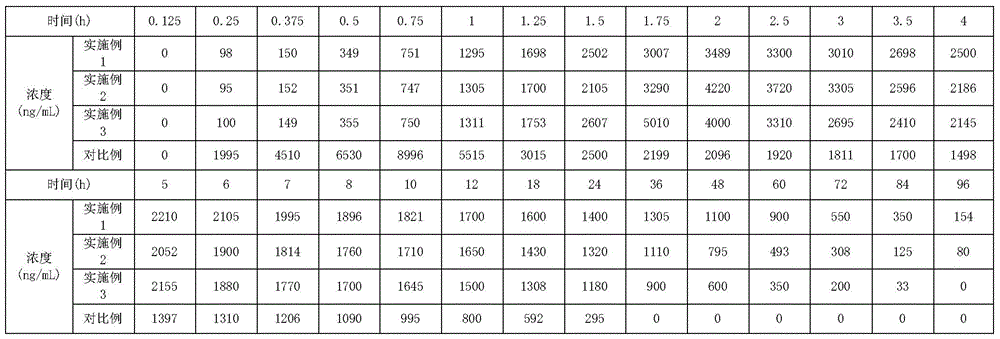

Examples

Embodiment 1

[0033] Weigh 50g of azithromycin lactobionate, 115g of polybenzyl glutamate, and 35g of polyhydroxybutyric acid, dissolve them in chloroform, control the solid concentration of the mixed solution at 35% by weight, stir and add to the polyvinyl alcohol stirred at a speed of 5500RPM In the aqueous solution (viscosity at room temperature is 40mPa·s), continue to stir to form O / W emulsion droplets, and then stir continuously at room temperature at a speed of 800RPM to evaporate the solvent. After the system is solidified, wash with water and dry in vacuum at room temperature to obtain powdery Balls, sterilized;

[0034] Dissolve 15g of mannitol, 8g of carboxymethylcellulose sodium and 1g of Tween-80 in 2000mL of sterile water; centrifuge to remove insoluble matter to prepare a suspension matrix for injection; Suspend the spheres in the suspension matrix, and stir evenly; fill the suspension containing the microspheres into a sterilized vial under stirring; freeze-dry the filled su...

Embodiment 2

[0036] Weigh 50g of azithromycin lactobionate, 130g of polybenzyl glutamate, 20g of polyhydroxybutyric acid, dissolve in chloroform, control the solid concentration of the mixed solution at 35% by weight, stir and add to the polyvinyl alcohol stirred at a speed of 5500RPM In the aqueous solution (viscosity at room temperature is 40mPa·s), continue to stir to form O / W emulsion droplets, and then stir continuously at room temperature at a speed of 800RPM to evaporate the solvent. After the system is solidified, wash with water and dry in vacuum at room temperature to obtain powdery Balls, sterilized;

[0037] Dissolve 15g of mannitol, 8g of carboxymethylcellulose sodium and 1g of Tween-80 in 2000mL of sterile water; remove the insoluble matter by filtration to obtain a suspension matrix for injection; Suspend the microspheres in the suspension matrix and stir evenly; fill the suspension containing the microspheres into a sterilized vial under stirring; freeze-dry the filled susp...

Embodiment 3

[0039] Weigh 50g azithromycin lactobionate, 100g polybenzyl glutamate, 50g polyhydroxybutyric acid, dissolve in chloroform, control the solid concentration of the mixed solution at 35% by weight, stir and add to the polyvinyl alcohol stirred at a speed of 5500RPM In the aqueous solution (viscosity at room temperature is 40mPa·s), continue to stir to form O / W emulsion droplets, and then stir continuously at room temperature at a speed of 800RPM to evaporate the solvent. After the system is solidified, wash with water and dry in vacuum at room temperature to obtain powdery Balls, sterilized;

[0040] Dissolve 15g of mannitol, 8g of carboxymethylcellulose sodium and 1g of Tween-80 in 2000mL of sterile water; centrifuge to remove insoluble matter to prepare a suspension matrix for injection; Suspend the spheres in the suspension matrix, and stir evenly; fill the suspension containing the microspheres into a sterilized vial under stirring; freeze-dry the filled suspension, And det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com